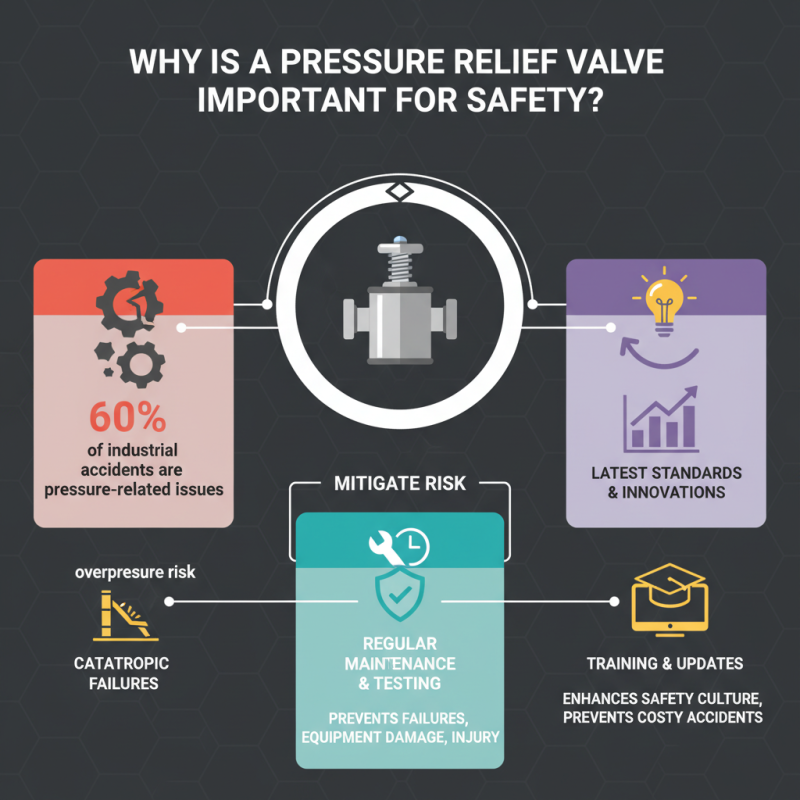

Why is a Pressure Relief Valve Important for Safety?

In industrial settings, a pressure relief valve is critical for maintaining safety and operational integrity. According to the Chemical Safety Board, over 60% of industrial accidents are linked to pressure-related issues. The role of a pressure relief valve is to mitigate the risk of overpressure, which can lead to catastrophic failures. As industry expert Dr. Emily Thompson states, "The failure to implement effective pressure relief systems can compromise both safety and efficiency."

Often, companies underestimate the importance of regular maintenance and testing of these valves. Simple oversight can result in significant hazards. For example, an untested pressure relief valve might fail during a critical moment, leading to equipment damage or injury. The need for vigilance in monitoring valve performance is paramount.

Furthermore, many industries are not fully aware of the latest standards and innovations in pressure relief valve technology. This gap in knowledge can lead to outdated systems that are ill-equipped to handle modern pressures. Reflecting on safety measures is essential. Investing in training and updates can prevent costly accidents and enhance overall safety culture.

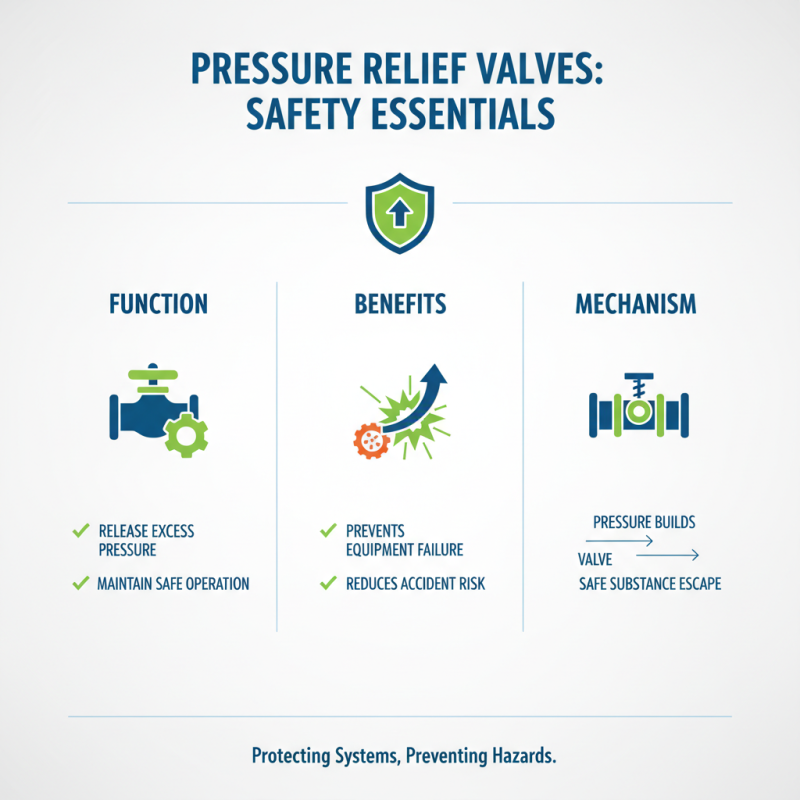

Understanding Pressure Relief Valves and Their Functionality

Pressure relief valves are critical components in various systems. They help maintain safe operating conditions by releasing excess pressure. This prevents equipment failure and reduces the risk of accidents. When a system builds up too much pressure, these valves activate. As a result, they let hazardous substances escape safely.

Understanding how pressure relief valves function is essential. They typically contain a spring-loaded mechanism. When pressure exceeds a preset limit, the valve opens. However, not all relief valves work the same way. Some may not open promptly, leading to dangerous situations. Regular maintenance is vital to ensure they function correctly.

Many people overlook their importance until issues arise. Failing to check these valves can result in catastrophic failures. Routine inspections can prevent such disasters. Training operators to recognize warning signs is crucial. Inadequate knowledge can lead to dangerous scenarios. Pressure relief valves are small but powerful safeguards in any system.

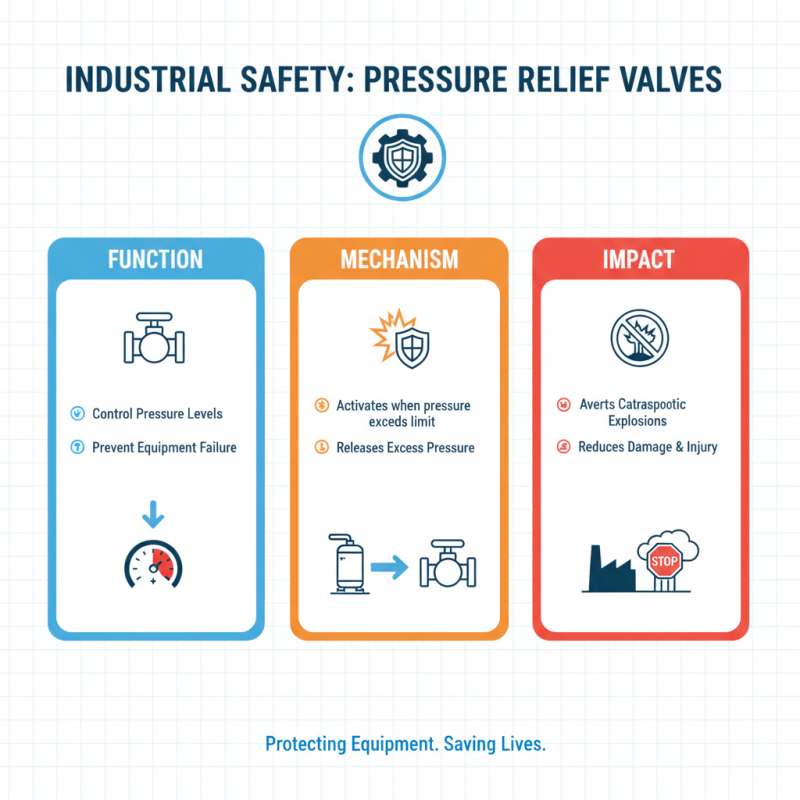

The Role of Pressure Relief Valves in Industrial Safety Systems

Pressure relief valves (PRVs) play a crucial role in industrial safety systems. They are designed to protect equipment from overpressure situations. According to a report by the American Society of Mechanical Engineers, nearly 40% of industrial accidents stem from pressure-related failures. This highlights the need for effective pressure management.

In high-pressure environments, failing to control pressure can lead to catastrophic events. PRVs release excess pressure, preventing explosions. A well-maintained valve can significantly reduce risks. Studies suggest that facilities with proper PRVs experience 30% fewer incidents. This data underlines the importance of regular maintenance and inspection.

While PRVs are essential, they are not foolproof. Human error in installation and maintenance can compromise their effectiveness. Many facilities overlook routine checks. This negligence can lead to serious safety hazards. It's vital for industries to prioritize proper training for personnel handling PRVs. Understanding their function can save lives.

Importance of Pressure Relief Valves in Industrial Safety Systems

How Pressure Relief Valves Prevent Equipment Failure and Explosions

Pressure relief valves play a crucial role in industrial safety. They are essential components designed to control pressure levels within equipment. When pressure builds up beyond safe limits, these valves activate. They release excess pressure, preventing potential equipment failure. This mechanism averts catastrophic explosions that can cause significant damage and injury.

The failure of a pressure relief valve can have dire consequences. If a valve gets stuck or fails to open, pressure continues to rise. This can lead to bursting pipes or ruptured vessels. In some cases, operators might overlook regular maintenance checks. This oversight further increases risks. Proper inspection and testing should be routine to ensure reliability.

Understanding the operational limits of a pressure relief valve is vital. Each valve is designed for specific pressure ranges. Miscalculating these limits can lead to severe outcomes. Operators must be trained to recognize signs of valve malfunction. Ignoring these indicators can be costly. Therefore, prioritizing safety measures is essential to prevent serious incidents.

Maintenance Practices for Ensuring Pressure Relief Valve Effectiveness

Pressure relief valves play a crucial role in maintaining safety within industrial systems. Regular maintenance practices are essential to ensure their effectiveness. Checking for leaks is vital. A small leak can indicate a bigger problem. Inspect the valve's spring and actuator regularly to avoid malfunction. Dust and contaminants can impair performance.

Testing the valve allows you to see if it opens at the set pressure. It’s not enough to assume it works. Some operators overlook this step, leading to potential failures. Additionally, proper cleaning should be a routine task. A dirty valve could cause it to stick, resulting in dangerous pressure buildup.

Documentation of maintenance activities is often neglected. Keeping accurate records helps track the valve’s history and performance. It also simplifies troubleshooting in the future. Operators should periodically review these records to spot trends. Regular training on pressure relief systems is recommended but often falls short. Awareness of these practices enhances safety and reduces risks in operations.

Regulatory Standards and Compliance for Pressure Relief Valves in Industry

In industrial settings, pressure relief valves (PRVs) are crucial for ensuring safety and compliance. According to a report by the American Society of Mechanical Engineers (ASME), over 30% of industrial accidents stem from pressure-related issues. These incidents often trace back to inadequate pressure relief systems. PRVs serve as the first line of defense, preventing catastrophic failures when equipment is over-pressurized. Proper installation and regular maintenance are vital for their efficacy.

Regulatory standards for PRVs are stringent. The Occupational Safety and Health Administration (OSHA) mandates compliance with specific guidelines. These include pressure settings, API standards, and material specifications. Non-compliance can lead to hefty fines, not to mention safety risks. A survey by the National Board of Boiler and Pressure Vessel Inspectors revealed that nearly 40% of inspected valves did not meet these critical standards. This raises questions about where improvements are needed.

Companies must regularly audit their systems. Many still overlook basic maintenance tasks. Regular inspections can significantly reduce risks. Using advanced monitoring technology can also improve compliance. Yet, educational gaps still exist. Workers need ongoing training to stay updated on evolving regulations and best practices.

Why is a Pressure Relief Valve Important for Safety? - Regulatory Standards and Compliance for Pressure Relief Valves in Industry

| Aspect | Description | Regulatory Standard | Compliance Requirement |

|---|---|---|---|

| Safety Function | Prevents overpressure in systems | ASME Section I | Must meet specified set pressure ratings |

| Material Standards | Ensures durability and reliability | ASTM A105 | Material certification required |

| Testing Requirements | Regular inspection and testing protocols | API 520 | Periodic testing to validate performance |

| Installation Guidelines | Proper placement and alignment are critical | NFPA 58 | Follow manufacturer installation instructions |

| Documentation | Maintain records for compliance audits | ISO 9001 | Documentation of testing and maintenance |

Related Posts

-

2025 Guide: How to Choose the Right Pressure Valve for Your Needs

-

Understanding the Importance of Safety Valves in Industrial Applications

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023