What is a Pressure Vacuum Relief Valve and How Does It Work?

The functionality of a pressure vacuum relief valve is crucial in ensuring the safe and efficient operation of various systems that handle liquids and gases. Industry reports indicate that improper handling of pressure and vacuum conditions can lead to catastrophic failures, resulting in significant financial losses and environmental hazards. For instance, the American Petroleum Institute highlights that more than 70% of storage tank incidents stem from inadequate pressure and vacuum management, showcasing the importance of implementing effective safety measures.

A pressure vacuum relief valve operates by maintaining a safe balance between internal tank pressure and external atmospheric pressure, preventing excessive pressure buildup or vacuum conditions that could jeopardize system integrity. According to research from the National Fire Protection Association, the installation of reliable pressure vacuum relief valves is a key factor in minimizing risks associated with flammable liquids, further emphasizing their role in industrial applications.

As industries increasingly prioritize safety and compliance with stringent regulations, understanding the mechanics and significance of a pressure vacuum relief valve is paramount. This article will delve into the working principles of this critical device, exploring its design features and the advantages it offers to various sectors that rely on liquid and gas containment systems.

What is a Pressure Vacuum Relief Valve?

A Pressure Vacuum Relief Valve (PVRV) is a crucial safety device commonly used in storage tanks and various industrial settings where liquids are contained. Its primary function is to maintain a balance between the pressure inside the tank and the external atmospheric pressure. This is essential in preventing tank collapse or rupture due to excessive vacuum or pressure during filling, emptying, or temperature fluctuations.

The valve operates through a simple yet effective mechanism. When the internal pressure exceeds a predetermined limit, the valve opens, allowing excess pressure to escape and thus preventing potential hazards. Conversely, when the pressure inside the tank drops unexpectedly, such as during fluid withdrawal, the valve also facilitates air intake to avoid creating a vacuum that could compromise the structural integrity of the tank. By effectively regulating these pressure levels, a Pressure Vacuum Relief Valve ensures safe and efficient operation of storage and processing systems.

Pressure Vacuum Relief Valve Performance Analysis

This chart illustrates the performance metrics of Pressure Vacuum Relief Valves in terms of pressure and vacuum thresholds across various operational conditions. The effectiveness of the valves is measured at different pressure levels, demonstrating their reliability in maintaining system safety.

Principles of Operation for Pressure Vacuum Relief Valves

Pressure vacuum relief valves (PVRVs) are essential components in maintaining the safety and efficiency of storage tanks and other pressurized vessels. They operate based on fundamental principles that balance internal pressure and vacuum conditions, ensuring that the vessel remains functional under varying operational conditions. When the internal pressure exceeds a predetermined level, the valve opens to release excess pressure, preventing potential over-pressurization that could compromise structural integrity. Conversely, when the pressure inside the tank drops below atmospheric pressure, the valve opens to allow air into the system, preventing the tank from collapsing.

According to the 2022 Global Valve Industry Analysis, pressure vacuum relief valves play a critical role in managing the safe transportation of liquids and gases. These valves are designed to activate at specific pressure thresholds, typically ranging from 0.05 to 0.5 psi for pressure relief and -0.1 to -0.3 psi for vacuum relief. This precise control mechanism highlights the significance of selecting appropriate valve settings that align with the particular requirements of storage materials and vessel design. Effective operation of PVRVs contributes to minimizing risks associated with tank failures, thereby enhancing operational safety and compliance with industry standards.

Importance of Pressure Vacuum Relief Valves in Industrial Applications

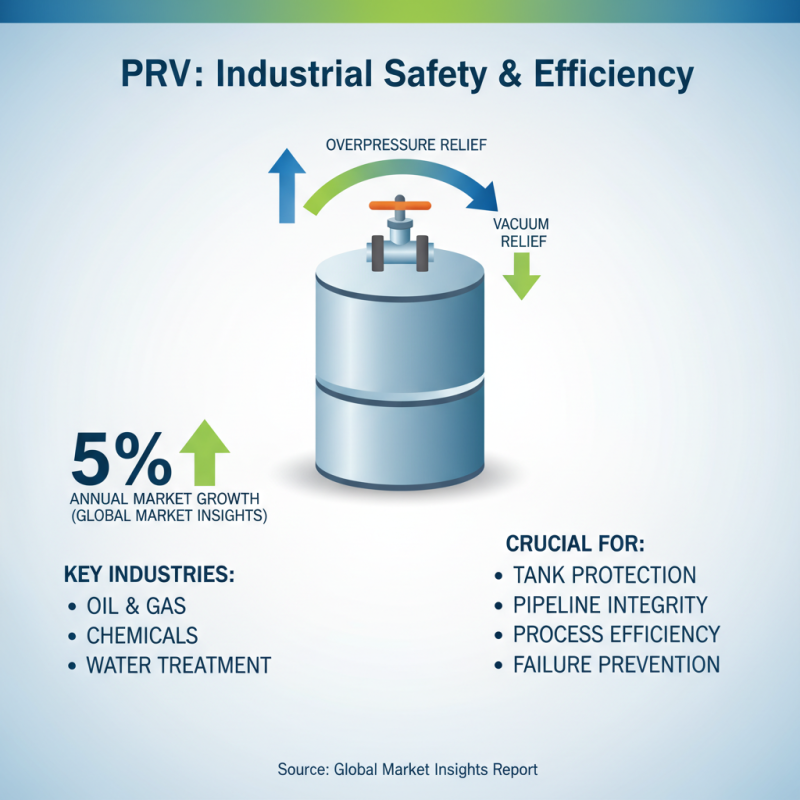

Pressure Vacuum Relief Valves (PVRVs) play a crucial role in maintaining the safety and efficiency of various industrial applications. These valves are essential components for preventing vacuum or overpressure conditions in storage tanks, pipelines, and other pressure-sensitive systems. According to a report by the Global Market Insights, the demand for PVRVs is expected to grow by over 5% annually due to the increasing need for safety solutions in industries such as oil and gas, chemicals, and water treatment. These valves ensure that tanks and vessels can operate efficiently without risking structural integrity or catastrophic failure.

In industrial applications, the significance of PVRVs cannot be overstated. They help in preventing the collapse of storage tanks during drainage and protect against explosive vapor discharge that can occur under overpressure conditions. The Chemical Engineering Magazine highlighted that approximately 30% of industrial accidents related to pressure vessels could have been mitigated with the proper implementation of relief valves. By allowing the safe venting of gases or liquids, these valves contribute significantly to workplace safety and environmental protection, aligning with regulatory standards set by organizations such as OSHA and EPA. The investment in quality pressure vacuum relief valves translates to lower risks, enhanced operational uptime, and compliance with safety regulations, making them indispensable in modern industrial environments.

Key Specifications and Standards for Pressure Vacuum Relief Valves

When considering the functionality and efficiency of pressure vacuum relief valves (PVRVs), understanding their key specifications and relevant standards is essential. PVRVs are critical safety devices in storage tanks, preventing the formation of vacuum and maintaining pressure levels to avoid structural damage. Key specifications typically include set pressure, flow capacity, and materials used, which must align with the specific application and the product stored within the tank. Ensuring that these specifications meet industry standards, such as API 2000 or NFPA 30, is vital to adherence to safety regulations and effective operation.

Tips: Always consult the relevant standards during installation and maintenance procedures to ensure compliance and safety. Regular inspections must be conducted to detect any wear or malfunction in the valves, which can compromise their effectiveness. Additionally, personnel should be trained on the proper operation and troubleshooting of PVRVs to mitigate risks associated with tank overpressure or vacuum events.

Another crucial aspect is the selection of the right valve size and type based on the tank's service conditions. Factors such as product temperature, pressure requirements, and potential venting scenarios must be evaluated. As a best practice, engaging a qualified engineer for system design can further enhance operational safety and reliability while ensuring compliance with specified standards throughout the valve's life cycle.

Common Problems and Maintenance Tips for Pressure Vacuum Relief Valves

Pressure vacuum relief valves (PVRVs) are vital components in maintaining the safety and efficiency of storage tanks and other vessels. However, like any mechanical system, they can encounter various problems over time. Common issues include leaking seals, corrosion, and misalignment, which can affect their performance. Regular inspection is essential to identify these problems early. Operators should check for any visible signs of wear, unusual noises during operation, or abnormal pressure readings that could indicate a malfunction.

To maintain the functionality of pressure vacuum relief valves, several proactive measures can be taken. Routine maintenance checks should involve cleaning the valve seats and ensuring that the moving parts are lubricated appropriately. It is also advisable to conduct pressure tests periodically to ensure the valves are opening and closing at the correct thresholds. Additionally, operators should replace any worn or damaged components promptly to prevent potential hazards and maintain compliance with safety standards. Implementing these maintenance tips can significantly extend the lifespan of PVRVs and reduce the risk of costly operational issues.

Related Posts

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Top 5 Pressure Vacuum Relief Valves: Maximizing Safety and Efficiency

-

10 Essential Tips for Choosing the Right Pressure Release Valve

-

How to Choose the Best Safety Relief Valve for Your Application

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide