Why Do You Need a Pressure Safety Valve for Your Systems?

In the world of industrial safety, the pressure safety valve is a critical component. Experts agree on its importance. "A pressure safety valve saves lives," says Dr. Emily Carter, a leading safety engineer. Her words echo the sentiment that without effective safety measures, systems can face disastrous failures.

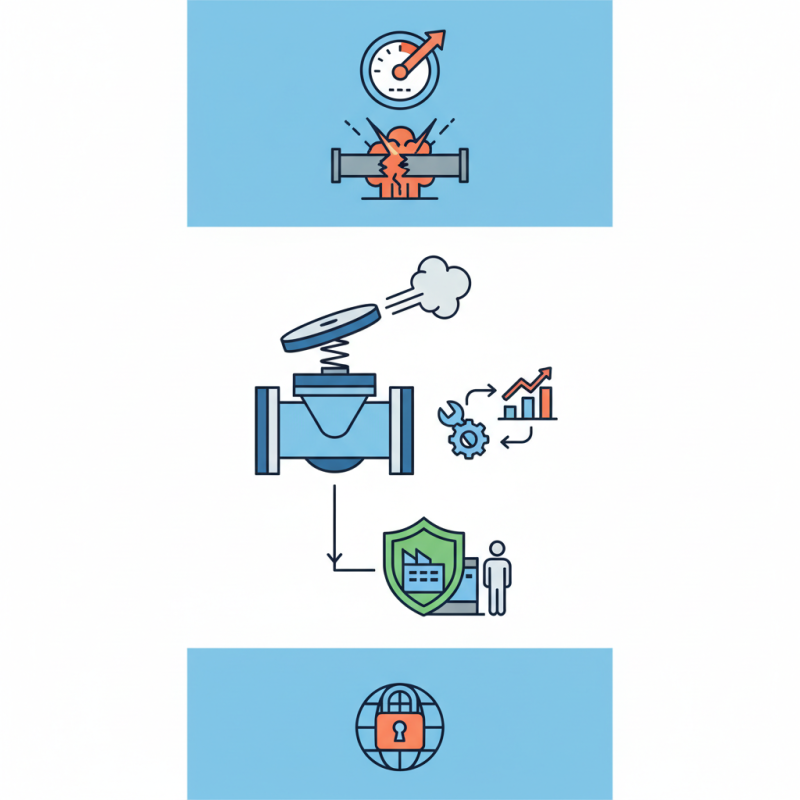

Every industrial system operates under pressure. When that pressure exceeds safe limits, risks increase. A properly functioning pressure safety valve acts as a safeguard. It prevents excessive pressure buildup and potential explosions. Yet, too many systems neglect this essential device. This oversight can lead to catastrophic incidents.

The importance of proper maintenance cannot be overstated. Many companies fail to regularly test their pressure safety valves. This oversight exposes them to significant hazards. Understanding the value of these valves is vital. They not only protect equipment but also ensure worker safety. Investing in reliable valves is essential for any operational system.

Importance of Pressure Safety Valves in Industrial Systems

Pressure safety valves play a crucial role in industrial systems. They protect equipment by releasing excess pressure when needed. This prevents catastrophic failures, which can lead to injuries or significant damage. Safety valves act quickly to maintain a safe operating environment, ensuring reliability in processes.

In many industries, pressure build-up can occur unexpectedly. When steam, gas, or liquid pressure exceeds safe limits, danger looms. A malfunctioning pressure safety valve can lead to disastrous outcomes. Regular maintenance is essential for these valves to function correctly. Operators must be vigilant, checking for wear and tear.

Moreover, the installation of safety valves requires careful consideration. Too small a valve can fail to release pressure effectively. A valve that is too large may not maintain proper system pressure. Balancing these factors is not always straightforward. Each system is unique, which adds complexity to selection and installation. Understanding these nuances is key to enhancing safety measures.

Understanding the Functionality of Pressure Safety Valves

Pressure safety valves play a critical role in many systems. They are designed to release excess pressure, preventing dangerous situations. When pressure builds up beyond safe levels, these valves open automatically. This action protects equipment and human life.

Understanding how these valves function is essential. They consist of a spring-loaded mechanism. When pressures exceed the set limit, the valve pops open. The system can then vent excess pressure safely. These devices are not foolproof. They require regular maintenance and testing. Neglecting these checks can lead to failures when you need them most.

The design and placement of pressure safety valves are crucial. An ideal valve must be suitable for the specific application. Improper specifications can compromise safety. This highlights the importance of selecting the right valve for every unique system. A mistake might mean the difference between safety and disaster. Users should remain vigilant, paying attention to any signs of malfunction.

Importance of Pressure Safety Valves Across Different Industries

The following chart illustrates the significance of pressure safety valves in various industries, highlighting the percentage of systems that require such valves to ensure safety and compliance with regulations.

Common Applications of Pressure Safety Valves in Various Industries

Pressure safety valves (PSVs) play a critical role in various industries. These valves ensure safety by releasing excess pressure. They are essential in oil and gas, chemical processing, and manufacturing sectors. For instance, in the oil industry, PSVs address high-pressure surges in pipelines. According to a 2022 industry report, improper functioning of PSVs contributed to 35% of industrial accidents. This statistic highlights the significance of reliable pressure management systems.

In chemical plants, PSVs protect against hazardous material leaks. They are designed to activate when pressure exceeds safe levels. Reports indicate that PSVs saved approximately $10 million in potential damages in 2021 alone. Regular maintenance and testing of these valves are crucial. Negligence can lead to catastrophic failures and costly repairs. Always document maintenance schedules.

Tip: Regularly inspect your pressure safety valves. Ensure they are calibrated correctly to avoid risks.

In manufacturing, PSVs safeguard equipment from pressure-related issues. A malfunctioning valve can disrupt entire production lines. A recent survey showed that 60% of manufacturers experienced downtime due to PSV failures. Addressing these vulnerabilities should be a priority. Ensure that all workers understand the importance of pressure safety valves.

Tip: Train your staff on PSV operations and emergency procedures. Preparedness can save lives and resources.

Why Do You Need a Pressure Safety Valve for Your Systems? - Common Applications of Pressure Safety Valves in Various Industries

| Industry | Common Applications | Pressure Safety Valve Role | Typical Set Pressure (psi) |

|---|---|---|---|

| Oil & Gas | Refineries, Pipeline Systems | Prevent pressure buildup and protect equipment | 1500 |

| Pharmaceuticals | Production Vessels, Sterilization Units | Ensure safe operation during processing | 100 |

| Food & Beverage | Pasteurization, Pressurized Tanks | Maintain safety during thermal processes | 50 |

| Chemical Processing | Reactor Vessels, Storage Tanks | Prevent explosive incidents due to pressure | 900 |

| Water Treatment | Boiler Systems, Filtration Units | Protect systems from overpressure | 80 |

Factors to Consider When Selecting a Pressure Safety Valve

When selecting a pressure safety valve, it’s crucial to consider several factors.

The valve’s set pressure is essential. It should match the system's requirements.

Too high, and it won't function; too low, and it may cause damage. A miscalculated pressure setting can lead to serious issues.

Temperature tolerance is another key element. The valve must withstand the operating conditions.

If it can't handle the heat, it may fail when needed most. Look at the materials used too.

Corrosion-resistant options often perform better. But not all applications require expensive materials.

Choose wisely based on the environment.

Flow capacity should also be evaluated. A valve with insufficient capacity may not relieve pressure fast enough.

This can result in system failure or worse. Think about the size and layout of your system.

A poorly placed valve can lead to function misalignment. It’s important to review all these considerations.

The right choice can save both time and money.

Maintenance Best Practices for Ensuring Valve Reliability

Maintaining pressure safety valves is crucial for system reliability. Regular maintenance can prevent dangerous failures. Industry data shows that 15% of pressure safety valve failures are due to improper maintenance practices. Ensuring these devices work correctly protects both personnel and equipment.

To enhance valve reliability, implement a routine inspection schedule. Check for leaks and signs of wear. Corrosion can compromise a valve's effectiveness. A recent survey by the American Society of Mechanical Engineers indicates that around 30% of valves experience corrosion, reducing their lifespan.

Tips: Always document inspections and repairs. This builds a reliable maintenance history. Consider training your team on best practices for valve upkeep. Regular education can reduce mistakes and improve safety. Remember that even small issues can escalate into significant problems if left unaddressed.

Related Posts

-

How to Choose the Best Safety Relief Valve for Your Application

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

Top 10 Safety Valve Types for Optimal Pressure Control and System Safety

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide