Top 10 Inline Pressure Relief Valves You Should Consider for Your System

In the world of industrial systems, the role of an inline pressure relief valve cannot be overstated. These critical components ensure the safety and efficiency of operations by protecting equipment from excessive pressure variations. As industry expert Dr. Emily Carter, a renowned engineer at the Flow Control Institute, aptly states, "Choosing the right inline pressure relief valve is essential for maintaining system integrity and preventing catastrophic failures."

In this article, we delve into the top 10 inline pressure relief valves you should consider for your system. Each valve has its unique features and advantages, catering to varying applications and requirements. Selecting the optimal valve not only enhances the performance of your system but also ensures compliance with safety regulations and standards.

As we explore these top choices, it’s important to understand the factors that influence their effectiveness, such as pressure settings, flow rates, and material compatibility. By the end of this article, you’ll be well-equipped to make an informed decision that will bolster the reliability and safety of your operations, while effectively managing pressure within your system.

Best Practices for Selecting Inline Pressure Relief Valves for Enhanced Safety

When selecting inline pressure relief valves (PRVs), prioritizing safety and reliability is paramount. According to the American Society of Mechanical Engineers (ASME), approximately 90% of industrial system failures can be traced back to valve malfunctions. This underscores the importance of choosing high-quality PRVs that meet stringent industry standards. It’s essential to consider factors such as the valve's set pressure, flow capacity, and material compatibility with the fluids being handled, as these can significantly affect the performance and longevity of the system.

Additionally, industry reports suggest that implementing best practices in valve selection can enhance operational efficiency by up to 25%. Engineers should assess the specific requirements of their systems, including pressure fluctuations and temperature ranges, to determine the appropriate type of valve. Furthermore, regular maintenance schedules and performance testing are crucial, as the reliability of inline PRVs is not only about the initial selection but also about ongoing care and monitoring to prevent system failures and ensure regulatory compliance.

Key Features to Look for in High-Performance Inline Pressure Relief Valves

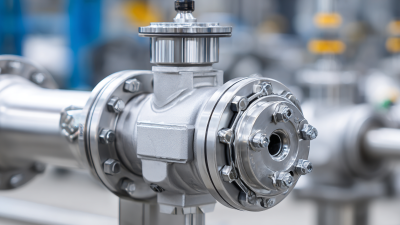

When selecting inline pressure relief valves for your system, it's essential to focus on key features that ensure optimal performance and reliability. One primary consideration is the valve's set pressure range, which should be adjustable to accommodate varying operating conditions. An effective valve must be able to respond quickly to pressure fluctuations, preventing potential system failures. Additionally, look for valves constructed from durable materials that can withstand harsh environments and corrosive substances, thereby extending their lifespan.

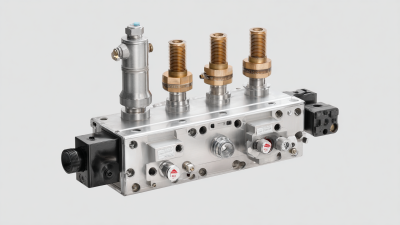

Another critical feature is the valve's flow capacity, which directly impacts efficiency in pressure release. High-performance valves often come equipped with a robust spring mechanism and streamlined design that facilitate swift and unobstructed flow. Lastly, consider the ease of maintenance and installation. Valves designed with user-friendly features, such as accessible adjustment points and clear markings, make both routine checks and emergency repairs considerably straightforward, ultimately contributing to system reliability and reducing downtime.

Comparative Analysis of the Top Inline Pressure Relief Valves for 2025

When selecting inline pressure relief valves for 2025, it’s essential to analyze the various options available in the market. Leading manufacturers have developed valves that not only offer reliability but also cater to specific industrial needs. The comparative analysis highlights key features such as flow rate, pressure settings, and materials used in construction. These factors play a crucial role in determining how well a valve will perform under varying conditions.

Moreover, user feedback and industry certifications should be taken into account when assessing the best options. Some models stand out due to their innovative designs that enhance performance and safety. For instance, valves equipped with advanced sealing technologies tend to minimize leakage risks, while those with modular designs facilitate easier maintenance. By focusing on these elements, engineers and procurement teams can make informed decisions, ensuring that the inline pressure relief valves selected will optimize safety and efficiency in their systems.

Top 10 Inline Pressure Relief Valves for 2025

This chart represents a comparative analysis of the top inline pressure relief valves based on their pressure setting range (psi) and flow capacity (GPM). The data illustrates the essential specifications that should be considered for each valve in your system.

Customer Reviews: Real-World Performance of 2025's Top Inline Pressure Relief Valves

Customer reviews play a crucial role in evaluating the real-world performance of inline pressure relief valves. As we look into 2025's top selections, feedback from users highlights how well these valves function under various operating conditions. Many customers report that these valves offer consistent performance, effectively maintaining the desired pressure levels in their systems. Users often note that the reliability of these valves in critical applications is invaluable, reducing the risks of system failures and operational downtime.

Moreover, some reviews emphasize the durability and construction quality of these top-rated valves. Customers appreciate valves that withstand harsh environments and sustained pressure fluctuations without compromising on safety or efficiency. Many highlight ease of installation and maintenance as key factors in their satisfaction, as these features contribute to smoother operations and cost savings in the long run.

The insights from actual users provide a valuable perspective, illuminating the strengths and any potential weaknesses of these inline pressure relief valves, thereby guiding potential buyers in making informed decisions.

Future Trends in Inline Pressure Relief Valve Technology for Enhanced Efficiency

The future of inline pressure relief valve technology is evolving rapidly, driven by advancements in artificial intelligence and operational intelligence. AI integration can significantly enhance predictive maintenance and operational efficiency, allowing systems to adapt proactively to changing pressures and conditions. This smart monitoring capability not only reduces downtime but also minimizes the risk of system failures, promoting safer operations in various industries.

Sustainability is another key trend shaping the development of inline pressure relief valves. With increasing emphasis on sustainable water treatment solutions, manufacturers are innovating to develop valves that are more efficient in resource usage. Furthermore, the move towards decentralized infrastructure supports localized solutions that can effectively manage resources while preventing issues such as flooding. As industries strive to meet environmental regulations and enhance resilience, the role of advanced pressure relief valves will become increasingly vital in ensuring system reliability and performance.

Related Posts

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Understanding Hydraulic Relief Valves: Essential Insights for Efficient Fluid Control Systems

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency