How to Adjust an Air Compressor Relief Valve for Optimal Performance?

Understanding how to adjust an air compressor relief valve is crucial for optimal performance. According to John Smith, a lead engineer at AirTech Solutions, "A well-adjusted relief valve can prevent equipment damage and enhance efficiency." This highlights the importance of this small but significant component.

When improperly set, the air compressor relief valve can lead to pressure fluctuations. These fluctuations may result in inconsistent tool performance or even costly repairs. Regular adjustment of the relief valve can help maintain steady pressure levels. Observations from industry veterans suggest dedicating a few minutes monthly to check these settings.

Yet, adjusting the air compressor relief valve is not always straightforward. Factors such as wear and tear or environmental changes may affect its functionality. Many users often overlook this maintenance, leading to inefficiencies. It's vital to be proactive, stay aware, and adjust the valve correctly to ensure reliable operation.

Understanding the Function of an Air Compressor Relief Valve

The relief valve in an air compressor plays a crucial role in maintaining safe operating conditions. It prevents excessive pressure buildup. When the pressure exceeds a specific limit, the relief valve activates, releasing air and protecting the compressor from damage. According to industry reports, nearly 30% of compressor failures are due to improper pressure settings. Understanding how this component functions is essential for optimal performance.

Tips: Regularly check your relief valve for signs of wear. A malfunctioning valve may not release pressure effectively. This could lead to system failures. Also, ensure it's properly adjusted to prevent leakage. An improperly set valve can compromise safety.

Additionally, it's vital to maintain the air compressor's pressure settings. They should align with the manufacturer's recommendations. Adjusting the relief valve to the correct pressure can enhance efficiency. Manufacturers suggest keeping pressure within recommended ranges. This ensures steady performance. Regular monitoring of pressure levels can help avoid unexpected breakdowns. Consider developing a routine schedule to check these settings.

Air Compressor Relief Valve Pressure Settings

Identifying the Right Pressure Settings for Your Compressor

Selecting the right pressure settings for your air compressor is crucial. An air compressor typically operates efficiently within a range of 70 to 90 psi. However, the optimal setting can vary based on the tools being used. For instance, pneumatic tools often require specific pressure to function correctly. According to industry reports, improper settings can lead to tool malfunction or decreased efficiency.

Pressure settings should be adjusted periodically. Many users overlook this aspect, leading to underperformance. A study found that almost 30% of users fail to maintain their compressors. This neglect can result in increased wear and tear. It is essential to remember that running a compressor at higher than necessary pressures can consume more energy, impacting overall operational costs.

Monitoring performance metrics is vital as well. A gauge can help track if the pressure is consistent. If fluctuations occur, recalibrating the relief valve may be necessary. Regular checks on these parameters ensure that your compressor runs smoothly, enhancing longevity. Adjustments may feel daunting, but they can lead to significant efficiency gains. Ignoring them may lead to frustrating downtime later.

How to Adjust an Air Compressor Relief Valve for Optimal Performance?

| Parameter | Recommended Setting | Impact on Performance |

|---|---|---|

| Normal Operating Pressure | 90-120 PSI | Ensures efficient operation and longevity of the compressor. |

| Maximum Pressure Setting | 125-150 PSI | Prevents overloading and potential damage to compressor components. |

| Relief Valve Pressure | 10% above normal operating pressure | Safeguards against excessive pressure by releasing air when necessary. |

| Adjustment Frequency | Every 6 months | Regular checks prevent drift in pressure settings and ensure optimal performance. |

| Environmental Temperature | 50°F - 100°F | Affects pressure settings; extreme temperatures can impair functionality. |

Steps to Safely Adjust the Relief Valve Pressure

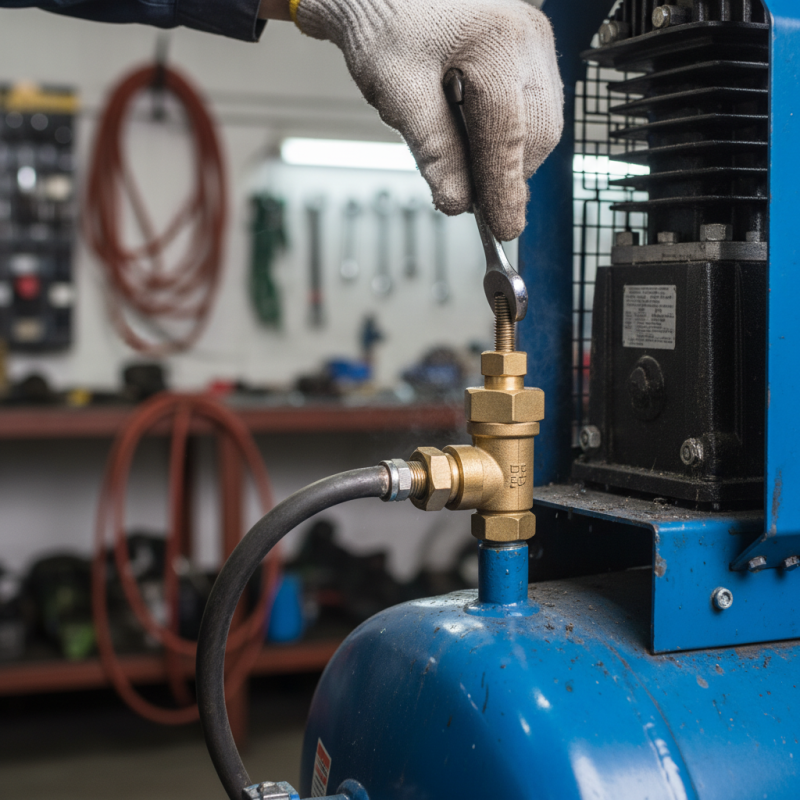

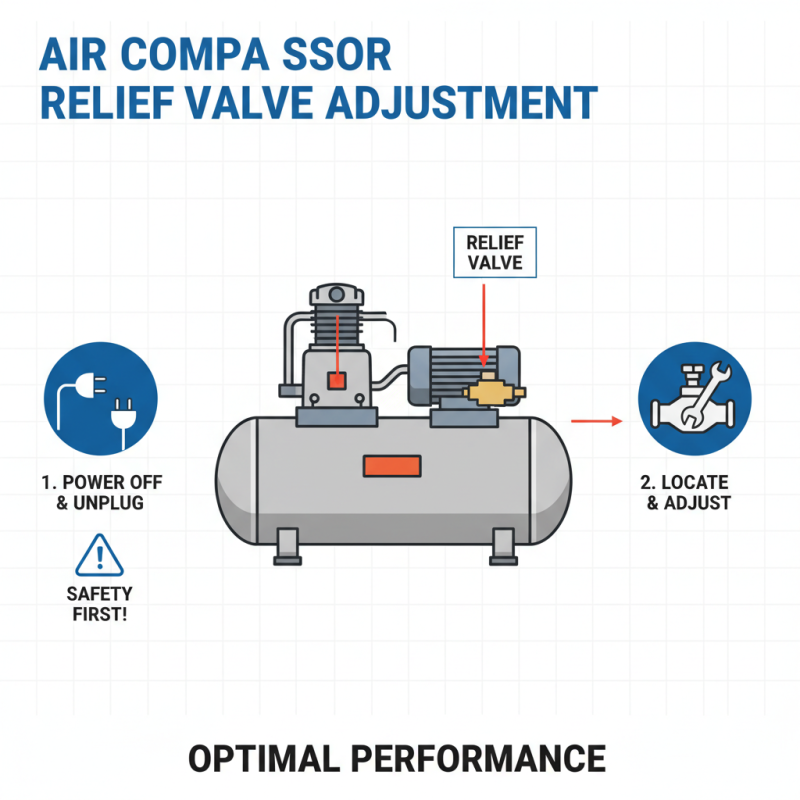

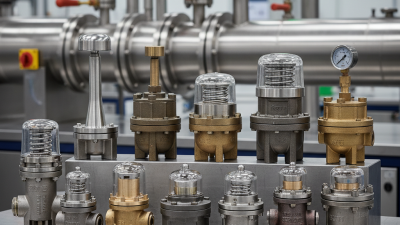

Adjusting an air compressor relief valve is essential for optimal performance. To begin this process safely, ensure the compressor is turned off and unplugged. This step is critical. Safety should always come first. Before making any adjustments, locate the relief valve. It is usually a small brass valve on the compressor's tank.

Once you find it, prepare to make adjustments. Use a pressure gauge to monitor the current pressure setting. This equipment is important for accuracy. Rotate the adjustment screw slowly. Increase or decrease the pressure as needed. Be careful to not exceed the manufacturer's specifications. Over-setting could lead to hazardous situations.

After making your adjustments, test the compressor. Plug it in and let it run for a while. Listen for unusual sounds. If the compressor doesn’t perform well, reassess your adjustments. This part can take time. Remember, finding the perfect pressure can be a process. Keep safety at the forefront, and don’t rush the steps. Each adjustment brings you closer to optimal performance.

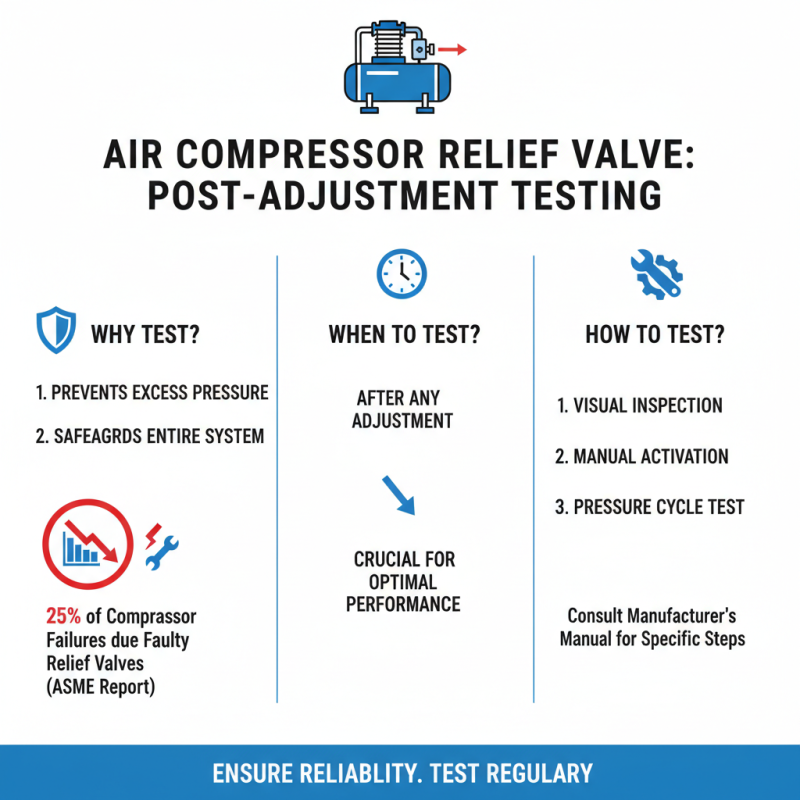

Testing the Relief Valve After Adjustment for Performance

Testing the relief valve after adjustment is crucial for ensuring optimal performance in air compressors. A properly functioning relief valve prevents excess pressure, safeguarding the entire system. According to a report by the American Society of Mechanical Engineers, nearly 25% of compressor failures are linked to faulty relief valves. Thus, after making any adjustments, one should perform a series of tests.

Start by monitoring the pressure gauge during operation. Ideal relief valve settings should allow the compressor to build to its maximum pressure without triggering the relief valve prematurely. If the valve activates too soon, adjustments are necessary. Conversely, if it does not activate at the designed pressure, this may indicate a need for recalibration. Regular testing can determine if the valve maintains performance over time, especially considering that the most common issues can be wear and debris blocking the mechanism.

During testing, listen for any unusual sounds, such as hissing or rattling. These could point to mechanical failures. Visual inspections should not be overlooked either. Examine for any signs of corrosion or debris that could impede performance. Oftentimes, operators may overlook these details, leading to inefficiencies and potential breakdowns. Implementing a consistent testing routine helps in identifying and rectifying such problems early on.

Common Issues and Troubleshooting Tips for Relief Valves

When it comes to air compressors, the relief valve plays a crucial role in maintaining safety and efficiency. Common issues arise when this valve fails to operate correctly, leading to potential over-pressurization. In fact, reports indicate that improper adjustments can reduce compressor efficiency by up to 30%. Regular maintenance is essential to prevent such problems.

One common issue is a leaking relief valve. This can occur due to debris buildup or wear over time. Ensure the valve is clean and functional by regularly inspecting it. Isolation and cleaning of the valve can often resolve minor leaks. Remember, though, that sometimes a simple adjustment won’t be enough. In cases of severe leakage, replacement may be necessary.

Tips: Check the valve's pressure settings regularly. Use a calibrated gauge for accuracy. Listen for unusual sounds; this can signal malfunction.

Another frequent concern is valve sticking. Environmental factors, such as humidity and temperature, affect performance. This can lead to improper operation. Lubrication should be done as per guidelines, but over-lubricating can attract dirt. This may cause more harm than good. Stay mindful of the balance between adequate lubrication and contamination.

Related Posts

-

Understanding the Importance of Air Compressor Relief Valve in 2025 Top Models

-

Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

How to Choose the Best Safety Relief Valve for Your Application

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications