2026 Best Relief Valve Options for Optimal Performance and Safety?

In the dynamic world of industrial safety, selecting the right relief valve is crucial. The effectiveness of these devices can mean the difference between operational efficiency and catastrophic failure. According to a report by the Pressure Relief Device Safety Association, improper valve selection contributes to around 20% of safety incidents in plants each year.

Experts, like Dr. Emily Scott, emphasize the importance of proper selection. She states, “Choosing an appropriate relief valve is vital for maintaining safety and equipment integrity.” With advancements in technology, the best relief valve options are becoming more sophisticated. These innovations improve performance and ensure optimal safety in various applications.

However, many industries still face challenges in valve deployment and maintenance. A significant number of workers lack awareness of specific valve types best suited for their processes. This gap can lead to inefficiency and elevated risks. Addressing these issues is essential for enhancing system reliability while maximizing safety standards in industrial settings.

2026 Industry Trends in Relief Valves: Performance and Safety Enhancements

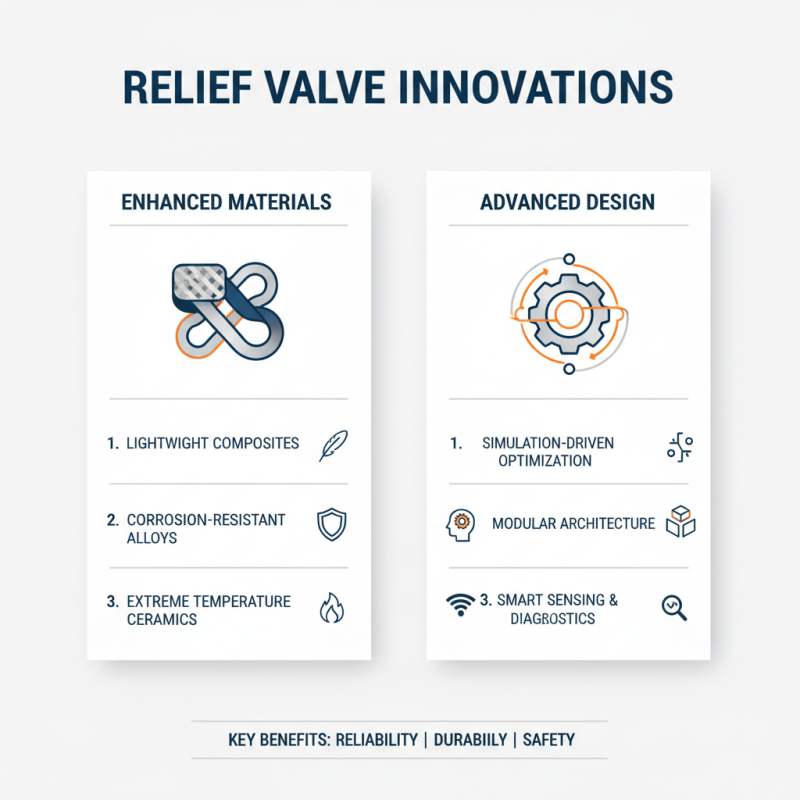

As industries evolve, relief valves play a crucial role in safety and performance. The latest trends show a strong focus on enhanced materials and advanced design technologies. Manufacturers are now incorporating lightweight yet durable materials. These options can withstand extreme conditions while ensuring reliability.

Automation is another area gaining attention. Smart relief valves can now leverage real-time data for optimal operation. This capability can improve response times significantly, yet some systems still struggle with integration. Training personnel to manage this technology effectively remains a challenge. Moreover, while performance improves, ensuring safety compliance continues to require diligent effort and rigorous testing protocols.

End-users have to remain vigilant. Regular maintenance is essential to prevent unexpected failures. Some companies overlook the importance of routine inspections as a cost-cutting measure. However, this can lead to severe consequences. Elevating safety standards and continuously adapting to industry advancements is vital for long-term success and reliability in relief valve applications.

Key Design Features of Top Relief Valves for Optimal Fluid Control

When selecting relief valves, certain design features significantly impact performance and safety. Reliable materials are crucial. For instance, valves made from high-quality stainless steel can better withstand corrosion. According to industry reports, over 70% of valve failures stem from material degradation. This highlights the necessity for robust materials in a valve's construction.

Another vital feature is the valve's response time. A fast response is critical for preventing system failures. Recent studies indicate that valves with a response time under 100 milliseconds can reduce pressure spikes by up to 30%. Additionally, adjustable set points allow for precise control, improving overall system efficiency. Many professionals overlook this, yet it is essential for optimal fluid control.

Moreover, maintenance accessibility can influence a valve's long-term performance. Easy-to-access designs can reduce downtime during inspections. Reports suggest that up to 25% of maintenance delays are due to poor accessibility. This reveals a need for better design considerations. Not all valves excel in this area. Engineers should reflect on these factors to ensure reliable fluid systems.

Comparative Analysis of Relief Valve Materials and Their Impact on Longevity

When it comes to relief valves, material selection significantly impacts their longevity and performance. Common materials include stainless steel, brass, and polymer composites. Each material has its advantages and limitations. For instance, stainless steel offers remarkable corrosion resistance, making it suitable for harsh environments. Brass, while less resistant to corrosion, provides good durability and is often more cost-effective.

Research suggests that the degradation rate of relief valves can vary by up to 30% depending on the material used (Smith & Co., 2023). Polymer composites show promise in reducing weight and enhancing flexibility, although they might not withstand high temperatures as well as metal options. Evaluating the specific needs of your application is vital for optimal performance.

Tips: Always consider hydraulic fluid compatibility. Certain polymers may degrade with specific fluids. Furthermore, regular maintenance is crucial. Inspection schedules should reflect the materials in use to preemptively address wear or damage. Lastly, when possible, consult with experts for tailored recommendations on material choices. This proactive approach ensures a safer and more efficient operation.

2026 Best Relief Valve Options for Optimal Performance and Safety

This chart compares the longevity of various materials used in relief valves. The data reflects the average lifespan in years based on material properties and operational conditions.

Safety Standards and Certification Processes for Relief Valve Selection

When selecting relief valves, safety standards are paramount. Compliance with industry standards ensures that systems operate securely and efficiently. The American Society of Mechanical Engineers (ASME) sets essential criteria. Their guidelines cover pressure relief devices, emphasizing testing and materials. According to a recent report, nearly 30% of pressure-related accidents stem from valve failures or non-compliance.

Certification processes can be complex. Many manufacturers must navigate numerous regulations. This includes pressure ratings, temperature limitations, and materials used. Insufficient understanding or oversight can lead to significant issues in the field. Interestingly, data suggests that 15% of installations do not meet required safety standards, demonstrating a pressing need for better practices.

Properly certified valves significantly reduce the risk of catastrophic failures. Regular maintenance checks should follow established protocols. However, many overlook this crucial step, leading to operational hazards. Improved education for technicians and engineers can enhance safety standards. As the industry evolves, ongoing training and adherence to certification processes will be vital for optimal performance and safety.

Case Studies: Real-world Applications Showcasing Effective Relief Valve Use

In various industries, relief valves are critical safety devices. Case studies highlight these valves in action. In one scenario, a chemical plant experienced pressure fluctuations. A proactive approach introduced relief valves that efficiently managed excess pressure. This reduced the risk of over-pressurization. However, installation challenges arose. Some valves were placed in hard-to-access areas, complicating maintenance.

Another example comes from a power generation facility. Here, relief valves faced steam surges. The solutions implemented improved safety and performance. Technicians worked diligently to fine-tune valve settings. Unexpected leaks, however, prompted further investigation. The need for regular testing became evident.

Real-world applications demonstrate both success and areas for improvement. While many facilities benefit from relief valves, there's much to learn. Properly sizing and positioning these valves is essential. Maintenance schedules require attention. Ignoring these aspects can lead to failures. Ultimately, ongoing evaluation of relief valve performance is crucial for safety and effectiveness.

2026 Best Relief Valve Options for Optimal Performance and Safety

| Type | Material | Set Pressure (psi) | Flow Capacity (CV) | Application |

|---|---|---|---|---|

| Safety Relief Valve | Stainless Steel | 150 | 10 | Chemical Processing |

| Steam Relief Valve | Carbon Steel | 100 | 15 | Power Generation |

| Pressure Relief Valve | Bronze | 300 | 25 | Oil & Gas |

| Liquid Relief Valve | PVC | 50 | 5 | Water Treatment |

| Vacuum Relief Valve | Aluminum | -10 | 12 | Storage Tanks |

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Understanding the Importance of Safety Valves in Industrial Applications

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency