Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

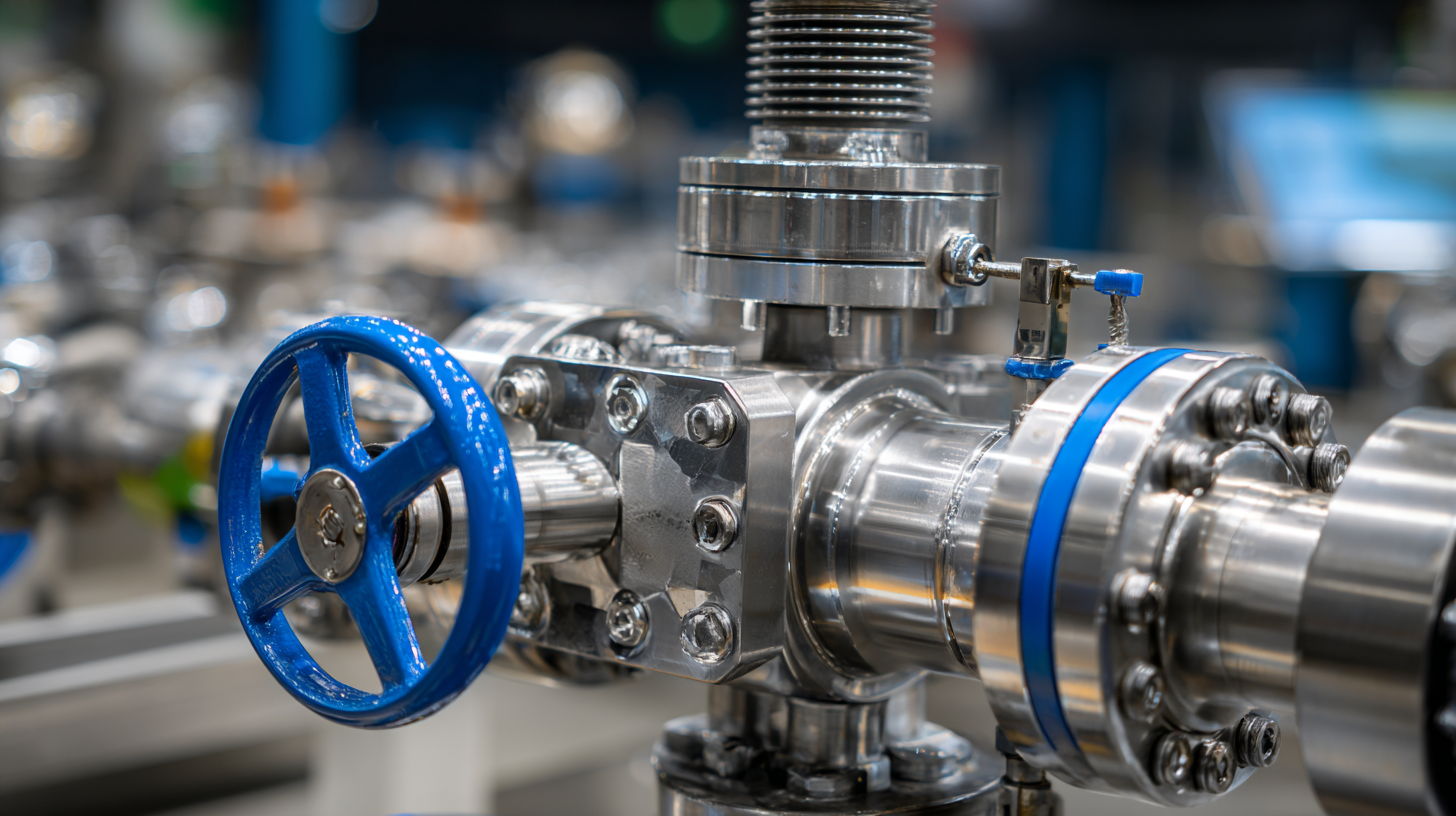

In today's rapidly evolving industrial landscape, the demand for enhanced operational efficiency and sustainability has never been more critical. Consolidated valves have emerged as indispensable components in various applications, contributing significantly to optimizing performance and reducing waste.

According to a recent report from the Industrial Valve Market, the global valve market is expected to reach $122 billion by 2026, with consolidated valves playing a pivotal role in this growth due to their ability to provide reliable control and regulation of fluids.

The efficiency gains offered by these valves are especially evident in sectors such as oil and gas, power generation, and water treatment, where precise flow management can lead to substantial cost savings and improved safety. By leveraging advanced materials and innovative designs, consolidated valves not only meet the demands of modern industry but also support sustainability goals by minimizing leaks and energy consumption. As industries continue to innovate and seek higher efficiency levels, the importance of consolidated valves will undoubtedly become even more pronounced.

The efficiency gains offered by these valves are especially evident in sectors such as oil and gas, power generation, and water treatment, where precise flow management can lead to substantial cost savings and improved safety. By leveraging advanced materials and innovative designs, consolidated valves not only meet the demands of modern industry but also support sustainability goals by minimizing leaks and energy consumption. As industries continue to innovate and seek higher efficiency levels, the importance of consolidated valves will undoubtedly become even more pronounced.

The Importance of Consolidated Valves in Streamlining Operations

In modern industrial applications, consolidated valves have emerged as critical components in streamlining operations. These valves, which combine various functionalities into a single device, significantly reduce the complexity and cost associated with multiple valve systems. According to a report by the Global Valve Market Research Institute, industries utilizing consolidated valves have reported a 30% reduction in installation and maintenance costs, highlighting their efficiency.

Furthermore, consolidated valves improve operational reliability and safety. A study published in the Journal of Industrial Efficiency found that companies implementing these valves noted a decrease in operational downtime by up to 25%. This reduction is primarily due to the minimized risk of leaks and mechanical failures, which are often associated with traditional valve systems. By adopting consolidated valves, industries can not only enhance their process efficiency but also ensure a safer working environment, ultimately leading to greater productivity and profitability.

Evaluating Cost Savings Through the Use of Consolidated Valves

In modern industrial applications, the implementation of consolidated valves has emerged as a key strategy for achieving significant cost savings. According to a report by the Global Valve Market Research Institute, industries can reduce operational costs by up to 25% when utilizing these specialized valves. By streamlining fluid control processes and minimizing energy consumption, consolidated valves enable facilities to run more efficiently while also decreasing maintenance and replacement expenses.

Moreover, the durability and reliability of consolidated valves contribute to their cost-saving potential. A study published by the Industrial Applications Journal noted that companies that transitioned to consolidated valves experienced a 30% reduction in valve failure rates. This decline not only translates into lower maintenance costs but also enhances overall system uptime. With the ability to handle various pressure levels and flow rates, consolidated valves offer a versatile solution that can adapt to different operational needs without compromising performance or safety.

Enhancing Safety and Reliability in Industrial Processes with Consolidated Valves

In the realm of modern industrial applications, the significance of consolidated valves cannot be overstated, particularly in enhancing safety and reliability within critical processes. The global high-purity valve market is projected to reach $2.26 billion by 2024 and is expected to grow to $3.45 billion by 2033, reflecting a CAGR of 4.81% during the forecast period. These specialized valves ensure the integrity of systems handling food, beverages, and pharmaceuticals, where the purity is paramount. Their ability to maintain strict compliance with health and safety regulations makes them indispensable in industries that prioritize quality and safety.

Similarly, the bronze gate valve market presents promising growth, with a market valuation of $150 million in 2022 and an anticipated growth to $230 million by 2030, indicating a CAGR of 5.5% from 2024 to 2030. As industries increasingly focus on reliable infrastructure to support their operations, the demand for robust and efficient valve solutions like bronze gate valves continues to rise. This trend highlights the evolving landscape of industrial applications, where operational efficiency and safety are now more critical than ever.

Innovative Technologies Driving the Evolution of Consolidated Valves

The industrial sector is witnessing a transformative shift with the adoption of innovative technologies that drive the evolution of consolidated valves. According to a report by MarketsandMarkets, the global industrial valve market is projected to reach $98.5 billion by 2025, growing at a CAGR of 4.2%. This growth is fueled by advancements in automation, digitalization, and materials science, making consolidated valves more efficient and reliable in modern applications.

One significant innovation is the integration of IoT (Internet of Things) sensors in consolidated valves, allowing for real-time monitoring and predictive maintenance. This technology enhances operational efficiency by reducing downtime and maintenance costs, as demonstrated by a study from Deloitte, which reports that organizations implementing IoT solutions in valve management have seen a reduction in operational costs by up to 20%. Furthermore, the introduction of advanced materials and coatings improves the performance of consolidated valves under extreme conditions, thereby expanding their applicability across various industries, including oil and gas, chemical processing, and power generation. This paradigm shift represents not just an enhancement in functionality but a fundamental rethinking of how consolidated valves contribute to industrial efficiency.

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

| Application Area | Valve Type | Material | Size Range (inches) | Pressure Rating (psi) | Temperature Range (°F) | Innovative Features |

|---|---|---|---|---|---|---|

| Oil & Gas | Ball Valve | Stainless Steel | 1 - 12 | 1500 | -20 to 350 | Automated Actuation |

| Water Treatment | Gate Valve | Ductile Iron | 6 - 24 | 300 | 32 to 150 | Corrosion Resistance |

| Energy Generation | Globe Valve | Carbon Steel | 2 - 10 | 600 | -10 to 1200 | High Efficiency Flow Control |

| Chemical Processing | Check Valve | PVC | 1 - 6 | 150 | -10 to 180 | Lightweight Design |

| Pharmaceutical | Pinch Valve | Silicone | ½ - 4 | 100 | 50 to 250 | Sterile Flow Control |

Case Studies: Successful Implementation of Consolidated Valves in Various Industries

The implementation of consolidated valves across various industries has showcased significant efficiency gains and operational improvements. For instance, a recent report by the International Society of Automation indicates that industries utilizing these valves have experienced a reduction in energy consumption by up to 20%, attributing this to optimized fluid control and minimized leakages. In the oil and gas sector, case studies have revealed that the integration of consolidated valves has led to enhanced safety measures, reducing risks associated with pressure fluctuations and potential leaks, which in turn can save companies millions in operational costs.

In the chemical manufacturing industry, a leading firm reported a 30% decrease in downtime after integrating consolidated valves into their production lines. According to a study by Research and Markets, adopting such technology can enhance process reliability, providing a pivotal advantage in competitive markets. Additionally, consolidating valve systems has been found to streamline maintenance procedures, as validated by field trials that demonstrate a 25% improvement in maintenance turnaround times. These case studies emphasize the transformative impact of consolidated valves, illustrating their essential role in driving efficiency and safety across modern industrial applications.

Related Posts

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications