Essential Tips for Choosing a Safety Relief Valve?

Choosing the right safety relief valve is critical in ensuring system safety and performance. A recent industry report highlighted that improperly selected valves can lead to significant system failures. These failures often result in costly downtime and potential hazards. In the United States alone, over 40% of industrial accidents are linked to inadequate safety mechanisms.

When selecting a safety relief valve, one must consider various factors. The valve's capacity, material compatibility, and set pressure are vital. Many engineers overlook these details, assuming all valves are equivalent. However, a mismatched valve can exacerbate pressure fluctuations, leading to severe operational risks.

Proper training and understanding are crucial. Over 60% of engineers have cited knowledge gaps in valve performance specifications. Such gaps can make a tangible difference in safety outcomes. The right safety relief valve can mitigate these risks significantly and enhance overall safety in industrial processes.

Types of Safety Relief Valves and Their Applications

When selecting a safety relief valve, understanding the types available is crucial. There are two primary categories: pressure relief valves and vacuum relief valves. Pressure relief valves help prevent excessive pressure in systems like boilers. They release gas or liquid when the pressure exceeds a set limit. Vacuum relief valves work differently. They allow air into a system to prevent a vacuum that could cause damage.

Applications vary significantly. In the oil and gas industry, pressure relief valves are critical. They ensure systems operate safely under high pressures. In chemical plants, these valves protect against catastrophic failures. Vacuum relief valves, on the other hand, are vital in storage tanks. They maintain stable pressure while optimizing process efficiency.

It's essential to consider installation environment too. Factors such as temperature, fluid type, and installation orientation affect valve performance. The wrong choice can lead to leaks or failures. Be mindful of manufacturers' guidelines yet remember that not every option is perfect. Rethink common misconceptions about safety relief valves before making a decision. This reflection can lead to smarter choices.

Key Factors to Consider When Selecting a Safety Relief Valve

Choosing a safety relief valve requires attention to various key factors. First, you need to assess the operating pressure and temperature of your system. Make sure the valve can handle the maximum pressure. Consider the material of the valve as well. It should be compatible with the fluid it will protect against.

Another crucial factor is the valve size. A valve that is too small may not release enough pressure in an emergency. Conversely, an oversized valve could lead to inefficient operation. You must also think about the installation environment. Will it face extreme temperatures or corrosive substances? Such elements can affect performance and longevity.

Finally, look for a valve with a reliable design. Complex mechanisms can fail unexpectedly. Simplicity often leads to better reliability. Keep in mind, feedback from users is valuable. Their experiences may highlight potential issues you hadn’t considered. Evaluating such details ensures a better decision in the long run.

Essential Tips for Choosing a Safety Relief Valve

This chart illustrates the key factors to consider when selecting a safety relief valve, rated on a scale from 1 to 10 based on their importance. Material compatibility is the most critical factor, followed closely by pressure and temperature ratings.

Understanding Pressure Settings and Performance Ratings

When selecting a safety relief valve, understanding pressure settings is crucial. The pressure setting determines when the valve opens to relieve excess pressure. Accurate settings ensure optimal performance and safety. An incorrect pressure level can lead to ineffective operation. It might cause excessive pressure in the system, risking equipment failure.

Performance ratings also play a significant role. They reflect the valve's ability to handle specific flow rates. For different applications, the right performance rating is essential. A valve that exceeds or underperforms can have dire consequences. It's also vital to consider the medium being handled. Different fluids and gases can affect the valve's longevity and reliability.

In addition to these factors, installation and maintenance are often overlooked. A poorly installed valve can lead to serious accidents. Regular checks are necessary but often neglected. Understanding these details can prevent significant issues down the line. Making the right choice is not always straightforward, and oversights can happen. Understanding the basics is key, but continuous learning is essential.

Essential Tips for Choosing a Safety Relief Valve

| Criteria | Description | Example Data |

|---|---|---|

| Pressure Settings | The pressure at which the valve is designed to open to relieve excess pressure. | 100 psi |

| Material | The material used for the valve affects durability and compatibility with various fluids. | Stainless Steel |

| Performance Ratings | How well the valve performs under specified conditions, including flow capacity and response time. | API Standard 527 |

| Size | The valve size should be compatible with your system to ensure proper flow rates. | 1 inch |

| Certifications | Validations and certifications ensure that the valve meets industry regulations and safety standards. | ASME Section VIII |

Materials and Design Considerations for Durability and Reliability

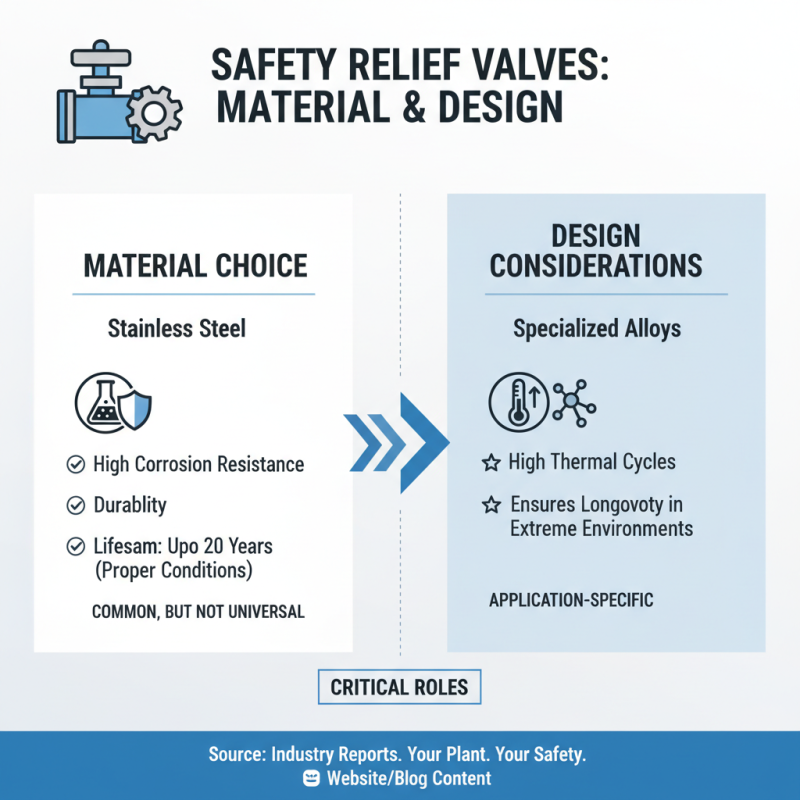

When selecting a safety relief valve, material choice and design play critical roles. A common material used is stainless steel. It offers high corrosion resistance and durability. According to industry reports, valves made from such materials can last up to 20 years under proper conditions. However, not all applications may benefit from stainless steel. For instance, environments with high thermal cycles may require specialized alloys to ensure longevity.

Design is another factor that affects reliability. A well-designed valve must cope with pressure fluctuations effectively. Reports indicate that improper designs can lead to failure rates as high as 25%. Thoughtful design reduces this risk. An appropriate valve sizing, based on actual flow conditions, is crucial. Too small or oversized valves can both lead to issues, such as premature wear or ineffective pressure control.

Additionally, maintenance practices are essential. Regular check-ups help prevent failures. Ignoring routine maintenance can lead to costly downtimes. Data suggest that 40% of valve failures result from lack of upkeep. Exploring innovative designs and robust materials may help to mitigate such problems. Durability needs to be balanced with operational efficiency, inviting further reflection on existing solutions in this challenging environment.

Regulatory Standards and Compliance for Safety Relief Valves

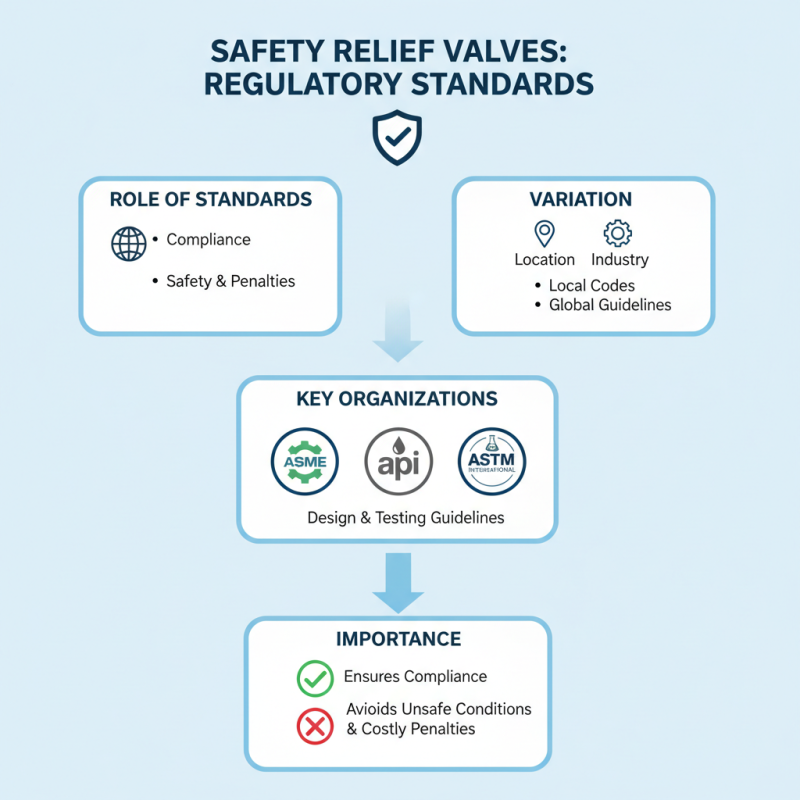

When selecting safety relief valves, regulatory standards play a crucial role. These standards vary by location and industry. Familiarizing yourself with local codes ensures compliance. Standards such as ASME, API, and ASTM provide guidelines on design and testing. Ignoring these can lead to unsafe conditions and costly penalties.

It’s essential to assess your specific operational needs. Different applications have unique requirements. For example, a valve in a high-pressure system may need different specifications than one in a low-pressure setup. Additionally, installation environments can impact performance. Fluctuating temperatures or corrosive materials may necessitate specialized valves.

Consulting with experts is often beneficial. Yet, there’s often a gap in understanding. Some professionals may not keep up with evolving standards. This could lead to suboptimal choices. Engaging with knowledgeable sources will guide you through complexities. Assessing compliance might involve additional paperwork or inspections, but these steps are necessary for safe operations.

Related Posts

-

How to Choose the Best Safety Relief Valve for Your Application

-

Understanding the Importance of Relief Valves in Industrial Applications

-

What is a Pressure Vacuum Relief Valve and How Does It Work?

-

Top 10 Safety Valve Types for Optimal Pressure Control and System Safety

-

10 Essential Tips for Choosing the Right Pressure Release Valve

-

2026 Best Relief Valve Options for Optimal Performance and Safety?