10 Best Adjustable Pressure Relief Valves You Need to Know?

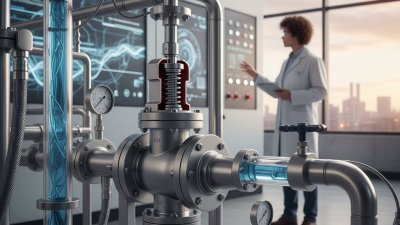

In the world of fluid control, the adjustable pressure relief valve (APR valve) plays a crucial role. These devices help maintain safe pressure levels in various systems, mitigating risks of equipment failure and ensuring operational efficiency. According to a recent report by the International Society for Fluid Mechanics, improper pressure management can lead to costly downtime. Expert John M. Sidwell emphasizes the importance of APR valves, stating, “A reliable adjustable pressure relief valve is the backbone of any pressure management system.”

The market for adjustable pressure relief valves has seen significant growth. By 2025, it is projected to reach over $1 billion, driven by industrial expansion and the rising need for safety standards. However, the selection process can be overwhelming. Many users struggle to identify the best products for their needs, leading to potential issues. Choosing the wrong valve can have serious repercussions, including leaks or system failures.

Understanding the specifics of adjustable pressure relief valves is vital. Their design varies greatly, affecting performance. While some features are standard, others are customizable based on application. Ultimately, the right choice hinges on comprehension of both product specifications and individual system requirements. Thus, investing time in research is essential for optimal performance and safety.

Introduction to Adjustable Pressure Relief Valves

Adjustable pressure relief valves play a crucial role in various industries. They are designed to regulate and control pressure within systems, ensuring safety and efficiency. According to industry reports, improper pressure control can lead to costly downtime. In fact, an estimated 20% of industrial failures are linked to pressure regulation issues.

These valves can be adjusted to meet specific system requirements. They not only prevent potential hazards but also improve operational performance. Research indicates that using the right adjustable valve can enhance system efficiency by up to 15%. This feature is particularly important in sectors such as oil and gas, pharmaceuticals, and manufacturing, where precision is vital.

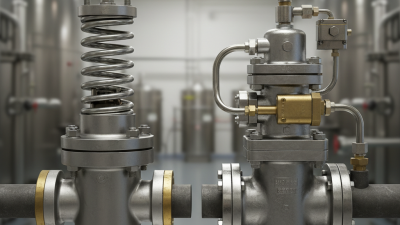

However, not all adjustable pressure relief valves are created equal. Selecting the right type often proves challenging. Factors to consider include material compatibility, flow rates, and response time. A mistake in choice can result in serious repercussions. In some cases, companies overlook the need for regular maintenance checks. This can lead to valve failure and increased operational risks. Addressing these issues is essential for long-term reliability and safety.

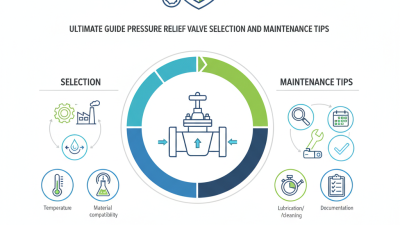

Key Features to Consider When Choosing Pressure Relief Valves

When selecting adjustable pressure relief valves, a few key features are crucial. The set pressure is important. It should align closely with the system's operational pressure. According to a recent industry report, a mismatch can lead to equipment failures or unsafe conditions. This occurs when the valve either opens too late or not at all.

Material selection is another aspect that cannot be overlooked. Valves must endure specific chemical environments. Choosing the wrong material can lead to corrosion. This compromises performance and safety. A study indicated that nearly 30% of valve failures were due to inappropriate material usage. Additionally, consider the valve’s size. A valve that is too small can restrict flow, while one that is too large may not maintain adequate pressure.

Ease of adjustment is worth noting. Users often struggle with complicated mechanisms. A user-friendly design enhances performance reliability. Also, ensure the valve meets industry standards. Compliance with these standards is vital for safety and efficiency. Approximately 15% of all valve incidents stem from non-compliance. These features should be weighed carefully to avoid costly mistakes.

Top 10 Adjustable Pressure Relief Valves Reviewed

When it comes to managing pressure in various systems, adjustable pressure relief valves are essential tools. These valves help maintain optimal pressure levels, preventing potential system failures. Opening mechanisms can vary, allowing for a tailored pressure setting. This flexibility is invaluable across industries, from manufacturing to HVAC systems.

Before selecting an adjustable pressure relief valve, consider your specific requirements. Identify the pressure range that suits your needs. Improper pressure settings can lead to inefficient operation or damage. Check compatibility with your system’s materials to avoid future problems.

Tips: Always consult installation guidelines closely. A minor mistake in setup can lead to leaks or failure. Regular maintenance is equally crucial; clean the valves periodically to ensure they function correctly. Remember, neglecting routine checks can be costly in the long run, both in repairs and downtime. Choose wisely and stay proactive in maintenance for the best results.

Applications and Benefits of Adjustable Pressure Relief Valves

Adjustable pressure relief valves are crucial in many industrial applications. These valves help maintain desired pressure levels in systems. By automatically releasing excess pressure, they prevent equipment damage. According to a recent industry report, nearly 30% of pressure-related failures involve inadequate pressure relief systems. This statistic emphasizes the need for reliable adjustable valves.

In the oil and gas sector, these valves ensure safe operations. They are also essential in chemical processing, where pressure fluctuations can lead to hazardous situations. The Global Pressure Relief Valve Market is expected to grow at a CAGR of 5.5% between 2023 and 2030. This growth reflects their increasing implementation in various applications.

Despite their benefits, improper maintenance can limit valve performance. Regular inspections are necessary to ensure they function correctly. Inadequate training for personnel can lead to mishandling, which increases risks. Addressing these issues is vital for optimal safety and efficiency in pressure management systems.

Maintenance Tips for Optimal Performance of Pressure Relief Valves

Proper maintenance of adjustable pressure relief valves is crucial for ensuring optimal performance. Regular inspections are necessary. Check for signs of wear, corrosion, or leaks. A valve showing these issues can compromise safety, leading to potential failures. Keep an eye on the valve’s settings. If they drift from the recommended levels, recalibrate immediately. Don’t wait until it’s too late.

Cleaning is another essential step. Dust and debris can accumulate, affecting the valve’s functionality. Use a suitable cleaner and cloth to wipe down the surface regularly. Ensure that components are free of blockages. Over time, seals may degrade. Replace them as needed to maintain a tight seal.

During maintenance, also consider the environment. Vibration and temperature fluctuations can impact valve performance. Document any changes in operating conditions. This is important for future assessments. Adjustments may be necessary if performance issues arise. A proactive approach will ensure longevity and reliability. Remember, neglecting small problems can lead to larger repairs later.

Related Posts

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

How to Choose a Low Pressure Relief Valve for Your System Needs

-

Top 2 Pressure Relief Valve Types You Should Know?