Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

In the quest for optimal system performance and safety, understanding the critical role of relief valves emerges as a fundamental priority for engineers and operators alike. Relief valves serve as essential safety devices that prevent the dangerous consequences of pressure surges, which can lead to equipment failure, operational downtime, and even catastrophic incidents. By allowing excess pressure to escape, these valves maintain system integrity and enhance overall efficiency. As industries continuously seek to improve their processes, the examination of relief valve functionality, selection, and maintenance becomes increasingly important. This article delves into the various types of relief valves, their operational principles, and best practices for maximizing system efficiency while ensuring safety standards are met. Through this exploration, we establish the undeniable significance of relief valves in sustaining operational excellence and safeguarding against unforeseen pressure fluctuations.

Importance of Relief Valves in Pressure Management and System Safety

Relief valves are essential components in maintaining pressure management within various industrial systems. Their primary function is to monitor and control the pressure levels, ensuring that they do not exceed safe thresholds. By automatically releasing excess pressure, relief valves mitigate the risk of equipment failure and catastrophic incidents. This proactive measure protects not only the system's integrity but also the safety of personnel and the surrounding environment.

In addition to their safety role, relief valves contribute to the overall efficiency of a system. By preventing pressure surges, they help maintain optimal operating conditions, which can lead to improved performance and reduced operational costs. Regular maintenance and testing of relief valves are crucial to ensure their reliability. When functioning correctly, relief valves offer peace of mind, knowing that the system is safeguarded against unforeseen fluctuations, ultimately enhancing both efficiency and safety in industrial operations.

Statistics on Pressure Surge Incidents and Their Costs to Industries

Pressure surges can have devastating effects on various industries, leading to equipment failure and costly downtime. According to a report by the U.S. Department of Labor, pressure surges account for approximately 50% of mechanical failures in industrial systems. The financial implications are significant; the average cost of a single pressure surge incident can range from $20,000 to $200,000, depending on the scale of operations and the extent of damage. This highlights the urgent need for effective pressure management solutions, particularly the use of relief valves.

In sectors such as oil and gas, chemical processing, and manufacturing, statistics suggest that inadequately managed pressure surges can result in not only financial loss but also safety hazards. A study conducted by the Occupational Safety and Health Administration (OSHA) revealed that over 30% of major industrial accidents are attributed to improper pressure regulation, emphasizing the critical role of relief valves in mitigating these risks. By efficiently managing excess pressure, these valves not only help in preventing costly surges but also protect workers and the environment from potential disasters.

Comparative Analysis: Traditional Valves vs. Modern Relief Valve Technologies

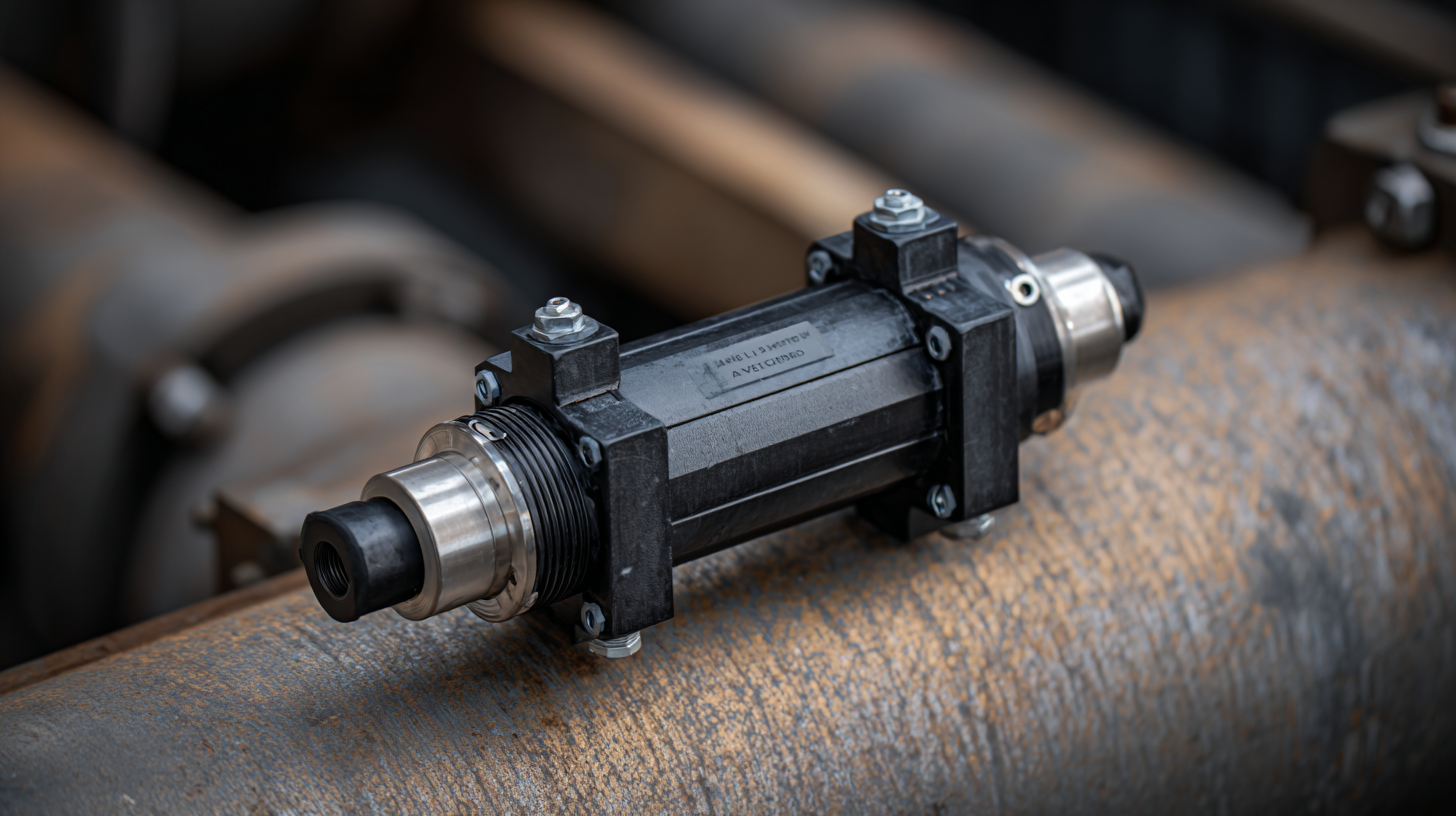

In the realm of industrial systems, the choice of relief valves plays a pivotal role in ensuring operational safety and efficiency. Traditional valves, often mechanical in design, have long been utilized to manage pressure surges. These valves typically rely on a spring-loaded mechanism to open at predetermined pressure levels. While effective, traditional valves can face challenges such as lag time in response and potential for mechanical wear, which may compromise their reliability over time.

In contrast, modern relief valve technologies have been developed using advanced materials and smart controls that enhance their responsiveness and durability. Digital pressure sensors and automated actuator systems allow these valves to react instantaneously to pressure changes, significantly reducing the risk of surges. Furthermore, the integration of predictive maintenance tools helps to monitor valve performance in real-time, leading to increased system reliability. This comparative analysis reveals that adopting modern relief valve technologies not only enhances safety but also optimizes overall system efficiency, marking a significant advancement over traditional designs.

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

| Valve Type | Pressure Range (psi) | Response Time (ms) | Leakage Rate (%) | Durability (Cycles) | Cost ($) |

|---|---|---|---|---|---|

| Traditional Relief Valve | 0-3000 | 200 | 5 | 50000 | 150 |

| Modern Spring-Loaded Valve | 0-5000 | 90 | 2 | 100000 | 200 |

| Electronic Relief Valve | 0-10000 | 50 | 1 | 200000 | 500 |

| Modular Relief Valve | 0-7500 | 80 | 3 | 120000 | 300 |

Best Practices for Selecting and Maintaining Relief Valves in Various Applications

Selecting and maintaining relief valves is crucial for ensuring system efficiency and preventing pressure surges. When choosing a relief valve, it's vital to consider the specific application and operating conditions. Factors such as the fluid type, pressure, temperature, and flow rate significantly influence the selection process. For instance, in high-temperature environments, materials that can withstand thermal expansion and corrosion should be prioritized. Additionally, ensure that the valve's capacity aligns with the system’s maximum potential pressure to prevent overpressure scenarios effectively.

Proper maintenance of relief valves is equally important. Regular inspections should be conducted to check for signs of wear, corrosion, or blockages that might inhibit their performance. It’s also essential to test the valves periodically to confirm they open and close correctly in response to changes in pressure. Documenting maintenance activities helps ensure compliance with safety standards and enables quick identification of any recurring issues. By adhering to these best practices, operators can enhance system reliability and safety, thus maximizing overall operational efficiency.

Impact of Relief Valves on Overall System Efficiency and Lifecycle Costs

Relief valves play a crucial role in enhancing the overall system efficiency and managing lifecycle costs in various industrial applications. According to the American Society of Mechanical Engineers (ASME), ineffective pressure management can lead to unforeseen equipment failures that escalate maintenance and operational costs by up to 30%. By preventing pressure surges, relief valves help maintain optimal operating conditions, thus extending the lifespan of system components and reducing the frequency of replacements.

Furthermore, a study conducted by the International Association for the Properties of Water and Steam (IAPWS) estimates that effective relief valve operation can save an average facility approximately $50,000 annually in energy costs alone. When pressure surges occur, systems may require additional energy to restore equilibrium, leading to inefficient operation. A well-calibrated relief valve mitigates these fluctuations, promoting a stable environment that optimizes energy consumption and overall performance, ultimately contributing to lower lifecycle costs.

Deploying advanced relief valves can thus serve as a proactive investment, enhancing both economic and operational efficiency in the long run.

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications