2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

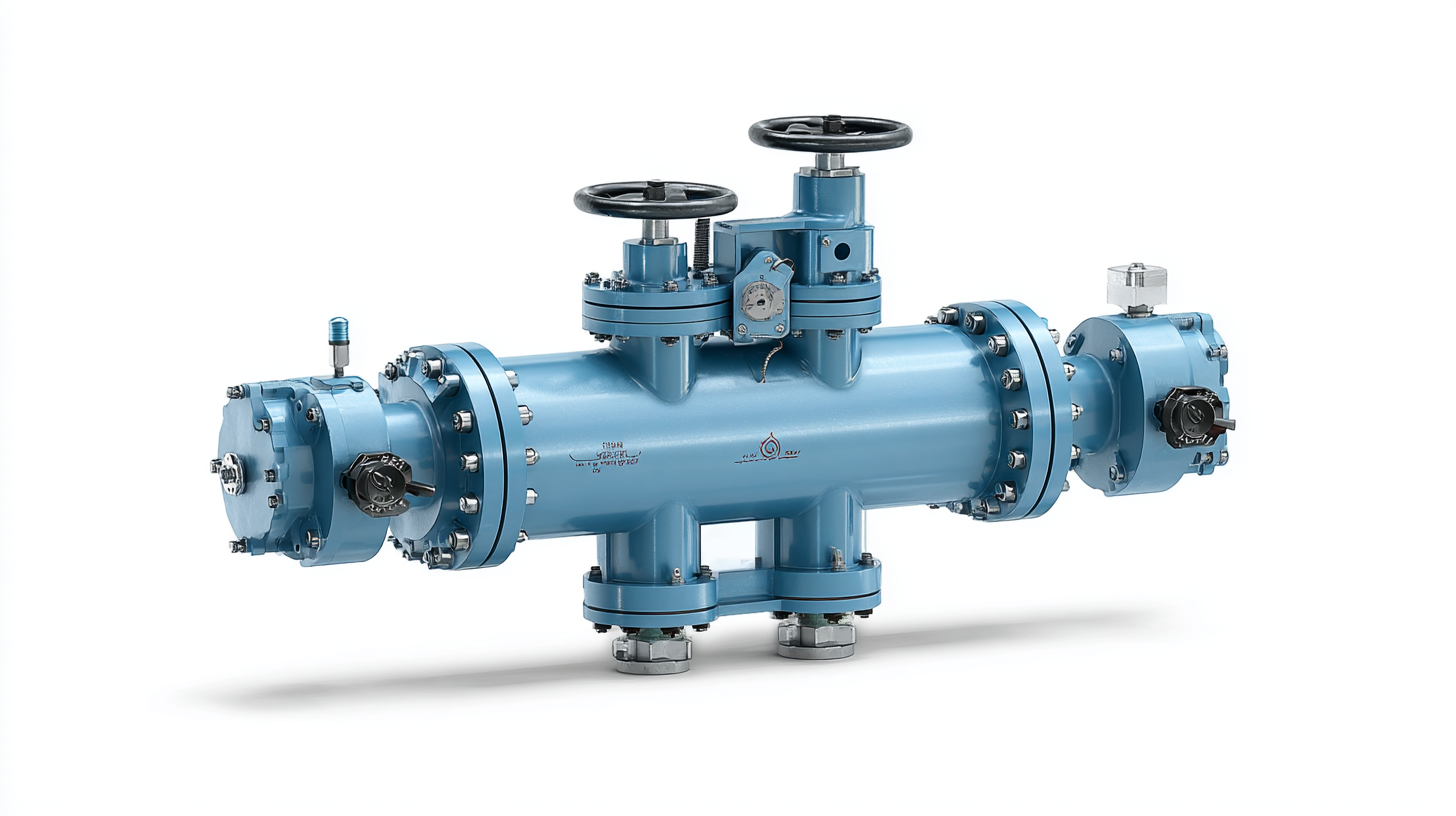

When it comes to ensuring the safety and efficiency of various industrial systems, the importance of a low pressure relief valve cannot be overstated. These critical components are designed to prevent excessive pressure buildup by releasing excess pressure from systems that operate under low pressure conditions. Understanding the functionality and selection of the right low pressure relief valve is essential for maintaining operational integrity and safeguarding both equipment and personnel.

In this guide, we will delve into the top 10 low pressure relief valves available in 2025, highlighting their features, benefits, and applications. Whether you are looking to optimize safety in a manufacturing plant, chemical processing facility, or any other setting where low pressure systems are employed, choosing the appropriate low pressure relief valve can make all the difference. With a focus on essential criteria such as durability, reliability, and performance, this comprehensive overview will serve as a valuable resource for industry professionals aiming to enhance safety standards in their operations.

By the end of this article, readers will have a better understanding of how to select and implement the best low pressure relief valve for their unique needs, ensuring a safer working environment and improved operational efficiency.

Top 10 Low Pressure Relief Valves for Industrial Applications in 2025

In 2025, the demand for low-pressure relief valves in industrial applications continues to rise, driven by the need for enhanced safety and operational efficiency. These valves play a crucial role in protecting equipment and personnel by alleviating excess pressure from various systems, thereby preventing potentially hazardous situations. The top ten low-pressure relief valves for this year have been meticulously selected based on their reliability, durability, and compliance with industrial standards.

Among these top contenders, features such as corrosion resistance, precise pressure settings, and easy maintenance are highlighted. Industries ranging from chemical processing to food production require tailored solutions that can handle specific challenges associated with low-pressure systems. Innovations in valve design have also improved response times and reduced leakage rates, making them essential components in safeguarding operational integrity. As industries strive for optimal safety, investing in high-quality low-pressure relief valves becomes a fundamental aspect of their safety protocols in 2025.

Key Features to Consider in Low Pressure Relief Valve Selection

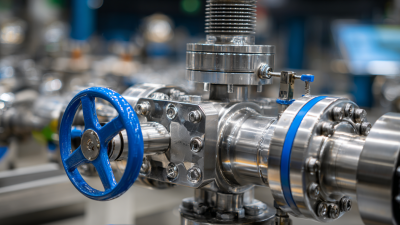

When selecting a low pressure relief valve, several key features should be considered to ensure optimal safety and functionality. First and foremost, the set pressure range is critical; the valve must be calibrated to open at a precise pressure level to prevent system overpressure. Therefore, understanding the operational parameters of your system is essential. Additionally, the materials of construction play a vital role in the valve's performance and longevity. Valves should be made of corrosion-resistant materials suitable for the media they will handle, ensuring reliability over time.

Another important consideration is the valve size and connection type, which must be compatible with your existing system. Proper sizing not only ensures that the valve can handle the expected flow rates but also minimizes the risk of failure. Furthermore, look for valves with features such as blow-off indicators and easy maintenance access, which can provide additional safety and convenience in operation. Ultimately, selecting the right low pressure relief valve involves a comprehensive understanding of these features to safeguard your system effectively.

2025 Top 10 Low Pressure Relief Valves - Key Features Comparison

Comparison of Material Types in Low Pressure Relief Valves

When selecting low pressure relief valves, the material type plays a crucial role in determining performance, durability, and safety. Common materials used in these valves include brass, stainless steel, and thermoplastics, each offering distinct advantages suited to different applications. Brass is favored for its affordability and corrosion resistance in lower pressure environments, making it ideal for many commercial settings. However, it may not withstand more aggressive chemical exposures, which is where stainless steel shines due to its superior toughness and resistance to corrosion. This makes stainless steel valves particularly suitable for demanding applications, such as those involving harsh chemicals or higher temperatures.

Thermoplastic materials, on the other hand, are increasingly being utilized in low pressure relief valves for their lightweight properties and exceptional chemical resistance. Valves made from thermoplastics can often handle corrosive substances very effectively, ensuring both longevity and reliability. Additionally, the ability to mold these materials into intricate designs allows for customization that can enhance performance in specific conditions. By considering these material types, manufacturers can ensure that low pressure relief valves not only meet operational requirements but also contribute to overall safety and efficiency in various industries.

Maintaining Safety Standards: Testing and Certification for Relief Valves

In the realm of industrial safety, relief valves play a crucial role in preventing excessive pressure buildup in systems. To ensure these vital components perform optimally, rigorous testing and certification processes are essential. Regulatory bodies set stringent standards that manufacturers must meet to guarantee reliability and safety in high-pressure environments. Testing typically involves simulating various operational conditions to assess the valve's performance, responsiveness, and durability. Only those valves that pass these thorough evaluations earn the requisite certifications, which serve as a benchmark for quality and safety.

Certification not only instills confidence in the operational capabilities of relief valves but also fosters a culture of compliance within industries. Companies are increasingly prioritizing the procurement of certified relief valves, understanding that proper maintenance of safety standards can minimize risks and mitigate potential hazards. Regular audits and inspections further reinforce the importance of these certifications, ensuring that all installed valves remain in peak condition throughout their operational lifespan. This commitment to safety, backed by thorough testing and certification, ultimately protects both personnel and equipment from the dangers associated with high-pressure systems.

Future Innovations in Low Pressure Relief Valve Technology and Design

The future of low pressure relief valve technology and design is on the brink of transformation. As industries continuously strive for enhanced safety measures, innovations such as smart pressure relief valves are gaining traction. These advanced devices can integrate IoT technology, allowing for real-time monitoring and data analytics. This capability ensures operators can detect potential failures before they escalate, significantly reducing risks and enhancing operational safety.

Tip: When considering upgrading to smart valves, assess your current system's compatibility. A seamless integration can maximize efficiency and safety.

Moreover, the introduction of more durable materials and corrosion-resistant coatings is set to improve the lifespan and reliability of these valves. Innovations in design also focus on reducing maintenance needs while ensuring compliance with stringent safety regulations. Manufacturers are increasingly prioritizing user-friendly features, making it easier for operators to monitor and manage pressure levels.

Tip: Regularly schedule training for your staff to familiarize them with new technologies and best practices in maintenance for optimal performance.

Related Posts

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

Understanding the Importance of Safety Valves in Industrial Applications

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance