Top 10 Benefits of Using Pressure Vacuum Relief Valves for Your Industry

In today’s industrial landscape, ensuring the safety and integrity of process equipment is paramount. Among the various tools utilized to enhance safety mechanisms, the pressure vacuum relief valve (PVRV) stands out as an essential component. According to a recent report by the Global Pressure and Vacuum Relief Valve Market, the demand for PVRVs is projected to grow at a compounded annual growth rate (CAGR) of 5.6% over the next five years, reflecting their critical role in preventing overpressure and vacuum situations that could lead to catastrophic failures in storage tanks and other equipment.

Industry expert Dr. Elizabeth Carter notes, “The implementation of pressure vacuum relief valves is a proactive measure that significantly increases the safety of storage and transportation systems.” By allowing for the safe venting of excess pressure and preserving structural integrity, PVRVs not only protect valuable assets but also ensure compliance with stringent regulatory standards. The multifaceted benefits of installing these valves extend beyond mere functionality; they enhance operational efficiency and contribute to the overall resilience of industrial processes. Thus, understanding the top advantages of incorporating pressure vacuum relief valves is vital for industry professionals aiming to safeguard their operations in an ever-evolving regulatory environment.

Benefits of Pressure Vacuum Relief Valves in Industrial Applications

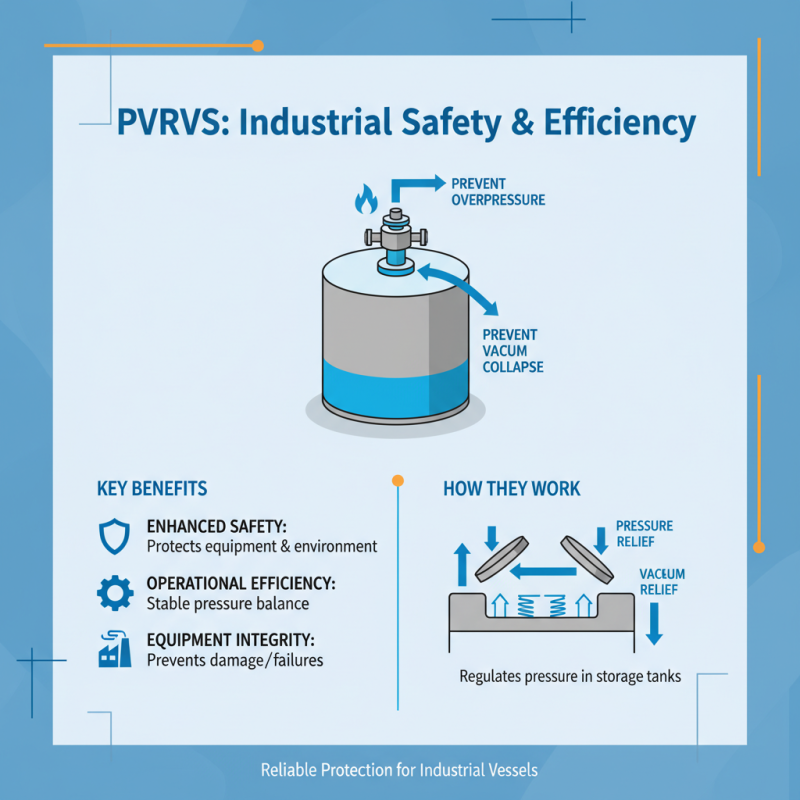

In industrial applications, pressure vacuum relief valves (PVRVs) offer crucial benefits that enhance safety and operational efficiency. These valves are designed to maintain the balance of pressure within storage tanks and vessels, preventing the risk of collapse or uncontrolled venting. By managing pressure fluctuations, PVRVs ensure the integrity of the equipment and protect the surrounding environment from potential hazards associated with overpressure and vacuum conditions.

Moreover, PVRVs contribute to operational efficiency by reducing downtime related to equipment failure. By alleviating excessive pressure, these valves minimize the risk of costly incidents that could lead to equipment damage or system shutdowns. This reliability translates to greater productivity and cost savings for businesses, as processes can run smoothly without interruptions caused by pressure-related issues.

Tips for implementation: When selecting PVRVs, consider factors such as the specific materials handled, the pressure range, and the size of the equipment. Regular maintenance and testing of these valves are also essential to ensure they operate correctly and provide maximum protection. Additionally, consulting with engineering experts can help optimize the design and integration of PVRVs into existing systems, further enhancing their effectiveness in your industrial applications.

Enhancing Safety Standards in Chemical Storage with PV Relief Valves

Pressure vacuum relief valves (PVRVs) play a crucial role in enhancing safety standards within the chemical storage industry. These devices are designed to maintain the pressure balance within storage tanks, preventing the potentially hazardous buildup of pressure or vacuum conditions. By automatically relieving excess pressure or allowing air to enter, PVRVs help mitigate risks associated with tank overpressure or implosion, thus protecting both the facility and the surrounding environment from catastrophic failures.

In addition to their protective functions, PVRVs significantly contribute to compliance with industry safety standards and regulations. By incorporating these valves into chemical storage systems, organizations can demonstrate their commitment to proactive safety measures, reducing the likelihood of spills and leaks. Furthermore, regular maintenance and inspection of PVRVs can identify potential weaknesses in the system, allowing for timely interventions and enhancing overall operational safety. Through the strategic implementation of pressure vacuum relief valves, industries can ensure a safer working environment while promoting the responsible management of chemical substances.

Top 10 Benefits of Using Pressure Vacuum Relief Valves for Your Industry - Enhancing Safety Standards in Chemical Storage with PV Relief Valves

| Benefit | Description | Impact on Safety | Industry Application |

|---|---|---|---|

| Pressure Control | Maintains optimal pressure levels within storage tanks. | Reduces the risk of tank rupture or explosion. | Chemical Manufacturing |

| Vacuum Protection | Prevents the formation of a vacuum that could collapse storage tanks. | Enhances structural integrity of tanks. | Petrochemical Industry |

| Emergency Relief | Provides a quick path for excess pressure in emergencies. | Minimizes chances of hazardous incidents. | Oil and Gas |

| Environmental Protection | Prevents leakage of harmful substances into the environment. | Assures compliance with environmental regulations. | Chemical Storage |

| Operational Efficiency | Minimizes downtime caused by pressure buildup. | Enhances overall production workflows. | Manufacturing Plants |

| Cost Reduction | Lowers maintenance costs associated with tank inspections. | Improves financial performance. | Industrial Storage Facilities |

| Improved Safety Standards | Aligns with industry best practices for safety. | Strengthens safety culture in organizations. | Various Industries |

| Regulatory Compliance | Ensures adherence to national and international safety standards. | Avoids penalties and legal issues. | All Chemical Industries |

| Versatility | Applicable across different types of storage systems. | Increases safety measures in diverse settings. | Multi-Industry Use |

| Enhanced Monitoring | Facilitates better monitoring of pressure conditions. | Optimizes safety interventions. | Process Industries |

Reducing Environmental Risks and Emissions through PV Valve Utilization

Pressure vacuum relief valves (PV valves) play a critical role in enhancing safety and reducing environmental risks in various industries. By regulating pressure and vacuum levels within storage tanks and other containment systems, these valves help prevent catastrophic failures that can lead to leaks and spills. The utilization of PV valves significantly minimizes the release of harmful emissions into the atmosphere, ensuring compliance with environmental standards and protecting air quality.

One of the key benefits of using pressure vacuum relief valves is the reduction of risks associated with volatile organic compounds (VOCs) emissions. By maintaining appropriate pressure levels, PV valves limit the potential for gases to escape during tank filling, emptying, and thermal expansion. This is not only vital for meeting regulatory requirements but also for fostering a safer working environment for employees and surrounding communities.

Tips for effective PV valve utilization include regularly inspecting and maintaining the valves to ensure they function properly under varying conditions. It is also beneficial to conduct routine training for staff on the correct procedures for operating and monitoring these systems. By prioritizing the functionality of PV valves and investing in employee education, industries can further enhance their commitment to reducing environmental impacts while promoting a culture of safety.

Incorporating pressure vacuum relief valves into industry practices not only minimizes emissions but also demonstrates a proactive approach toward environmental stewardship. By understanding the significance of these valves and implementing best practices, businesses can contribute to a healthier planet while safeguarding their operations.

Top 10 Benefits of Using Pressure Vacuum Relief Valves for Your Industry

Improving Operational Efficiency in Oil and Gas Industries with PV Relief Valves

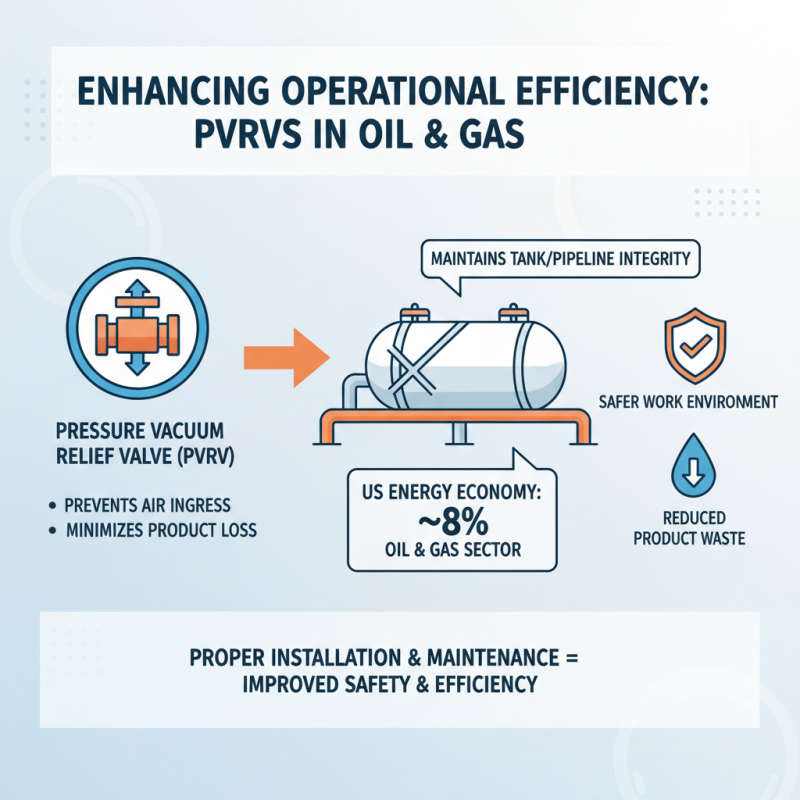

Pressure vacuum relief valves (PVRVs) play a crucial role in enhancing operational efficiency within the oil and gas industries. These valves are designed to prevent the ingress of air and the loss of product during storage and transport, maintaining the integrity of tanks and pipelines. According to a report by the U.S. Energy Information Administration, the oil and gas sector accounts for about 8% of the total U.S. economy, emphasizing the importance of efficient operation in this industry. Proper installation and maintenance of PVRVs can significantly reduce the risk of accidents and losses, ensuring a safer working environment for employees and minimizing product waste.

Furthermore, by effectively regulating pressure dynamics during filling and emptying processes, PVRVs contribute to optimizing the operational lifecycle of equipment. A study from the Gas Technology Institute underscores that effective pressure management can improve process reliability by up to 25%. This reliability aids in preventing costly downtimes and enhances the overall productivity of industrial operations. Such benefits contribute not only to direct financial savings but also to a reduced environmental footprint, aligning with the industry's increasing focus on sustainability and regulatory compliance. By investing in advanced pressure vacuum relief valves, companies can expect to see marked improvements in their operational efficiencies and long-term viability in a competitive market.

Meeting Regulatory Compliance Requirements with Effective PV Relief Systems

Effective pressure vacuum relief valves (PV relief systems) are essential for industries that must comply with strict regulatory standards. These valves play a critical role in managing tank pressures during both filling and emptying operations, ensuring that excess pressure or vacuum does not compromise the integrity of storage vessels. By incorporating reliable PV relief systems, companies can prevent dangerous over-pressurization or implosion, thereby protecting both personnel and equipment. This adherence to safety standards not only enhances operational efficiency but also minimizes the risk of costly incidents that could lead to regulatory scrutiny.

Moreover, regular maintenance and testing of PV relief systems ensure that they function correctly and meet compliance requirements. Industries are often subject to audits and inspections, and demonstrating a proactive approach to safety through effective PV relief mechanisms can lead to improved relationships with regulatory bodies. Meeting these compliance benchmarks can also enhance public perception and bolster a company’s reputation as a responsible player in the industry. Therefore, investing in high-quality pressure vacuum relief valves is not merely a safety measure but a strategic decision that supports long-term compliance and operational success.

Related Posts

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips

-

2025 Guide: How to Choose the Right Pressure Valve for Your Needs

-

Top 10 Common Questions About Boiler Relief Valves Answered

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Safety Valve Types for Optimal Pressure Control and System Safety