10 Essential Tips for Choosing the Right Pressure Release Valve

In the complex world of industrial safety and process engineering, choosing the right pressure release valve (PRV) is a critical decision that can significantly impact operational safety and efficiency. According to a recent report by the International Society of Automation (ISA), improper pressure release valve selection accounts for approximately 30% of mechanical failures in process industries, leading to costly downtimes and safety incidents. As industries strive for greater efficiency and safety, understanding the fundamental aspects of PRVs becomes essential.

Expert opinions echo this sentiment. John Smith, a renowned engineer with over 20 years of experience in pressure systems, emphasizes, "The right pressure release valve not only ensures compliance with safety standards but also enhances the reliability of the entire system." His insights highlight the importance of considering factors such as system pressure, media compatibility, and regulatory requirements when selecting a PRV. By adhering to best practices in the selection process, organizations can mitigate risks and safeguard their operations, ensuring a more resilient industrial environment.

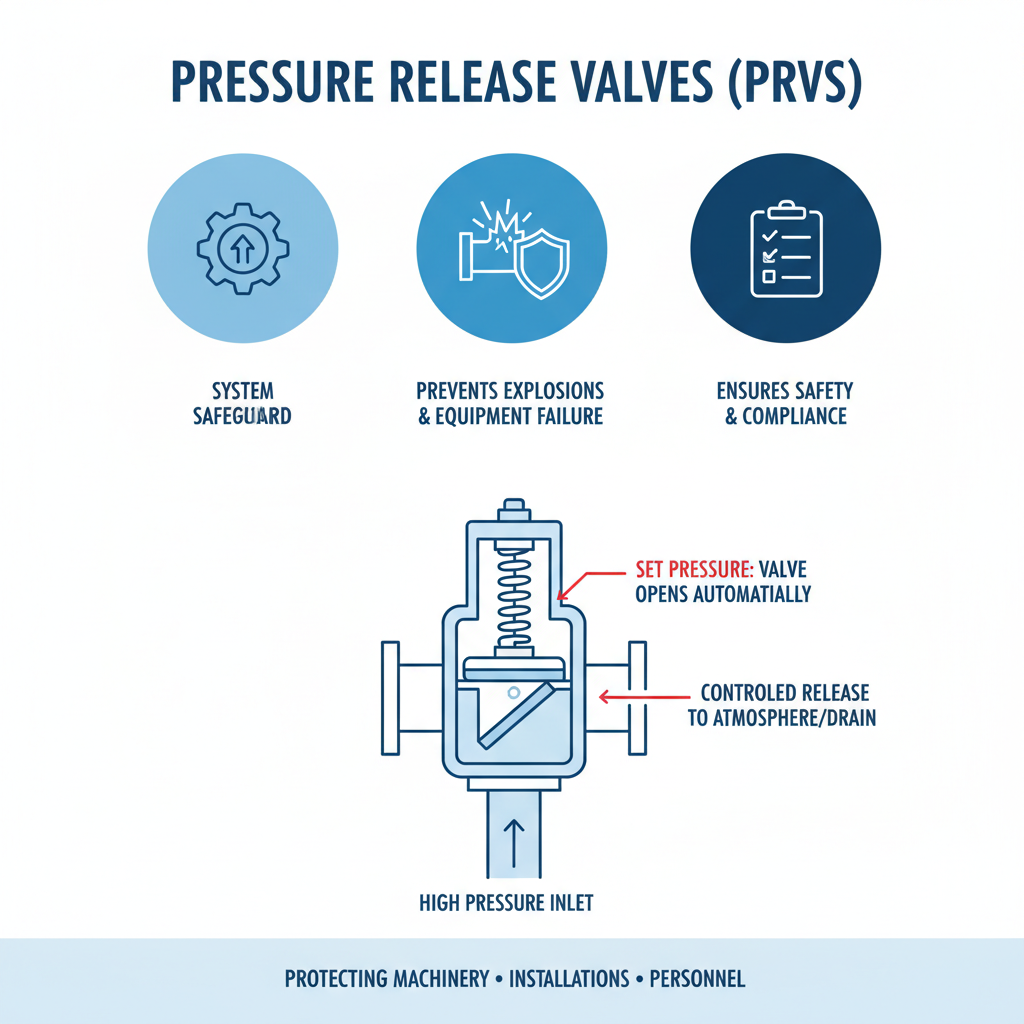

Understanding the Functionality of Pressure Release Valves

Pressure release valves (PRVs) play a crucial role in safeguarding systems from excessive pressure build-up by allowing controlled release. Understanding the functionality of these valves is vital when selecting the right one for your needs. Typically, a PRV is designed to open automatically at a predetermined pressure to prevent potential hazards like explosions or equipment failure. This functionality not only protects machinery and installations but also ensures compliance with safety standards.

When evaluating a pressure release valve, consider its set pressure, flow capacity, and material compatibility. The set pressure dictates when the valve will activate; hence, accurate calibration is essential. Additionally, the flow capacity should align with your system's requirements to prevent pressure surges that can lead to failures. The material of the valve must be compatible with the fluids or gases involved, ensuring durability and reliability. Recognizing these factors contributes to informed decisions, leading to optimal performance and enhanced safety in your operations.

Identifying the Appropriate Size and Pressure Rating Needed

When selecting a pressure release valve, determining the appropriate size and pressure rating is crucial to ensure safety and efficiency in your system. The size of the valve must match the requirements of the application it serves; if the valve is too small, it may not vent the necessary pressure, while an oversized valve can lead to operational inefficiencies. Consider consulting flow data and system specifications to identify the correct dimensions for your application.

Equally important is the pressure rating of the valve. This rating indicates the maximum pressure that the valve can safely handle before it opens to relieve excess pressure. When choosing a valve, always select one with a pressure rating that exceeds the maximum expected pressure of your system. Remember, a margin for safety is essential to prevent accidents and equipment damage.

Additionally, keep in mind that environmental conditions may affect your selection. High temperatures, corrosive substances, or particulate-laden environments can all impact valve performance. Always account for these factors while analyzing your needs. Choosing the right pressure release valve not only protects your equipment but also ensures optimal performance in your operations.

10 Essential Tips for Choosing the Right Pressure Release Valve

| Tip No. | Tip Description | Size Consideration | Pressure Rating (PSI) | Material Options |

|---|---|---|---|---|

| 1 | Determine the application requirements. | Choose size based on flow requirements. | Up to 150 PSI | Brass, Stainless Steel |

| 2 | Select the right pressure setting. | Consider system maximum pressure. | 150 - 300 PSI | Plastic, Aluminum |

| 3 | Evaluate the environment. | Size dictated by installation space. | 300 - 600 PSI | Bronze, Carbon Steel |

| 4 | Consider the fluid type. | Match size with pipe dimensions. | 600 - 1000 PSI | Polymer, PVC |

| 5 | Check codes and regulations. | Size may vary by jurisdiction. | Above 1000 PSI | Custom alloys, High-grade Steel |

| 6 | Analyze historical performance data. | Size based on past failures. | Varied, based on requirement | Stainless Steel, Titanium |

| 7 | Consult with industry experts. | Expert recommendation on size. | Every application has a unique pressure need. | Nickel Alloys, Ceramics |

| 8 | Review compatibility with existing equipment. | Size to align with current fittings. | Portable vs Fixed pressures | Aluminum, Cast Iron |

| 9 | Investigate installation requirements. | Size must fit mounting space. | Check localized PSI needs. | Composite materials, Hybrid designs |

| 10 | Validate the warranty and support. | Sizing may impact service agreements. | Warranty specs on full range of pressures. | Standard materials vs Upgraded options |

Material Selection: Choosing the Right Composition for Durability

When selecting a pressure release valve, material selection is a crucial factor that significantly impacts its durability and performance. Common materials used in the construction of these valves include stainless steel, brass, and plastic. Stainless steel is often preferred for its resistance to corrosion and high temperatures, making it suitable for applications in industries such as petrochemical and pharmaceutical. On the other hand, brass offers a balance between strength and cost-effectiveness, making it a popular choice for less demanding environments.

Additionally, the chemical compatibility of the valve material with the fluids being handled cannot be overlooked. Using materials that resist interaction with the process fluids ensures not only the longevity of the valve but also the safety of the system. For instance, if the valve will be exposed to corrosive substances, opting for a material with suitable chemical resistance is essential to prevent failures and costly downtime. Ultimately, understanding the specific operational conditions and selecting the right material accordingly will lead to the optimal performance of the pressure release valve over time.

Choosing the Right Pressure Release Valve Material

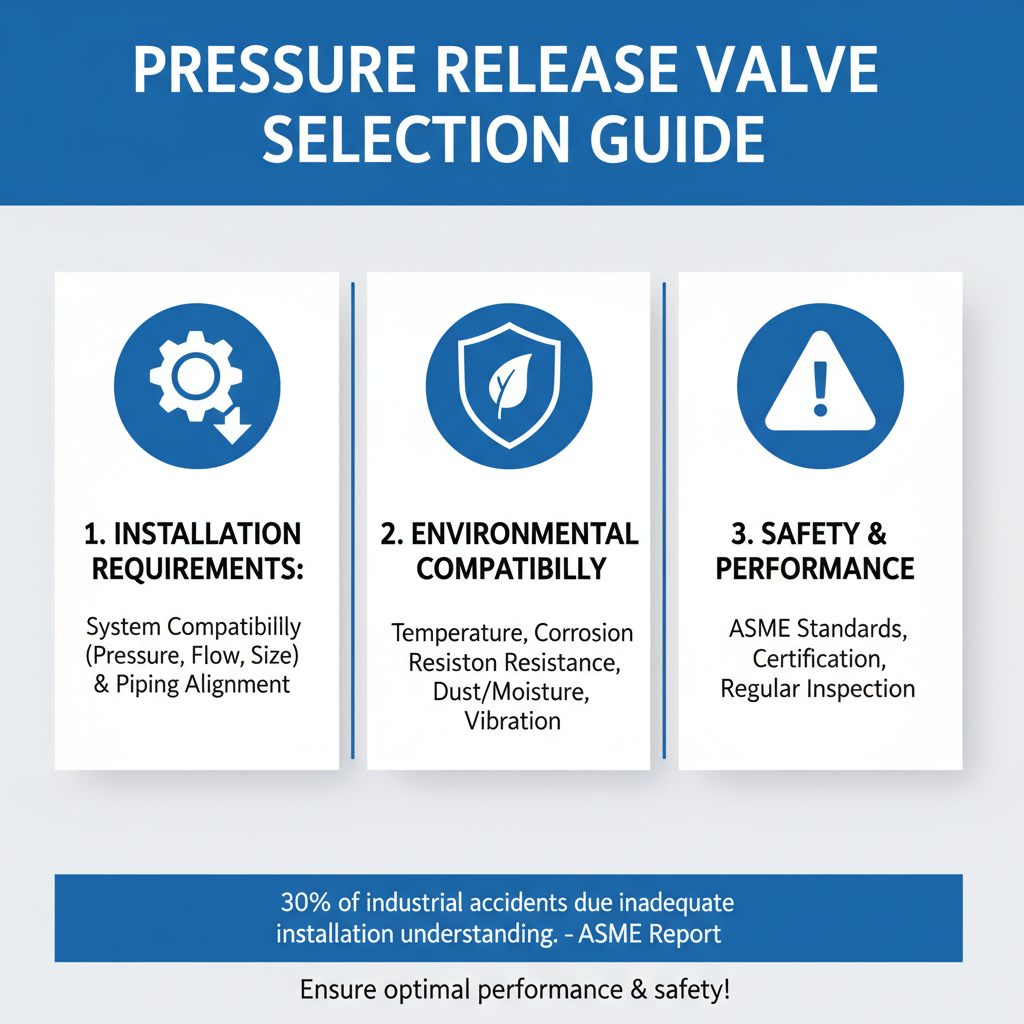

Evaluating Installation Requirements and Environment Compatibility

When selecting a pressure release valve, it's crucial to consider installation requirements and environmental compatibility to ensure optimal performance and safety. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of industrial accidents can be attributed to inadequate understanding of installation guidelines. This emphasizes the importance of aligning the valve's specifications with the unique conditions of your system and location.

Tip: Always verify the pressure range and temperature limits of the valve. A reputable study from the Oil and Gas Journal indicates that improper pressure ratings can lead to system failures, highlighting that 25% of such failures occur due to mismatched specifications. Understanding the environment in which the valve will operate—such as exposure to corrosive substances or extreme temperature variations—is essential in choosing a reliable component.

Additionally, consider the valve's compatibility with surrounding equipment. A recent survey indicated that nearly 40% of maintenance issues arise from compatibility problems, underscoring the necessity of thorough evaluation before installation. Tip: Consult with manufacturers about material choices and certifications to ensure the valve can withstand local conditions and service demands, reinforcing the need for meticulous planning and informed decision-making in selecting pressure release valves.

Budgeting Considerations: Balancing Cost and Quality in Selection

When selecting a pressure release valve, budgeting considerations play a critical role in ensuring a balance between cost and quality. According to a report by the Engineering News-Record, a prudent budget for industrial equipment can range from 1% to 5% of a project's total cost. This highlights the importance of not compromising on quality due to budget constraints. A low-cost valve may seem appealing, but investing in a high-quality valve reduces the risk of system failures, which can lead to significant financial losses and safety hazards.

Tip 1: Evaluate the total lifecycle cost of the valve, including maintenance and replacement costs. A valve might be cheaper upfront, but if it wears out quickly, the eventual replacement expenses could far exceed initial savings.

Tip 2: Look for valves that offer warranties or service contracts. Products from reputable manufacturers often come with guarantees that can provide additional value over the long term. According to the American Society of Mechanical Engineers, a quality pressure release valve can ensure that operational efficiency remains high, ultimately justifying a higher initial investment with improved safety and performance.

By carefully considering these budgeting aspects, you can make an informed decision that balances cost-effectiveness with reliability and functionality.

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023