2026 Top High Pressure Relief Valve Solutions for Industrial Applications

In the ever-evolving landscape of industrial applications, high pressure relief valves play a critical role in ensuring safety and reliability. According to the "Global Industrial Valve Market Report 2023," the demand for high pressure relief valves is projected to grow by 8% annually through 2026. This trend underscores the importance of selecting the right solutions for high-pressure systems.

Experts like Dr. Emily Carter, a leading authority in pressure control technologies, emphasize, "The integrity of high pressure relief valves is vital for operational safety." Such insight highlights the urgency of upgrading existing systems. Many industries still rely on outdated designs, risking performance and safety.

However, the market has seen considerable innovation. New materials and designs offer improved durability and efficiency. Yet, not all products meet the industry's stringent standards. Continuous evaluation is essential to ensure that high pressure relief valves can withstand demanding conditions. The future will require a balance between cost and reliability.

Overview of High Pressure Relief Valves in Industrial Applications

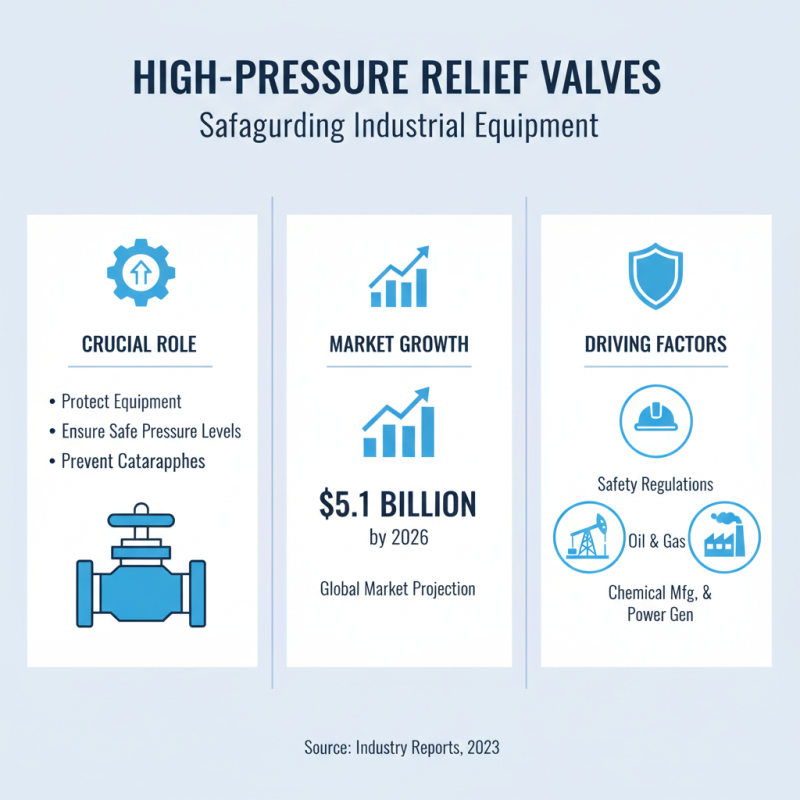

High-pressure relief valves play a crucial role in various industrial applications. They protect equipment by ensuring safe pressure levels. According to recent industry reports, the global market for pressure relief valves is projected to reach $5.1 billion by 2026. This growth is driven by the demand for safety regulations in industries such as oil and gas, chemical manufacturing, and power generation.

These valves function by releasing excess pressure. This can prevent catastrophic failures in pressurized systems. A study highlighted that 30% of pressure-related accidents occur due to valve malfunctions. Regular maintenance is essential in addressing these issues. Inspect the valves routinely to ensure optimal performance.

Tips: Monitor pressure levels closely. Understand the pressure limits of your system. Identify signs of wear early to avoid costly repairs later. Frequent checks can help mitigate risks associated with high-pressure systems. Overall, robust management of pressure relief valves is necessary for operational safety and efficiency. Balancing costs with safety measures is always a challenge. Investing in quality valves and maintenance may avoid future failures.

Key Features and Benefits of High Pressure Relief Valves

High pressure relief valves are crucial in industrial settings. They help prevent equipment failures and protect personnel. These valves automatically release pressure when it exceeds safe levels. This function is vital in sectors like oil and gas, chemical manufacturing, and power generation.

The key features encompass robust construction and quick response time. Many modern valves use advanced materials. This ensures they withstand harsh environments. The benefits are clear. They enhance safety, improve reliability, and reduce downtime. Yet, it’s important to note that not all valves are created equal. Some may not respond as quickly as needed. Regular maintenance is essential to keep them functioning effectively.

Another critical aspect is the valve sizing. An incorrectly sized valve can lead to serious problems. It may release pressure too early or too late. This can result in equipment damage or safety hazards. Taking the time to evaluate specific application needs is required. Skipping this step can be detrimental. Understanding the unique requirements of each system is as important as choosing the right valve.

Leading Manufacturers of High Pressure Relief Valves for 2026

As industries evolve, high pressure relief valves play a crucial role in ensuring safety and efficiency. These valves protect equipment by releasing excess pressure. Their design and functionality have advanced significantly. This creates a need for a closer look at leading valve manufacturers as we approach 2026. Many companies focus on innovation but also face challenges in reliability and cost-effectiveness. There is a constant balancing act between performance and affordability.

When searching for high pressure relief valves, it’s essential to consider several aspects. Efficiency and durability are vital. However, manufacturers often struggle with maintaining both over time. It is important to choose products that meet regulatory standards yet offer practical solutions. Some manufacturers excel in technology but may overlook user experience. Feedback from users is crucial to help them improve.

In 2026, the market will likely reflect these evolving needs. Manufacturers must adapt to new technologies and materials. Sustainability may become a greater concern as industries shift focus. The path ahead is exciting, yet it requires reflection on lessons learned from past experiences. Embracing feedback and fostering collaboration could lead to more effective solutions.

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

| Model | Pressure Range (psi) | Material | Connection Type | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Model A | 50-1500 | Stainless Steel | Threaded | -20 to 400 | Chemical Processing |

| Model B | 100-2000 | Carbon Steel | Flanged | 0 to 250 | Oil and Gas |

| Model C | 300-2500 | Brass | Socket Weld | -10 to 300 | Power Generation |

| Model D | 150-2200 | Alloy Steel | Tri-Clamp | -40 to 350 | Pharmaceutical |

| Model E | 80-1800 | Polymer | Compression Fit | -20 to 260 | Food Processing |

Innovative Technologies in High Pressure Relief Valve Solutions

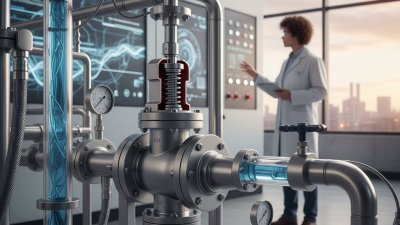

High pressure relief valves play a crucial role in industrial safety. They prevent equipment damage and protect personnel. Innovative technologies are paving the way for more reliable and efficient solutions. Smart sensors and advanced materials are at the forefront of this evolution.

Using predictive analytics, these valves can anticipate pressure changes. This allows for timely adjustments, enhancing safety mechanisms. Wireless communication capabilities enable remote monitoring. Operators can act quickly, reducing risks and minimizing downtime.

**Tips:** Regular maintenance is key. Check your valves often to ensure they function correctly. Monitor for any signs of wear or malfunction. Training staff on emergency protocols can save lives. Awareness is critical in high-pressure environments. Create a culture of safety in your facility.

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

This chart displays the performance of various high pressure relief valve solutions in industrial applications for the year 2026. The data reflects the effectiveness based on different criteria including reliability, response time, and maintenance needs.

Best Practices for Maintenance and Safety of Pressure Relief Valves

Maintaining pressure relief valves is crucial for safety in industrial applications. According to industry reports, improper maintenance can lead to system failures. In fact, up to 80% of pressure relief valve failures are attributed to lack of proper care. Regular inspections and maintenance practices are essential. These valves must be tested periodically to ensure they function correctly under pressure.

Tip: Always document maintenance work. Keeping records helps track performance and identify patterns over time. This practice often uncovers recurring issues that may require deeper analysis.

Users should be aware that accumulation of debris can impair valve function. Dirt and corrosion can build up, leading to valve sticking or premature failure. As equipment ages, the risk increases. Regular cleaning and checks for wear can mitigate these risks.

Tip: Implement a visual inspection routine. A quick look can reveal leaks or corrosion early, preventing significant failures later.

Addressing valve issues promptly is vital. Small problems can turn into major safety hazards. Neglecting routine maintenance could jeopardize worker safety. In some cases, it can impact entire production lines. Adopting best practices is a step toward consistency and reliability in operations.

Related Posts

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

10 Essential Tips for Choosing the Right Pressure Release Valve

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips

-

How to Choose a Low Pressure Relief Valve for Your System Needs