How to Choose the Right Pressure Relief Valve for Your Needs?

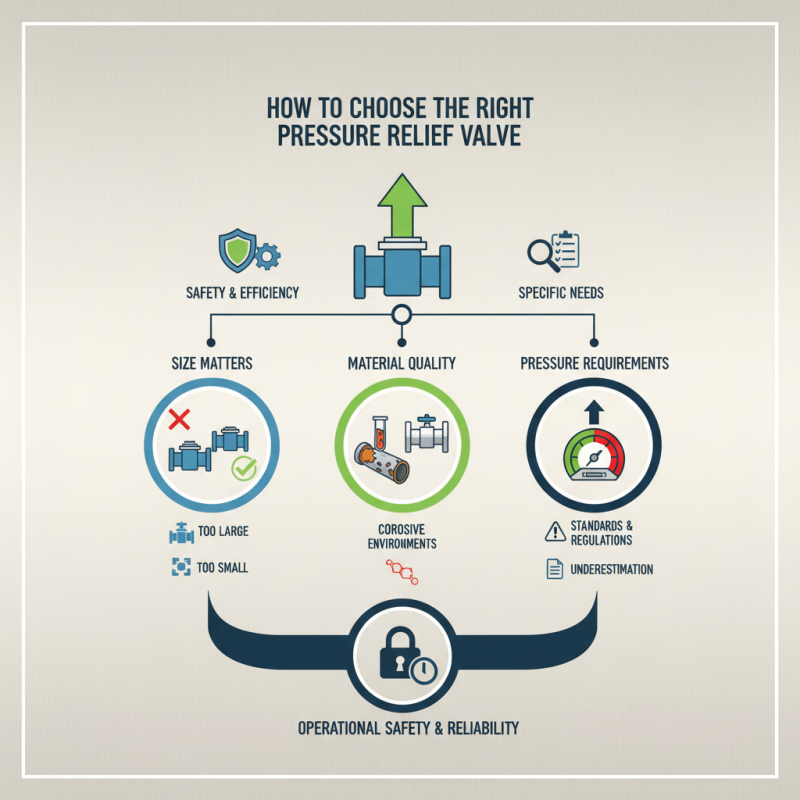

Choosing the right pressure relief valve is crucial for safety and efficiency. Experts emphasize the importance of understanding your specific needs. John Smith, a leading expert in the 2 pressure relief valve industry, once said, “Selecting the right valve can save time and prevent costly failures.”

Many users overlook details. For instance, not every situation requires the same specifications. A valve might be too large or too small for your needs. This misstep can lead to inefficiencies. Additionally, consider the material quality. Corrosive environments need valves made from resistant materials.

Understanding pressure requirements is also vital. Some people may underestimate the pressure limits. This lack of knowledge can result in improper installations. Always ensure that you are informed about standards and regulations. The right 2 pressure relief valve is essential for operational safety and reliability.

Understanding Pressure Relief Valve Types and Functionality

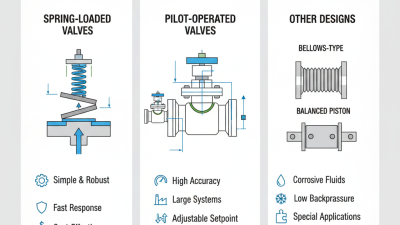

When selecting a pressure relief valve, understanding the types and how they function is crucial. There are various types, including spring-loaded, pilot-operated, and rupture disk valves. Spring-loaded valves are the most common. They work by using a spring to hold back pressure. When the pressure exceeds a set limit, the valve opens. This type is simple and effective. However, it may not be suitable for high-pressure situations.

Pilot-operated valves are designed for more precise control. They can handle larger flows and higher pressures. Their complexity can be a double-edged sword. While they offer better performance, maintenance may be challenging. Rupture disks are another option. These are designed to fail at a specific pressure point. They are quick and reliable, but once activated, they require replacement. This leads to downtime that can be costly.

Each valve type has its pros and cons. It’s essential to assess your needs carefully. Choosing a valve without proper understanding can lead to costly errors. Always consider your operational environment and the specific characteristics of the system. This can make a significant difference. Take the time to reflect on your choices. Finding the right match can enhance safety and efficiency.

How to Choose the Right Pressure Relief Valve for Your Needs?

| Valve Type | Functionality | Common Applications | Set Pressure Range (psi) | Material |

|---|---|---|---|---|

| Spring-Loaded | Opens at a predetermined pressure to relieve pressure buildup | Boiler systems, hydraulic systems | 30 - 1500 | Steel, stainless steel |

| Pilot-Operated | Uses a pilot valve to control pressure relief | Chemical processing, gas systems | 50 - 4500 | Aluminum, brass |

| Balanced Bellows | Minimizes the effect of backpressure on set pressure | Refinery, oil and gas | 10 - 3000 | Carbon steel, stainless steel |

| Dead Weight | Relieves pressure by using weights to counteract pressure | Calibration of instruments, laboratory applications | 5 - 100 | Brass, alloy |

Identifying Key Specifications for Your Application Needs

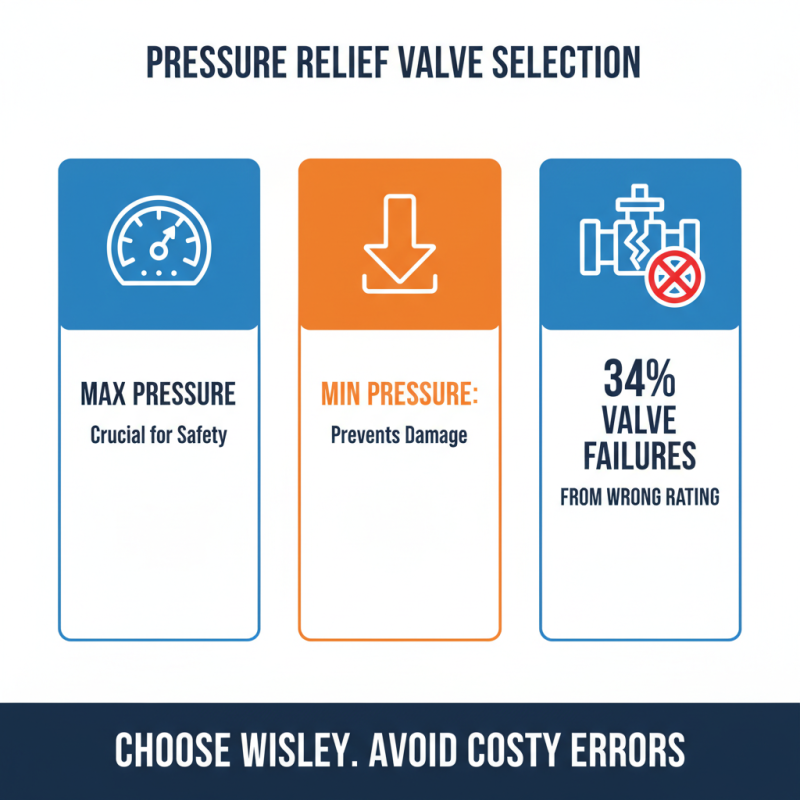

Choosing the right pressure relief valve is crucial for many industries. One of the key specifications to analyze is the pressure rating. According to industry studies, about 34% of valve failures stem from incorrect ratings. Understanding the maximum and minimum pressure is essential. This ensures safety and efficiency in operations. A mismatch can lead to serious accidents or damages, which are costly both financially and operationally.

Another critical aspect to consider is the flow capacity. A pressure relief valve must handle the expected flow conditions. Typically, valves are rated by their flow coefficient (Cv). Research shows that valves with inadequate flow capacity can cause extensive damage during fluid release. Operators should analyze system requirements carefully. This includes examining pipe sizes and upstream conditions. Mistakes often arise from assumptions rather than calculated needs.

Material selection also matters significantly. The valve material must withstand the application’s environment. For example, corrosive liquids require specific materials. Many industries report failures due to corrosion-related issues, impacting productivity. A valve that rusts or degrades can lead to leaks. This is especially concerning in chemical processing industries. Making informed choices here can help avoid unforeseen costs and downtime.

Evaluating Safety Standards and Regulatory Compliance Requirements

When selecting a pressure relief valve, understanding safety standards is crucial. Various organizations set these regulations to ensure comprehensive safety across industries. For instance, the American Society of Mechanical Engineers (ASME) provides stringent guidelines. Their standards aim for reliability and safety in pressure relief systems.

Moreover, compliance with standards like the Pressure Equipment Directive (PED) in Europe is essential. In fact, a report from the International Association of Oil and Gas Producers reveals that adhering to these standards can reduce incidents by up to 30%. Operators should not overlook these compliance aspects, as they directly impact the overall safety of operations.

Evaluating valves against these benchmarks is vital. Sometimes, organizations assume that meeting basic criteria is enough. However, deeper analysis often uncovers hidden risks. Regular audits and updates to safety practices can significantly enhance reliability. Industry reports highlight that ongoing education about compliance can aid in maintaining these standards.

Assessing Installation and Maintenance Considerations

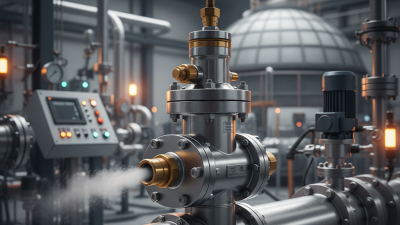

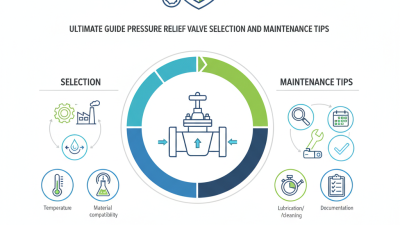

When choosing a pressure relief valve, installation and maintenance are crucial factors. Ensure the valve fits your system correctly. Measure pipe size and pressure specifications accurately. An inappropriate fit could lead to leaks or system failures. Consider the location of the valve. Access for maintenance is essential.

Regular maintenance checks help avoid costly breakdowns. Inspect the valve periodically for signs of wear. If you notice any irregularities, replace parts promptly. Ignoring minor issues could lead to major complications later. Understanding your system's environment also plays a role. High temperatures or corrosive substances can affect valve performance.

Documentation is key to effective maintenance. Keep records of installations and maintenance activities. This helps track valve performance over time. Reflecting on previous decisions can improve future choices. The right balance between accessibility and performance is vital for optimal operation.

Comparing Cost and Performance of Different Valve Brands

When selecting a pressure relief valve, comparing cost and performance is key. Different brands often offer a range of features. Some valves may be priced lower but fail to perform adequately under high pressure. This can lead to costly system failures.

Performance can vary widely. Some valves are made with advanced materials, enhancing their durability. Others may work well but have a shorter lifespan. Inspecting the specifications can reveal these differences. Look for details such as flow rate and response time. These factors directly affect efficiency.

Price alone should not dictate your choice. Investing in a more reliable valve can save money in the long run. However, it's essential to evaluate your actual needs. Sometimes, a less expensive option might suffice. Understanding your system's requirements is crucial.

Comparing Cost and Performance of Different Pressure Relief Valves

This chart compares the cost and performance of different pressure relief valves based on their price and pressure relief rate. The data represents a selection of generic pressure relief valves, allowing users to evaluate their options effectively.

Related Posts

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips