2025 Guide: How to Choose the Right Pressure Valve for Your Needs

When it comes to selecting the right pressure valve for your specific applications, the nuances can be crucial to the overall efficiency and safety of your operations. An expert in the pressure valve industry, Dr. Emily Carter, emphasizes, "Choosing the correct pressure valve is essential not only for performance but also for ensuring system integrity and reliability." With an ever-evolving landscape of technologies and materials, understanding the different types of pressure valves, their functionalities, and the specific requirements of your system is paramount.

The decision-making process involves analyzing various factors including the nature of the media being controlled, the operating pressure and temperature, and the environment in which the valve will function. A misstep in choosing the right pressure valve can lead to significant operational challenges, from inefficiencies to safety hazards. Therefore, this guide aims to provide a comprehensive breakdown of key considerations and expert insights, ensuring that you are equipped with the necessary knowledge to make informed decisions tailored to your industrial needs.

Factors to Consider When Selecting a Pressure Valve for Specific Applications

When selecting a pressure valve for specific applications, several critical factors must be taken into consideration to ensure optimum performance and safety. Firstly, understanding the required pressure rating is essential. According to industry reports from the American Society of Mechanical Engineers (ASME), improper pressure ratings account for nearly 25% of equipment failures in process industries. It is crucial to match the valve’s pressure rating not only to the system’s maximum allowable working pressure but also to account for potential pressure fluctuations that could occur during operation.

Another key factor is the type of media the valve will control. Research published by the International Journal of Fluid Mechanics highlights that compatibility with the media affects not only the valve’s lifespan but also its operational efficiency. For example, corrosive materials may necessitate the use of special coatings or materials to prevent wear and tear. Additionally, temperature settings associated with the process fluids can impact valve selection; high-temperature applications may require valves that can withstand thermal expansion and contraction without compromising their integrity.

Lastly, the specific application context, such as whether the valve is used in a shut-off, control, or safety relief capacity, plays a vital role in selection. A study from the Valve Manufacturers Association indicates that utilizing the correct valve type for the intended function can improve energy efficiency by up to 30%, ultimately contributing to reduced operational costs. By carefully evaluating these factors, organizations can make informed decisions that enhance safety and operational efficiency in their applications.

2025 Guide: Pressure Valve Selection Analysis

Understanding Different Types of Pressure Valves and Their Unique Features

When selecting a pressure valve, it’s essential to understand the different types available and their unique features. Pressure relief valves are designed to protect systems from excessive pressure, opening to release fluid when the pressure exceeds a predetermined limit. These valves can be spring-loaded or pilot-operated, with the latter providing more precise control, making them ideal for critical applications in various industries.

On the other hand, pressure regulating valves maintain a consistent downstream pressure regardless of upstream fluctuations. These valves are particularly useful in systems requiring stable pressure, such as in gas and water distribution networks. Another type worth considering is the back pressure valve, which is used to maintain a specified pressure in a discharge line, ensuring that upstream conditions are optimal for processes like chemical reactions or fluid transfer. Understanding these types and their specific applications will lead to a better-informed decision for your needs.

2025 Guide: How to Choose the Right Pressure Valve for Your Needs

| Valve Type | Max Pressure (psi) | Body Material | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Safety Valve | 3000 | Stainless Steel | -20 to 400 | Pressure Relief Systems |

| Control Valve | 1500 | Bronze | -40 to 250 | Flow Control in HVAC |

| Relief Valve | 2000 | Carbon Steel | 0 to 300 | Chemical Processing |

| Ball Valve | 6000 | PVC | -15 to 180 | Water Supply Systems |

| Check Valve | 2500 | Ductile Iron | -10 to 250 | Automotive Fuel Systems |

Key Industry Standards and Certifications for Pressure Valve Quality Assurance

When selecting a pressure valve, it's essential to consider key industry standards and certifications that ensure quality assurance and reliability. Among the most recognized standards are the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). Compliance with ASME standards guarantees that the valve is designed to handle specific pressure and temperature ratings safely, while ISO certifications ensure consistent quality and performance across manufacturing processes. These standards help users ascertain that the pressure valves they choose are suitable for their specific applications.

In addition to ASME and ISO, other certifications such as the European Pressure Equipment Directive (PED) and the American National Standards Institute (ANSI) play crucial roles in the evaluation of pressure valves. The PED certification applies to equipment designed for use in Europe and ensures that products meet rigorous safety and performance criteria. Similarly, ANSI sets forth guidelines that enhance compatibility and interoperability in diverse service environments. Understanding these standards allows users to make informed decisions, ensuring that their pressure valves not only meet regulatory requirements but also uphold safety and efficiency in their operations.

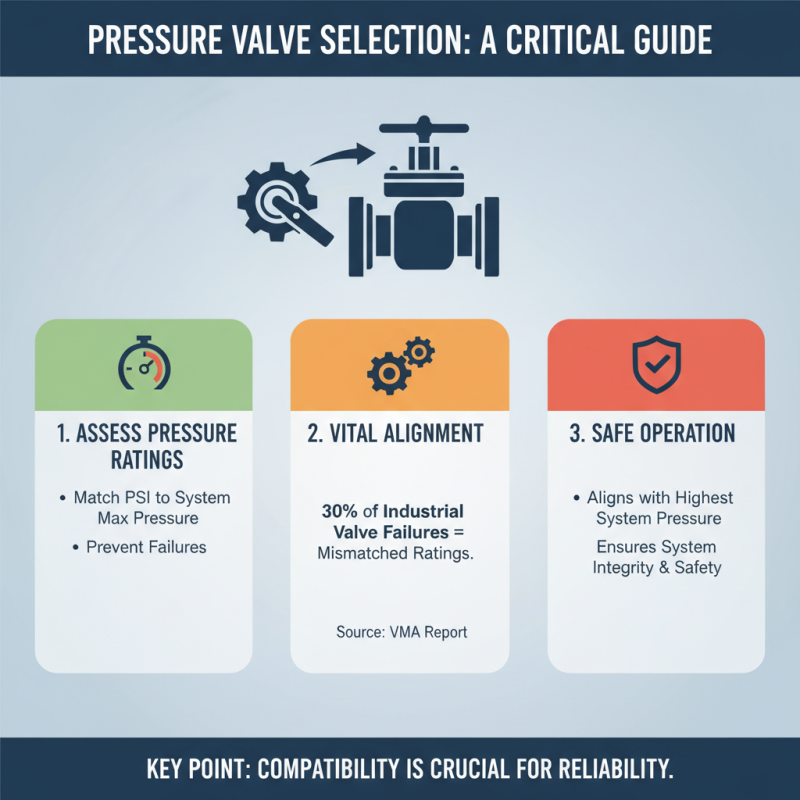

Assessing Pressure Ratings: How to Match Valves to System Requirements

When selecting a pressure valve, it's crucial to assess the pressure ratings to ensure compatibility with your system's requirements. According to a recent report by the Valve Manufacturers Association (VMA), nearly 30% of industrial valve failures are attributed to mismatched pressure ratings. This underscores the importance of selecting a valve that can withstand the operating pressures of your specific application. The valve’s pressure rating, typically expressed in pounds per square inch (PSI), must align with the highest pressure the system will encounter to prevent catastrophic failures and ensure safe operations.

Furthermore, understanding the differential pressure between the inlet and outlet can significantly influence the choice of valve. The Fluid Power Journal indicates that improper pressure differential handling leads to inefficient system performance in over 40% of cases. Valves must be rated not just for the maximum working pressure but also for the maximum expected differentials during operation. This ensures that the valve performs optimally throughout its lifespan, minimizing risk and enhancing reliability. By prioritizing these critical assessments, engineers can effectively match valves to their system requirements, ultimately leading to improved operational efficiency and safety in various industrial applications.

Cost-Benefit Analysis: Investing in the Right Pressure Valve for Longevity

When selecting a pressure valve, a crucial aspect to consider is the cost-benefit analysis that accompanies your investment. According to industry reports, the right pressure valve can reduce operational costs by up to 30% over its lifespan. This reduction is primarily due to improved efficiency and minimized downtime, highlighting the financial significance of making an informed decision. Investing in high-quality valves that are tailored to your specific operational needs may incur a higher initial cost, but the long-term savings on maintenance and repair can be substantial.

Moreover, longevity is a key factor in evaluating the performance of pressure valves. Research indicates that valves built with durable materials and advanced technology can last anywhere from 15 to 30 years, while their lower-quality counterparts may need replacement within a few years. This lifespan not only affects your budget but also the sustainability of your operations. Organizations that invest in robust systems that require less frequent replacement and maintain optimal performance over time can perform better environmentally and economically, translating to a more resilient business model in competitive markets.

Related Posts

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

10 Essential Tips for Choosing the Right Pressure Release Valve

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges