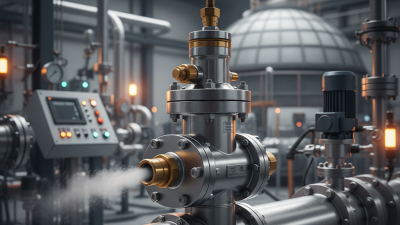

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

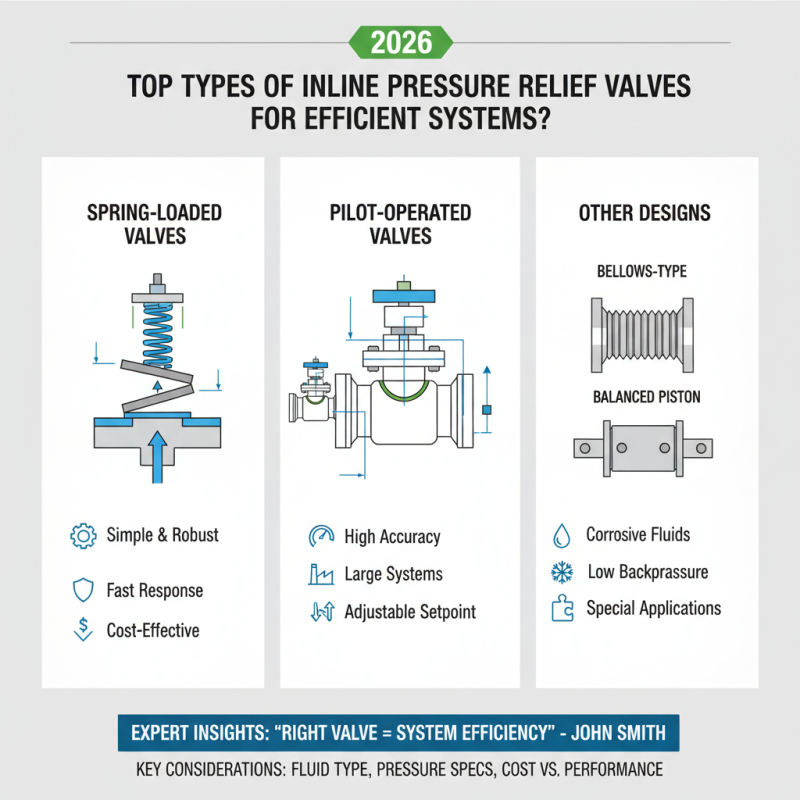

In the evolving landscape of industrial systems, the efficiency of pressure management is crucial. Inline pressure relief valves are essential components. As John Smith, a leading expert in fluid dynamics, states, "The right inline pressure relief valve can make or break system efficiency." This highlights the importance of selecting the appropriate valve type.

As 2026 approaches, advancements focus on various designs. From spring-loaded to pilot-operated options, each has unique benefits. However, the perfect choice may vary based on specific applications. Some industries may struggle with valve selection due to limited understanding. The consequences of a poor choice can lead to system failures and increased costs.

It's essential to recognize the potential drawbacks. Not every inline pressure relief valve suits every task. Understanding fluid characteristics and pressure requirements is vital. Companies often overlook these details, leading to inefficiencies. Considering expert advice can bridge this knowledge gap. Balancing performance, safety, and cost remains a challenge in evolving systems.

2026 Trends in Inline Pressure Relief Valves Industry Design and Technology

The landscape of inline pressure relief valves is evolving rapidly in 2026. Innovative designs are becoming more prevalent. Many industries are focusing on efficiency and safety, pushing for new technology.

One prominent trend is the use of advanced materials. Manufacturers are now exploring lightweight compositions. These materials not only improve performance but also reduce wear and tear. Enhanced durability is critical for high-pressure applications. Systems are challenged to handle various pressures, leading to unique designs.

Incorporating smart technology is another major development. Sensors and monitoring systems are now common in new models. They provide real-time data, enabling better decision-making. However, there is a learning curve. Companies must adapt to these technologies to maximize their benefits. Balancing innovation with reliability is an ongoing challenge. Adjustments to current systems may be necessary for optimal functionality.

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems

| Type of Valve | Pressure Range (psig) | Temperature Range (°F) | Material | Applications |

|---|---|---|---|---|

| Spring Loaded | 50 - 3000 | -40 to 350 | Steel, Brass | Oil & Gas, Water Systems |

| Pneumatic | 20 - 1500 | 0 to 300 | Aluminum, Plastic | Chemical Processing |

| Hydraulic | 100 - 5000 | -20 to 250 | Stainless Steel | Manufacturing, Automotive |

| Pilot Operated | 100 - 2000 | -40 to 400 | Nickel Alloy, Steel | Power Generation, Marine |

Key Characteristics of Inline Pressure Relief Valves for Optimal Performance

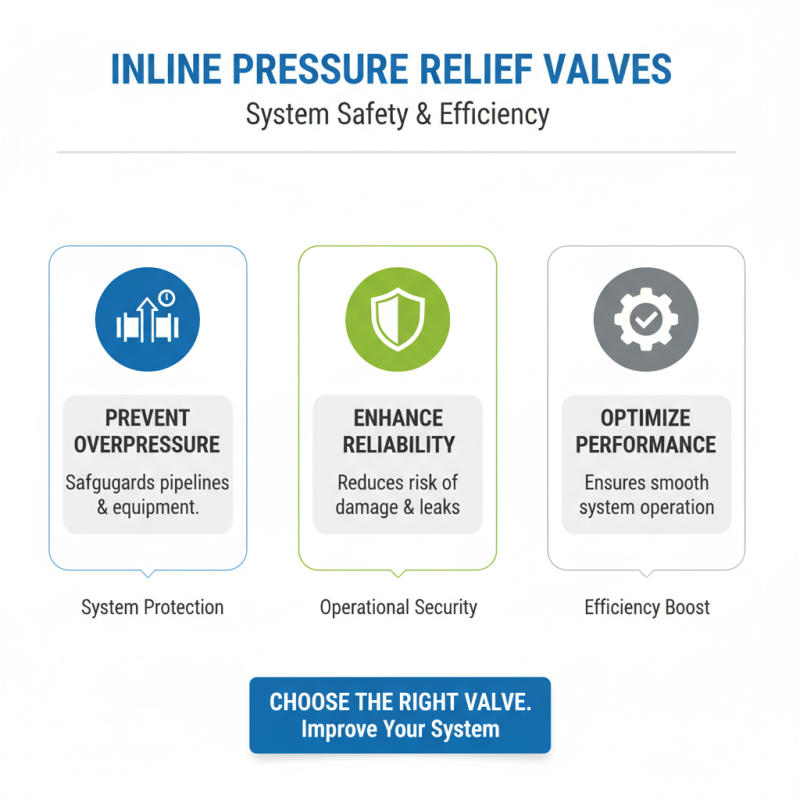

Inline pressure relief valves are critical for system safety and efficiency. These valves prevent overpressure situations in pipelines and equipment. The right choice can enhance system reliability.

Key characteristics include responsiveness and accuracy. A quick reaction to changes in pressure can protect sensitive equipment. The design should minimize pressure drop when in operation. This ensures optimal flow and system performance.

Durability also matters. These valves must withstand harsh conditions. Materials used should resist corrosion and wear. Regular maintenance is necessary to maintain performance. Sometimes, unnoticed issues may arise. This can lead to larger problems down the line. Understanding these aspects is key to achieving optimal performance.

Performance Metrics: Efficiency Ratings of Leading Pressure Relief Valve Types

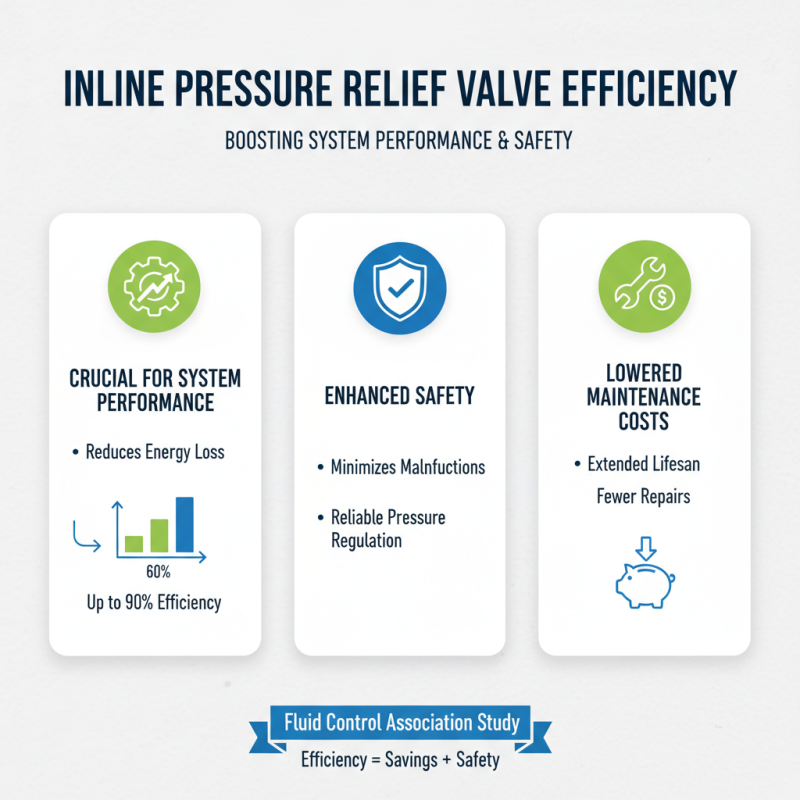

The efficiency ratings of inline pressure relief valves are crucial for system performance. Recent industry reports indicate that optimal efficiency can enhance overall safety and reduce maintenance costs. For instance, a study by the Fluid Control Association revealed that certain valve types can achieve up to 90% efficiency in specific applications. These valves can significantly minimize energy loss during operation.

However, not all valves perform equally. The data shows that variations in materials and design impact efficiency ratings. Some valves have a tendency to stick or fail under high pressure, resulting in unpredictable performance. The American Society of Mechanical Engineers (ASME) highlights that approximately 15% of pressure relief valves underperform, leading to increased operational risks. Users must assess valve quality and efficiency ratings carefully to ensure reliability in critical systems.

In modern systems, the integration of smart technology is essential. Smart pressure relief valves, equipped with sensors, offer real-time data and monitoring. This innovation can improve maintenance schedules and enhance system efficiency. Nonetheless, the initial investment may be higher. Balancing cost and performance remains a challenge for many operators seeking efficient solutions.

Industry Applications: Where Inline Pressure Relief Valves Make a Difference

Inline pressure relief valves play a crucial role across various industries. In oil and gas, they help manage pressure surges. These surges can damage equipment if left unchecked. Properly functioning valves prevent costly failures. They ensure the safe operation of pipelines.

In the manufacturing sector, these valves are equally important. They maintain safe pressure levels in chemical processes. Extreme pressure can lead to hazardous situations. A malfunction can cause spills or explosions, endangering lives and the environment. Regular maintenance and monitoring are essential.

Even with advancements, challenges remain. Some systems still face pressure fluctuations. This unpredictability can strain equipment. Industries need to reflect on their valve choices. Ensuring reliability should always be a priority. Understanding specific application needs can lead to better outcomes.

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems

This chart represents the various types of inline pressure relief valves and their applications in different industries for the year 2026.

Regulatory Standards Impacting Inline Pressure Relief Valve Selection in 2026

Regulatory standards play a crucial role in selecting inline pressure relief valves. In 2026, manufacturers must adhere to updated regulations. These standards aim to ensure safety and reliability in various industries. Violating these regulations could lead to severe consequences. Companies must be aware of local and international guidelines.

Selecting the right valve isn’t just about compliance. It requires a deep understanding of the application. Factors such as pressure range and material compatibility matter. Some valves may not perform well in extreme conditions. This could create operational risks. Addressing these challenges is essential for efficiency.

Designing systems that accommodate such regulations can be complex. For example, some engineers might overlook environmental factors. This oversight can affect valve performance. Regular audits can help identify gaps in compliance. Continuous learning and adjustments are necessary for improvement.

Related Posts

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

How to Choose a Low Pressure Relief Valve for Your System Needs

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications