How to Choose the Best Hydraulic Hose for Sale?

Choosing the right hydraulic hose for sale is vital for any industrial operation. A study by MarketsandMarkets indicates that the global hydraulic hose market could reach $2.23 billion by 2026. This signifies the growing reliance on hydraulic systems across various sectors. The right hose ensures efficiency and safety in hydraulic applications.

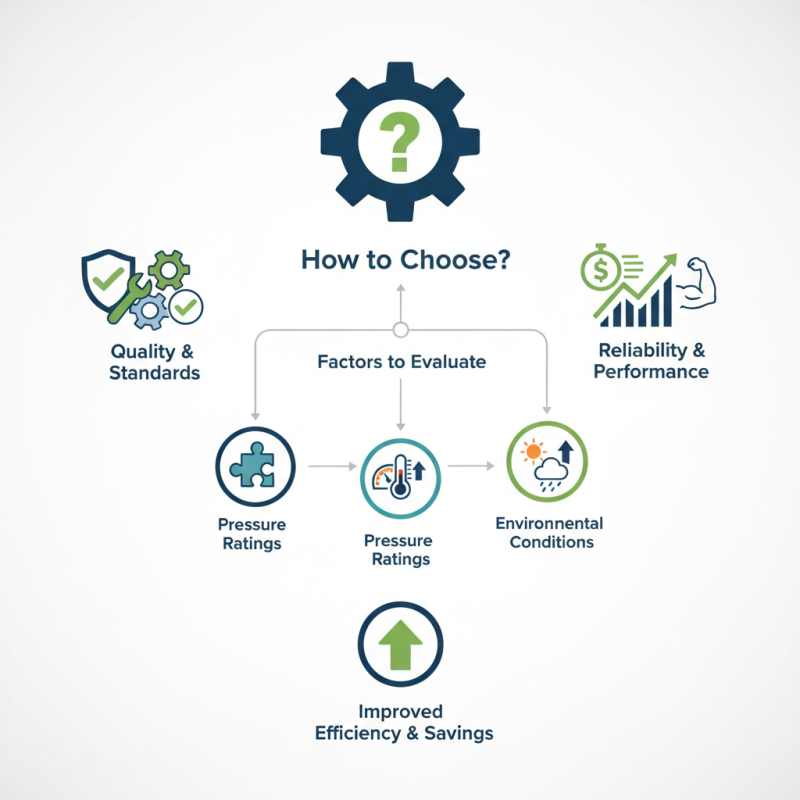

Quality is crucial, but it can be challenging to determine which product stands out. Not all hydraulic hoses meet industry standards. An unsuitable choice might result in system failures or costly downtime. It's essential to evaluate factors like compatibility, pressure ratings, and environmental conditions.

Buying a hydraulic hose is not just about cost. It's also about reliability and performance under pressure. Selecting the best hydraulic hose requires thorough research and a clear understanding of your specific needs. A thoughtful decision can lead to improved operational efficiency and long-term savings.

Understanding Hydraulic Hose Specifications and Standards

When selecting a hydraulic hose, understanding its specifications is crucial. Different applications require hoses with various specifications. The key parameters include working pressure, temperature range, and compatibility with fluids. Working pressure indicates the maximum pressure the hose can handle. A hose that cannot withstand the pressure may burst, leading to failures.

Temperature range is also vital. Hoses must function effectively in various temperatures. If a hose operates outside its rated temperature, it could degrade or lose performance. Compatibility with hydraulic fluids cannot be overlooked. Using the wrong hose may result in chemical reactions, leading to leaks or failures.

Not all hoses are created equal. Sometimes, confusion arises from similar naming conventions. Different industries use varying standards for hoses. Understanding these standards can feel overwhelming. What might suit one application may not be ideal for another. Taking time to research and ask questions is necessary. Testing hoses in specific environments before full-scale use may be wise.

Key Factors Influencing Hydraulic Hose Selection

Choosing the right hydraulic hose involves several key factors. Understanding your specific application helps narrow down options. Consider the fluid type. Different fluids require different materials. This directly impacts the hose's longevity and functionality.

Pressure ratings are essential. Look at the maximum pressure the hose can handle. If it's too low, it may fail. If too high, you may waste money. Also, consider the temperature range. High or low temperatures can degrade materials faster.

Bend radius is another critical aspect. Hoses need to fit into your setup without kinking. Assess the space available. You might need to adjust your design for a proper fit. Finally, don't underestimate the importance of compatibility. Ensure the connectors fit securely. Otherwise, leaks or other issues may arise. Reflect on all these factors before making your choice.

How to Choose the Best Hydraulic Hose for Sale? - Key Factors Influencing Hydraulic Hose Selection

| Factor | Description | Importance |

|---|---|---|

| Operating Pressure | The maximum pressure the hose can withstand. | Critical |

| Temperature Range | The temperature extremes the hose can operate within. | High |

| Compatibility with Fluids | The hose material's resistance to the hydraulic fluid used. | Essential |

| Material | The type of material used in the hose construction. | Important |

| Bend Radius | The minimum radius the hose can be bent without damage. | Moderate |

| Length | The required length needed for the application. | Variable |

Evaluating Hose Materials for Maximum Performance and Durability

When selecting hydraulic hoses, material choice plays a crucial role. Different materials offer various advantages in terms of flexibility, pressure resistance, and temperature tolerance. For instance, synthetic rubber hoses often provide excellent durability and resistance to weathering. However, they may not withstand extreme temperatures as well as thermoplastic hoses. Each option has its strengths and weaknesses, requiring careful consideration based on your needs.

Evaluating the operational environment is essential. For high-pressure applications, reinforced hoses with braided steel or textile layers provide added strength. But using overly robust materials can make handling difficult. Additionally, the chemical compatibility of the hose material with the fluids it will carry is vital. Failure in this aspect could lead to leaks or hose failures, resulting in costly downtime.

Ultimately, a balance between performance and durability must be struck. Testing various materials in real-world conditions can reveal unexpected challenges. Understanding the implications of your choices, such as maintenance needs, extends hose lifespan and performance. It’s a trial-and-error process, leading to smarter, more informed decisions.

Assessing Working Pressure and Temperature Ratings

When selecting a hydraulic hose, understanding working pressure and temperature ratings is crucial. These factors can greatly impact the efficiency and safety of hydraulic systems. Reports indicate that nearly 30% of hydraulic hose failures occur due to improper pressure ratings. Choosing a hose that exceeds the required pressure is often recommended to prevent catastrophic failures.

Temperature ratings are equally important. Many hoses operate within a range of -40°F to +212°F. However, factors like fluid type and environmental conditions can affect the actual performance. A hydraulic hose used in high-temperature environments may need special materials to withstand heat degradation. It's vital to consider surroundings and maintenance practices to avoid unexpected breakdowns.

Miscalculations often occur. Operators might overlook ambient temperatures or changes in operating conditions. For example, a hose may be rated for high pressure, but repeated cycles at elevated temperatures can reduce its lifespan. This disconnect can lead to increased downtime and costly repairs. Understanding these aspects is essential for making informed decisions in hydraulic hose selection.

Common Applications and Their Hydraulic Hose Requirements

When selecting a hydraulic hose, it's crucial to understand specific applications. Different tasks demand different hose types. In construction, for example, hoses face high pressures and abrasions. A strong and durable material is essential. Gutting with proper thickness and tensile strength will ensure safety and performance.

In agricultural settings, flexibility is key. Hoses must withstand bends and twists while transferring fluids. A lightweight option may be favorable, but durability should not be sacrificed. Water and chemical resistance are also significant in these applications. Always consider the environment the hose will operate in.

Unexpected issues can arise if the wrong hose is chosen. Fitting compatibility is often overlooked. Leaks can occur from poor connections, leading to lost productivity. Regular inspection of hoses can prevent failures, yet many neglect this. The right choice saves time and resources in the long run.