What is a Pressure Relief Valve and How Does It Work?

A pressure relief valve is a crucial safety device in various industries. It protects equipment from overpressure situations that could lead to catastrophic failures. According to a recent report by the American Society of Mechanical Engineers (ASME), nearly 60% of industrial accidents could be linked to improper valve functions. Such statistics highlight the importance of understanding how these valves operate.

Industry expert John Smith states, "The effectiveness of pressure relief valves can be the difference between safety and disaster." His insights echo the necessity of regularly testing and maintaining these valves. Yet, many facilities neglect this vital maintenance. It is not uncommon for organizations to overlook routine inspections, leading to failures when they are needed most.

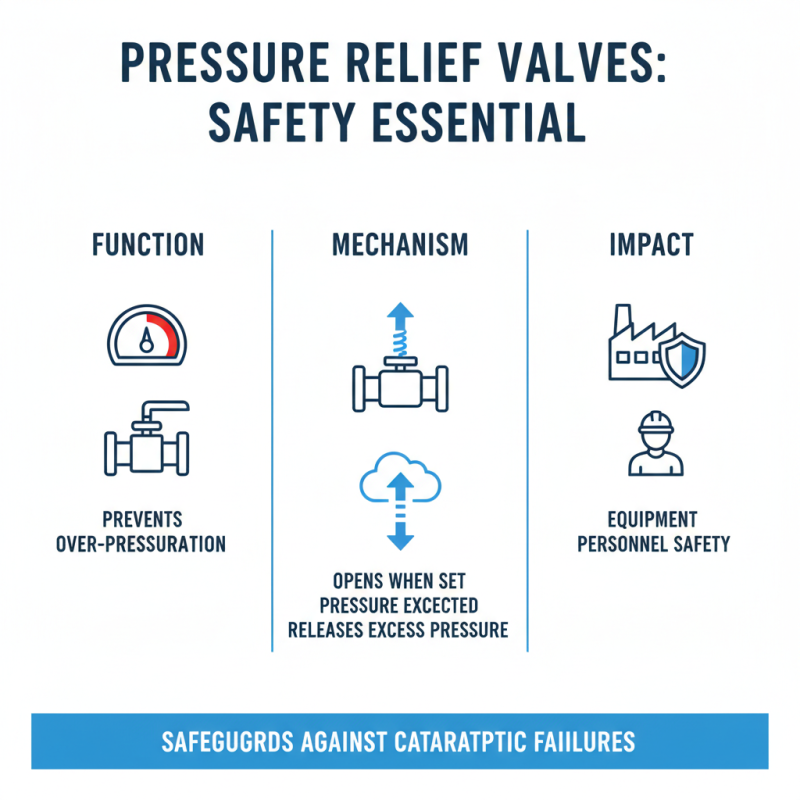

Pressure relief valves are designed to open and release pressure at a predetermined level. This mechanism prevents equipment damage and ensures operational safety. However, improper selection or installation can render these devices ineffective. As industries advance, the complexity of systems increases. The pressure relief valve remains a simple yet critical component that deserves more attention and reflection in safety protocols.

What is a Pressure Relief Valve?

A pressure relief valve is a crucial safety device. It helps prevent system overloads by releasing excess pressure. In many industries, like oil and gas, it is vital for equipment safety. According to a report by the Pressure Relief Valve Association, equipment failures can lead to significant downtime and financial loss.

These valves work automatically. When pressure exceeds a specified limit, the valve opens and releases fluid or gas. This action stabilizes the system's pressure. It may seem straightforward, but not all pressure relief valves function perfectly. Miscalculations in pressure settings can lead to valve failure. A study noted that 30% of pressure relief valves failed during routine testing.

Regular maintenance is key. Neglecting this can result in accidents. Some operators might overlook this, believing their systems are safe. However, the consequences of such oversight can be dire. A reliable pressure relief valve is not just a recommendation; it is a necessity for operational safety. The statistics indicate a clear need to evaluate these safety devices consistently.

Understanding the Mechanism of Pressure Relief Valves

A pressure relief valve is essential in many systems. It prevents excessive pressure build-up. Understanding its mechanism is crucial for safe operations.

When the pressure reaches a certain limit, the valve opens. This allows excess fluid or gas to escape. A spring often controls this action. The adjustments of the spring tension determine the pressure level at which the valve activates. If the spring is too tight, it may not open when needed. If it's too loose, it could open too early.

Materials and design influence performance. Some valves use metal, while others employ plastic. Each has pros and cons. Faulty installations can lead to leaks or failures.

Regular maintenance is vital to ensure proper function. Observing pressure readings is a good practice. Pressure relief valves are small, but they play a significant role. They protect systems from catastrophic failures.

Types of Pressure Relief Valves and Their Applications

Pressure relief valves are essential components in many industries. They help protect systems from excessive pressure by releasing it safely. Different types of pressure relief valves serve various purposes. Understanding these can greatly enhance safety and efficiency.

One common type is the spring-loaded valve. It uses a spring to maintain pressure until a specified limit is reached. When the pressure rises, the spring compresses, allowing fluid to escape. Another type is the pilot-operated valve. This valve requires a smaller pilot pressure to operate, making it sensitive and precise. It's often used in large systems where accurate control is crucial.

Vacuum relief valves are important too. They prevent a vacuum condition that could cause damage. These valves automatically open when pressure falls below a certain level. Each type has unique applications, from industrial tanks to water systems. Not every valve is perfect for every situation. It's essential to analyze the system needs carefully. Mismanagement can lead to system failures.

Pressure Relief Valve Applications

This bar chart illustrates the frequency of application for various types of pressure relief valves. Spring loaded valves are the most commonly used, followed by pilot operated valves. Other types like solenoid activated, thermal relief, and vacuum relief valves have less frequent applications.

Key Components of a Pressure Relief Valve System

A pressure relief valve system is essential in many industrial applications. It prevents excessive pressure buildup in pressurized vessels. The core components include the valve itself, a spring mechanism, and a detecting element. Each part plays a vital role in managing pressure safely.

The valve opens to release pressure when it reaches a preset limit. The spring mechanism determines this limit. If the pressure exceeds what the spring can hold, the valve activates. This action prevents potential explosions or catastrophic failures. However, springs can wear out over time, leading to failures. Regular inspections are crucial to avoid these issues.

The detecting element monitors the pressure and signals the valve. It works hand-in-hand with the spring-loaded mechanism. A malfunction in this part can compromise the entire system. Consider the maintenance routines. Often, they are overlooked, which poses risks. Small leaks in the system can go unaddressed, affecting performance. Proper training and awareness are necessary for operating such systems.

Importance of Pressure Relief Valves in Safety and Maintenance

Pressure relief valves play a crucial role in safety systems across various industries. These devices prevent over-pressurization, which can lead to catastrophic failures. When pressure exceeds a predetermined limit, the valve opens and releases excess pressure. This action safeguards equipment and protects personnel.

Ignoring the need for these valves can be risky. Many facilities overlook maintenance, leading to valve malfunction. Regular inspections are vital to ensure they operate correctly. Operators might not always notice small leaks or wear. This can result in dangerous situations, where pressure builds up unexpectedly.

Integrating pressure relief valves into safety protocols is essential. They act as the last line of defense against system failure. However, relying solely on them is not enough. Comprehensive training on their function is necessary. Operators must recognize their limitations and the importance of regular checks. A proactive approach to safety includes more than just installation; it requires ongoing vigilance.

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

What is a Pressure Vacuum Relief Valve and How Does It Work?

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

2025 Guide: How to Choose the Right Pressure Valve for Your Needs