How to Choose a Low Pressure Relief Valve for Your System Needs

When it comes to ensuring the safety and efficiency of industrial systems, selecting the right components is crucial. Among these components, the low pressure relief valve plays a pivotal role in safeguarding systems against overpressure conditions. Expert in pressure management, Dr. Jane Hartwell, emphasizes, "A properly selected low pressure relief valve can be the difference between smooth operations and catastrophic failure." Her insights highlight the importance of careful consideration in the selection process.

Choosing a low pressure relief valve involves understanding not only the specific requirements of a system but also the various factors that influence performance and reliability. Factors such as set pressure, flow capacity, and materials of construction must be taken into account to ensure that the valve meets system needs effectively. As industries evolve and technologies advance, the criteria for suitable low pressure relief valves continue to adapt, making it essential for engineers and technicians to stay informed about current best practices and innovations in the field. This guide aims to provide essential insights into the selection process, helping professionals make informed decisions that enhance system safety and efficiency.

Understanding the Function of Low Pressure Relief Valves in Systems

Low pressure relief valves play a critical role in various systems by ensuring safety and maintaining operational efficiency. These valves are designed to open at a predetermined pressure, allowing excess fluid to escape, thereby preventing potential damage to system components. In environments where pressure fluctuations can occur, low pressure relief valves provide a reliable means to regulate output pressure, protecting pipelines, tanks, and other sensitive equipment from overpressure situations.

Understanding the function of low pressure relief valves is essential for effective system design. By preventing pressure build-up, these valves ensure the longevity of the system and its components. They are commonly used in applications such as HVAC systems, process piping, and water treatment facilities, where maintaining a consistent pressure is crucial. When selecting a low pressure relief valve, factors such as the system's pressure range, fluid characteristics, and operational conditions should be carefully considered to ensure optimal performance and reliability. An appropriate valve will not only safeguard the system but also enhance overall efficiency.

Factors to Consider When Choosing a Low Pressure Relief Valve

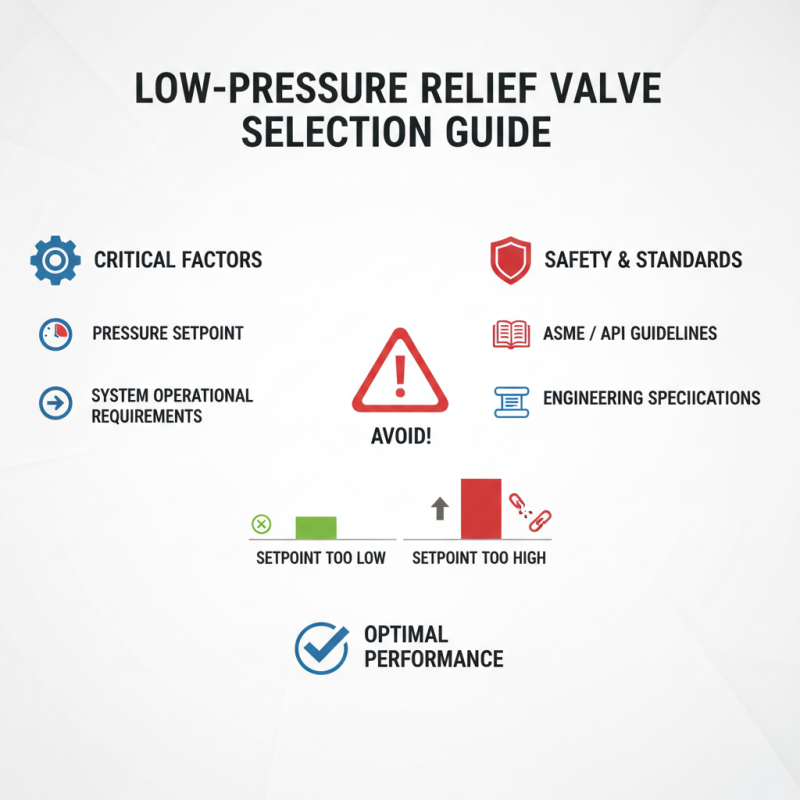

When choosing a low pressure relief valve for your system needs, there are several critical factors to consider to ensure optimal performance and safety. One of the foremost aspects is the pressure set point, which must align with the operational needs of your system. According to industry data, a valve set too high can lead to increased risk of system failures, whereas a set point that is too low may not adequately protect against overpressure conditions. It is essential to consult with engineering specifications and industry standards, such as ASME and API guidelines, which provide clear benchmarks for pressure settings and valve sizing.

Another key consideration is the valve's material compatibility with the fluids it will manage. Depending on the media—be it gases, liquids, or corrosive substances—you must choose materials that will withstand both the operational environment and prevent degradation over time. According to a report from the International Society of Automation, failure to account for material properties can lead to significant maintenance costs and system inefficiencies, with some industries reporting up to 20% in unplanned downtime due to valve failure. Additionally, incorporating features like integrated testing capabilities can enhance reliability and offer a preventive measure against potential operational risks. Properly evaluating these factors can significantly impact the overall safety and efficiency of your system.

Types of Low Pressure Relief Valves and Their Applications

When it comes to low pressure relief valves, understanding the various types and their applications is crucial for selecting the right one for your system. Common types include spring-loaded relief valves, pilot-operated valves, and balanced bellows valves. Spring-loaded relief valves are designed to open at a preset pressure to release excess fluid, making them ideal for applications like water and gas systems. Pilot-operated valves, which utilize a smaller pilot valve to control a larger main valve, are often used in systems requiring high flow rates, as they provide more precise control over pressure release.

Tips: Always consider the media being handled by the valve, as the material compatibility can significantly affect performance and longevity. Ensure that the selected valve can withstand the operational temperature and pressure conditions of your system to prevent premature failures.

Balanced bellows valves offer unique benefits by reducing the effect of back pressure, which can be advantageous in systems with fluctuating pressure levels. They are particularly effective in chemical processing applications where maintaining a stable outlet pressure is key. Each type of valve serves distinct purposes, so assessing your specific needs will lead to better operational efficiency and safety within your system.

Types of Low Pressure Relief Valves and Their Applications

Sizing a Low Pressure Relief Valve for Optimal Performance

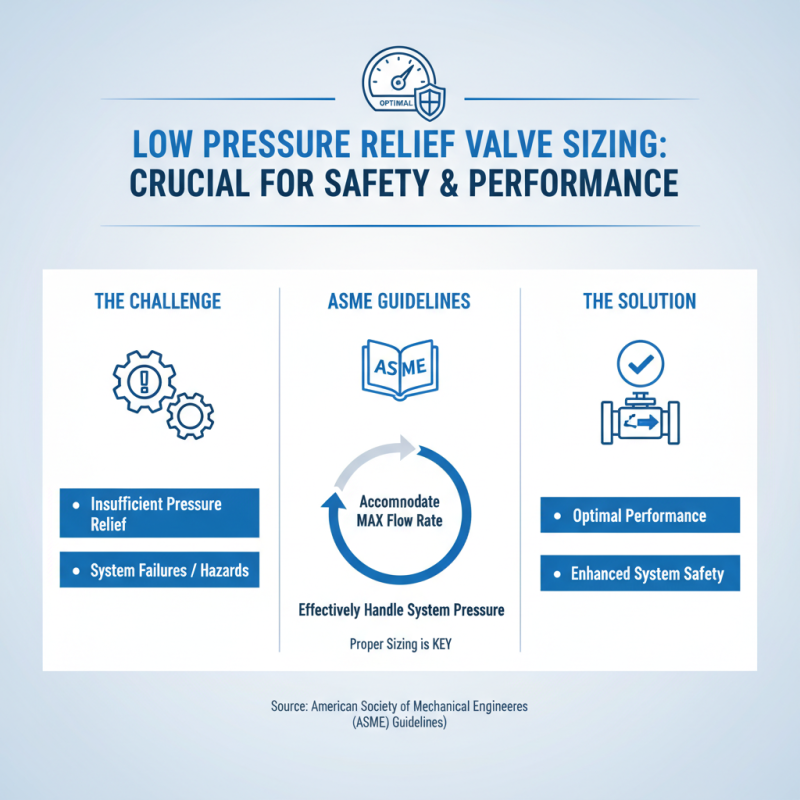

When selecting a low pressure relief valve, proper sizing is crucial for ensuring optimal performance and safety in your system. According to the American Society of Mechanical Engineers (ASME) guidelines, a valve must be sized to accommodate the maximum expected flow rate while handling the system pressure effectively. An improperly sized valve may lead to inadequate pressure relief, resulting in potential system failures or hazardous situations.

The sizing process typically involves calculating the set pressure and the flow capacity required. Industry reports indicate that utilizing flow equations can help determine the appropriate size. For instance, the National Institute for Standards and Technology (NIST) provides a set of methodologies that take into account factors such as the critical pressure ratio and the discharge coefficient, which can greatly influence the performance of a low pressure relief valve. As a general rule, relief valves should be sized to provide a margin of safety above the maximum expected pressure to prevent undesirable system conditions and ensure compliance with safety standards.

Furthermore, it is essential to consider the specific application and environmental conditions when sizing a relief valve. Data from the Process Industry Practices (PIP) suggests that factors like temperature, density, and fluid characteristics play significant roles in the valve's sizing and efficiency. By meticulously evaluating these parameters, engineers can select a low pressure relief valve that not only meets regulatory requirements but also enhances the reliability and longevity of the system. Proper sizing, therefore, is a critical step in maintaining operational integrity and minimizing risk.

Installation and Maintenance Tips for Low Pressure Relief Valves

When it comes to installing low pressure relief valves, the first step is to ensure proper orientation and placement within the system. These valves should be installed in a vertical position whenever possible, allowing gravity to assist in their operation. It’s crucial to choose a location that is easily accessible for future maintenance without compromising the efficiency of the system. Additionally, make sure to install the valve at a point in the system where pressure build-up is most likely to occur, typically close to the source of pressure generation.

Maintenance is vital for keeping low pressure relief valves functioning effectively. Regular inspections should be scheduled to check for any signs of wear, corrosion, or debris that could hinder performance. It’s recommended to forcefully operate the valve periodically to verify that it opens and closes properly, ensuring it will perform when needed. Lubrication of moving parts should be done with care, as excessive lubrication can attract contaminants. Lastly, maintaining records of all inspections and maintenance activities will help in tracking performance and predicting future needs effectively.

Related Posts

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

10 Essential Tips for Choosing the Right Pressure Release Valve

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips