Top 5 Temperature and Pressure Relief Valve Solutions Explained?

Temperature and pressure relief valves are critical components in various industries. Their primary function is to enhance safety by preventing dangerous overpressure situations. When a system exceeds its safe limits, these valves activate, releasing excess pressure or temperature. This process can prevent catastrophic failures.

However, not all temperature and pressure relief valve solutions are equal. Some are more efficient and reliable than others. Businesses must carefully evaluate their options. Finding the right valve can be a daunting task. Some solutions may look effective on paper but fall short during real-world applications.

In this article, we will explore the top five solutions available today. We’ll dive into their unique features and potential drawbacks. Understanding each option can guide you in making informed decisions. Your choice could determine the safety and efficiency of your systems. Ultimately, it's crucial to reflect on what works best for your needs.

Understanding Temperature and Pressure Relief Valves: An Overview

Temperature and pressure relief valves (TPR valves) play a crucial role in various applications. They ensure the safety of systems by preventing excessive pressure buildup. When systems heat, pressure rises. TPR valves open, releasing steam or fluids to maintain safe levels. Understanding these valves is vital for any engineering or maintenance professional.

Choosing the right TPR valve can be challenging. Factors like size, temperature rating, and application type matter greatly. Consider the specific environment where the valve will be used. For example, a valve for a hot water system needs a different rating than one for steam systems. Research is key.

Tips: Always check the manufacturer's guidelines. Installing the wrong valve can lead to failures. Regular maintenance is imperative too. Inspect valves routinely for wear and corrosion. Identify any leakage, as this can compromise safety. Being proactive helps you stay ahead of potential issues, ensuring your systems remain reliable. Understanding your equipment can make a significant difference.

Key Features of Effective Relief Valves for Safety Applications

When discussing safety applications, temperature and pressure relief valves play a critical role. These valves prevent dangerous conditions by automatically releasing excess pressure or temperature. Their design focuses heavily on reliability and quick response. A key feature is the set pressure. This pressure must be clearly defined to ensure proper functioning. It’s essential to have a well-calibrated valve. If not, it could result in catastrophic failures.

Another important detail is the material of the valve. High-quality materials withstand extreme conditions. They resist corrosion and ensure durability. The valve's size matters too. An improperly sized valve may fail to release the necessary pressure. This could lead to mechanical damage or worse. Regular maintenance is crucial. Neglect can lead to deterioration.

Moreover, user education is vital. Operators must understand how these valves operate. Wrong usage may compromise safety. It's important to periodically evaluate the performance of these valves. This reflection leads to improved safety practices and potentially better designs in the future. Investing in training and regular checks can make a big difference.

Comparison of Different Types of Temperature and Pressure Relief Valves

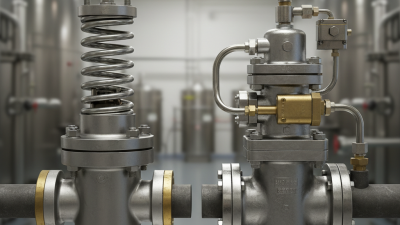

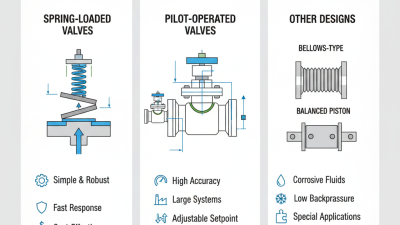

When it comes to temperature and pressure relief valves, there are several types to consider. Each type has unique features that cater to specific applications. For instance, spring-loaded valves are widely used due to their simplicity and effectiveness. They release excess pressure by lifting a disc or poppet from its seat.

On the other hand, pilot-operated valves are more complex. They use a pilot valve to control the flow, which makes them suitable for high-pressure systems. They tend to have better sealing capabilities and can handle larger volumes. Still, they can be a bit harder to maintain.

Tips: When selecting a valve, think about the application. Every situation is different. Ensure to measure the pressure and temperature in your system accurately. Proper calibration is crucial. Don't overlook the need for regular maintenance. A little vigilance can prevent bigger problems down the road.

Diaphragm relief valves, another option, are effective for corrosive or hazardous fluids. They provide a tight seal and minimize leakage risks. However, they may not perform well in high-temperature environments. It's vital to evaluate the fluid characteristics before making a decision.

Tips: Check manufacturer guidelines for fluid compatibility. Not all valves are created equal. Sometimes, you may need a custom solution. It’s okay to ask for help from industry experts. They can guide you through the selection process.

Installation Best Practices for Relief Valve Solutions

Proper installation of temperature and pressure relief valves is crucial to ensure safety and reliability. Many professionals overlook the importance of following manufacturers' guidelines. In fact, research shows that improper installation can lead to a 25% increase in equipment failures. This is concerning when you consider that relief valves protect against catastrophic failures in many industrial systems.

One common mistake is not accounting for the system's specific pressure and temperature requirements. Using the wrong valve can result in inadequate protection. For example, a valve that opens too late may allow dangerous pressure to build. Moreover, misaligned piping can cause leaks, reducing the valve's effectiveness. It's essential for technicians to verify alignment during installation. Regular inspection post-installation is also necessary, as valves can degrade over time.

Additionally, the wrong materials can compromise the integrity of a relief valve. Using incompatible materials can lead to corrosion or other failures. Yet, many facilities still choose cost over quality. A report by the National Institute of Standards and Technology indicates that prioritizing reliable materials can reduce long-term costs by nearly 40%. Installation practices must prioritize thorough checks and use the right components to ensure consistent performance.

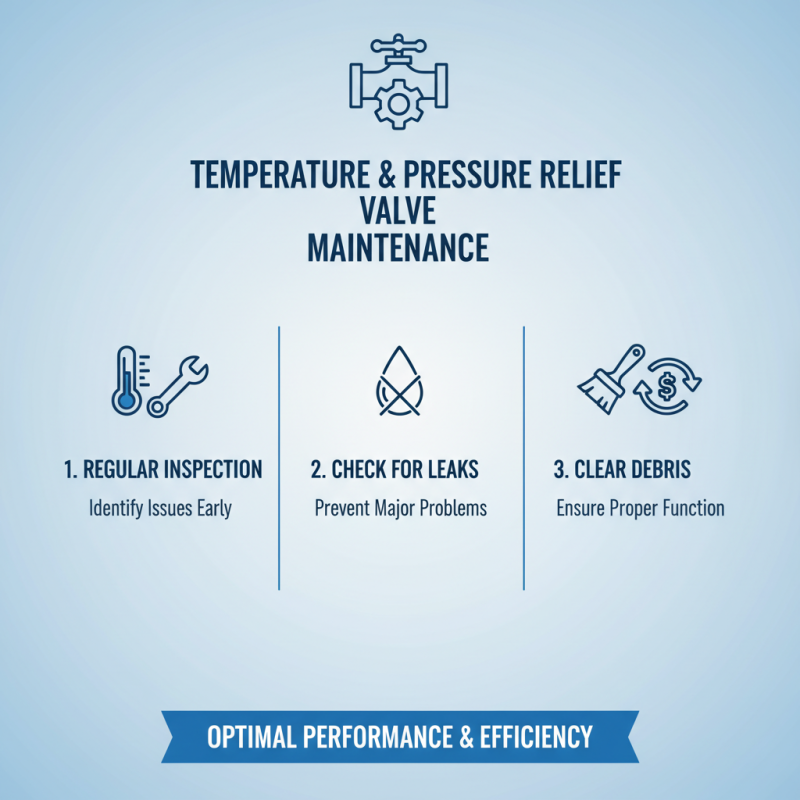

Maintenance Tips to Ensure Optimal Performance of Relief Valves

Maintaining temperature and pressure relief valves is essential for optimal performance. Regular inspection helps identify potential issues before they escalate. Checking for leaks is crucial; even small ones can lead to significant problems. Ensuring the valve is free from debris or buildup is equally important. This simple step can prevent improper function and improve efficiency.

When performing maintenance, adhere to a schedule. It’s vital to document all inspections and repairs. If a valve exhibits signs of wear, it may need replacement. Keeping spare parts on hand can save time during emergencies. Remember, overlooking minor details can lead to failures that disrupt operations.

Monitoring the valve’s performance is key. Listen for unusual sounds, such as rattling. These could indicate a malfunction. Additionally, maintain proper pressure settings. Regularly calibrating the system can help prevent unexpected pressures. These small adjustments could have a big impact on overall safety.

Related Posts

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Top 2 Pressure Relief Valve Types You Should Know?

-

Why is a Pressure Relief Valve Essential for Safety and Performance?

-

Top 10 Benefits of Using Pressure Vacuum Relief Valves for Your Industry

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?