Understanding the Importance of Safety Valves in Industrial Applications

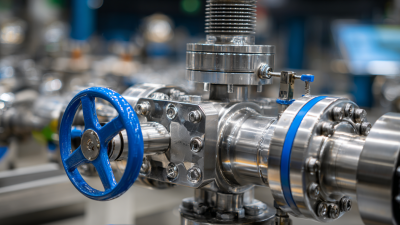

In industrial applications, the significance of safety valves cannot be overstated. As the first line of defense against overpressure situations, these critical components ensure operational safety and prevent catastrophic failures. According to industry expert Dr. Emily Harris, a leading authority in pressure management, "The efficacy of safety valves directly impacts the overall safety of industrial systems, making them essential for risk mitigation." Her insights highlight the crucial role safety valves play in safeguarding machinery and personnel alike.

As we explore the importance of safety valves in various industrial sectors, we will provide practical tips and strategies that professionals can implement to enhance safety and compliance. By prioritizing the functionality of safety valves, organizations can foster a culture of safety that protects both their assets and their workforce.

The Role of Safety Valves in Industrial Systems: An Overview

Safety valves are crucial components in industrial systems, ensuring the integrity and safety of operations across various sectors. According to the American Society of Mechanical Engineers (ASME), approximately 20% of industrial accidents are linked to equipment failure, where improperly functioning safety valves play a significant role. These valves act as critical safeguards, regulating pressure within systems to prevent catastrophic failures. In high-stakes environments, such as chemical plants and power generation facilities, their role cannot be overstated; they are designed to release excess pressure, thereby preventing potential explosions or hazardous leaks that could endanger lives and disrupt production.

**Tips:** Regular maintenance and testing of safety valves are essential to ensure their reliability. Implementing a preventive maintenance schedule can help identify issues before they escalate, reducing the risk of malfunction during critical operations.

Moreover, industries are increasingly adopting advanced monitoring technologies to oversee safety valve performance in real time. A report from the National Board of Boiler and Pressure Vessel Inspectors indicates that effective monitoring can reduce the risk of valve failures by up to 40%. By utilizing smart sensors and predictive analytics, companies can enhance the operational safety of their systems, ensuring compliance with safety regulations while optimizing productivity.

**Tips:** Invest in training for personnel on the importance of safety valve monitoring. A well-informed team can identify early signs of wear or malfunction, which is vital for maintaining operational efficiency.

Types of Safety Valves and Their Specific Applications

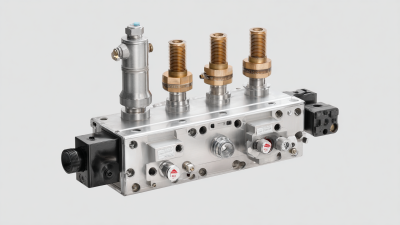

Safety valves are critical components in industrial applications, designed to protect equipment and personnel from excessive pressure. There are several types of safety valves, each tailored for specific applications. For instance, the spring-loaded safety valve is widely used in various industries due to its simplicity and reliability. According to a report by Research and Markets, the global market for spring-loaded safety valves is expected to reach $2 billion by 2025, driven by increasing regulatory demands for safety in industries such as oil and gas, chemical processing, and power generation.

Another significant type is the pilot-operated safety valve, which is typically employed in high-pressure applications. This valve type allows for more precise control due to its ability to adjust the opening and closing based on system pressure. A study from the International Journal of Engineering Research highlights that pilot-operated safety valves can handle pressures exceeding 10,000 psi, making them ideal for specialized sectors like aerospace and pharmaceuticals where safety and efficacy are paramount. By understanding the specific applications and strengths of different safety valves, industries can effectively mitigate risks and enhance operational safety.

Understanding the Importance of Safety Valves in Industrial Applications - Types of Safety Valves and Their Specific Applications

| Type of Safety Valve | Application Area | Pressure Rating | Material | Standards Complied |

|---|---|---|---|---|

| Spring-Loaded Valve | Steam Systems | 150-300 PSI | Stainless Steel | ASME, API |

| Pilot-Operated Valve | Gas Pipelines | 100-2000 PSI | Carbon Steel | PED, ISO |

| Balanced Bellows Valve | Chemical Processing | 50-1500 PSI | Alloy Steel | API, NFPA |

| Safety Relief Valve | Oil Refineries | 50-1000 PSI | Bronze | ASME, API |

| Vacuum Relief Valve | Storage Tanks | Vacuum Service | Plastic, Stainless Steel | API, NFPA |

Key Benefits of Implementing Safety Valves in Industrial Operations

Safety valves play a critical role in industrial operations by providing essential protection against overpressure situations. These devices are designed to automatically release excess pressure, thereby preventing explosions and equipment failures that can lead to significant safety hazards and financial losses. Implementing safety valves ensures compliance with industry regulations and enhances overall operational reliability, making them a fundamental component in many industrial systems.

In addition to safety improvements, the adoption of safety valves can lead to notable cost savings for companies. By minimizing the chances of catastrophic failures, businesses reduce the risk of costly downtime and repairs. Furthermore, with advances in technology, such as the integration of digital twins, safety valves can be monitored and managed more effectively, streamlining maintenance processes and optimizing performance. This holistic approach not only enhances safety but also supports companies in their quest for operational excellence and sustainability in an increasingly competitive market.

Challenges in Safety Valve Design and Maintenance Practices

In industrial applications, safety valves play a critical role in protecting equipment and personnel from overpressure situations. However, the design and maintenance of these essential components present several challenges that must be effectively managed. One prevalent issue is ensuring that safety valves are correctly sized for the specific application; an undersized valve may fail to relieve pressure adequately, while an oversized valve can lead to operational inefficiency. Another challenge lies in the materials used in manufacturing safety valves. Exposure to corrosive substances or extreme temperatures can significantly affect valve performance and longevity, necessitating careful selection of materials based on the operating environment.

To navigate these challenges successfully, it's essential to implement rigorous maintenance practices. Regular inspection and testing of safety valves can help identify any signs of wear or malfunction before they become critical failures. Additionally, adhering to manufacturer guidelines for installation and maintenance is vital to ensure optimal performance.

**Tips:** Schedule routine maintenance checks and consider utilizing advanced monitoring technologies that can alert operators to potential issues. Educate staff on the importance of safety valves and proper handling techniques to prevent damage during routine operations. Understanding and addressing these challenges can enhance safety and reliability in industrial processes.

Understanding the Importance of Safety Valves in Industrial Applications

This chart illustrates the various challenges faced in the design and maintenance of safety valves in industrial applications. The data shows that regulatory compliance is considered the most significant challenge, followed by design challenges and maintenance issues.

Regulatory Standards and Compliance for Safety Valves in Industry

Safety valves are critical components in various industrial applications, ensuring the safe operation of equipment and systems under pressure. Compliance with regulatory standards is essential in the design and maintenance of these valves, as overlooking such regulations can lead to catastrophic failures and significant financial losses. According to a report by the American Society of Mechanical Engineers (ASME), about 20% of industrial accidents are attributed to pressure-related failures, underscoring the importance of adhering to established safety standards.

In many regions, safety valves are governed by strict regulatory frameworks that dictate their design, testing, and maintenance procedures. For instance, the API 520 guideline provided by the American Petroleum Institute (API) specifies the criteria for the sizing and selection of safety valves used in oil and gas operations. Failure to comply with such guidelines not only risks safety but also can result in hefty fines and legal repercussions. Data from the National Board of Boiler and Pressure Vessel Inspectors indicates that proper compliance can reduce the likelihood of pressure vessel accidents by over 60%, highlighting the critical need for industry players to prioritize regulatory adherence concerning safety valves.

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding Hydraulic Relief Valves: Essential Insights for Efficient Fluid Control Systems