Top 2 Pressure Relief Valve Types You Should Know?

Pressure relief valves play a crucial role in various systems. They help maintain safe operating conditions. Knowing about the 2 pressure relief valve types can enhance your understanding of their function.

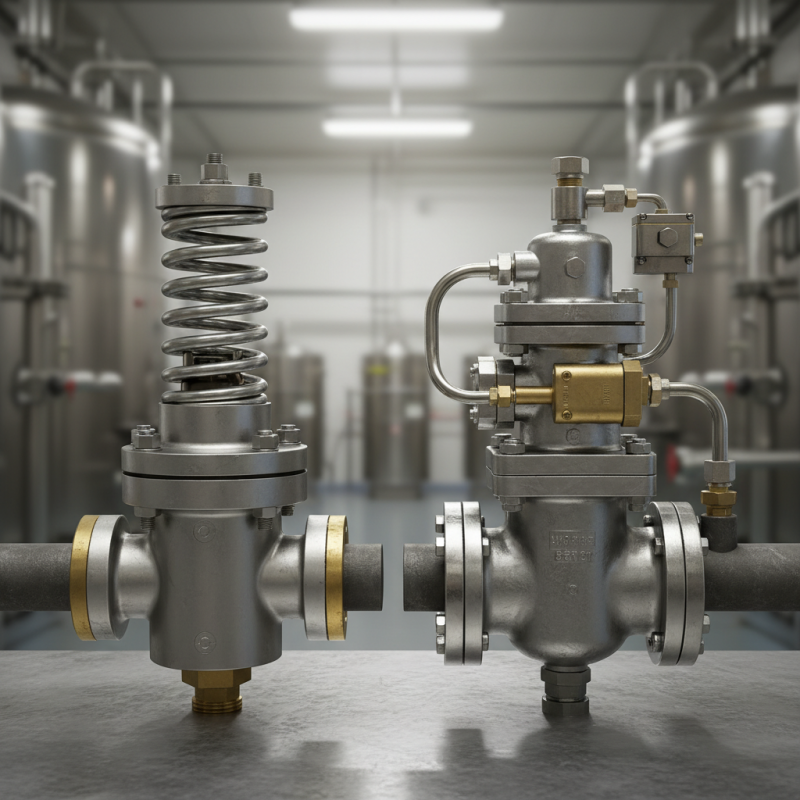

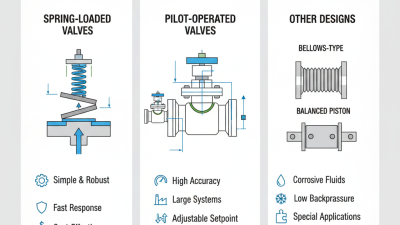

The two main types are spring-loaded and pilot-operated valves. Spring-loaded valves are simple and efficient. They rely on a spring to open at a specific pressure. Their design is straightforward, which makes them easy to install but may lead to occasional leaks over time.

On the other hand, pilot-operated valves offer more control. They use a small pilot valve to manage the larger main valve. This results in better performance but can be more complex. Understanding these differences is key. It's not just about knowing the types but also about recognizing their limitations and applications in real-world scenarios.

Understanding Pressure Relief Valves: An Overview

Pressure relief valves (PRVs) are essential in various industries. They prevent dangerous pressure buildup in systems. Understanding their function helps ensure safety and efficiency. According to recent industry reports, PRVs can mitigate risks in operations by reducing equipment failure by approximately 15%. Knowing about PRVs is vital for safe system management.

There are two main types of PRVs: direct-acting and pilot-operated. Direct-acting valves are simple and efficient, suitable for lower pressures. Pilot-operated valves, however, handle higher pressures better. These valves use a smaller valve, the pilot, to control a larger valve. This dual action improves precision.

**Tip:** Regular maintenance and testing of PRVs are crucial. Neglect can lead to valve failure. Data shows that regular checks can increase lifespan by 30%.

Incorporating pressure relief systems is not just about equipment. It’s about understanding the risks involved. Many companies overlook the importance of proper valve selection. This oversight can result in costly failures. Ensure your team is properly trained on these systems. Keep records of valve performance to identify potential issues early.

Types of Pressure Relief Valves: A Closer Look

Pressure relief valves are crucial in managing system pressure. They prevent overpressure, protecting equipment and personnel. Understanding their types can help in selecting the right one.

Two common types are spring-loaded and pilot-operated valves. Spring-loaded valves have a simple mechanism. They open when pressure exceeds a certain level. However, they can be sensitive to fluctuations, which may lead to inconsistencies. On the other hand, pilot-operated valves are more complex. They use a pilot valve to control the larger valve's opening. This design offers better stability and is less prone to chatter. Yet, it comes with higher costs and maintenance needs.

Each type has pros and cons. Choosing the right valve depends on system requirements and operating conditions. Sometimes, the choice may lead to regrets. Maybe an option seems perfect but doesn't fit real-life scenarios. Careful evaluation is essential.

Features and Benefits of Spring-Loaded Relief Valves

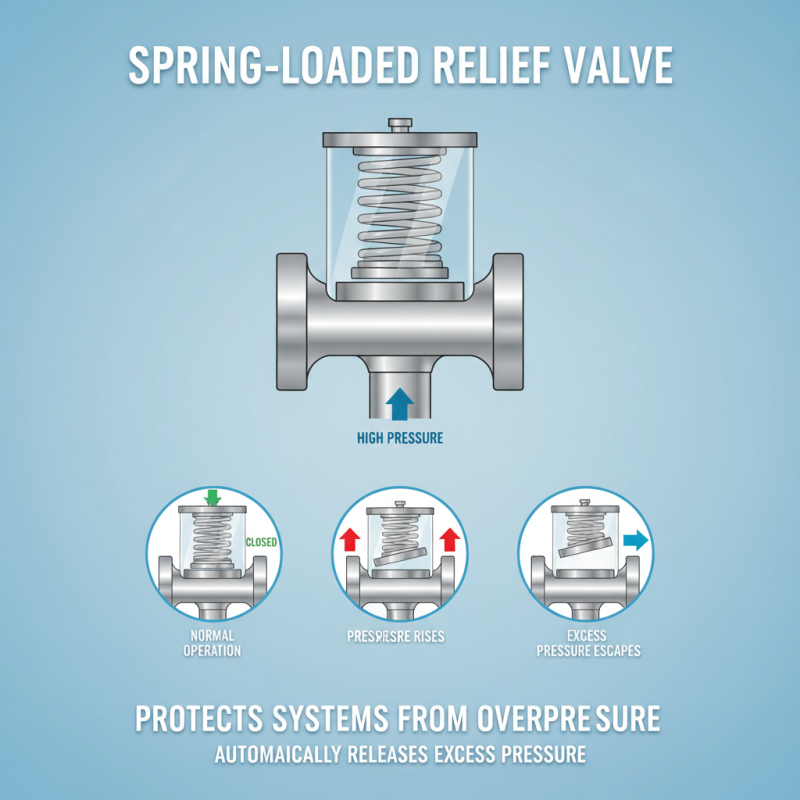

Spring-loaded relief valves are crucial in various industries. They help protect systems from overpressure. These valves automatically open when pressure exceeds a preset level. Their design is straightforward, yet effective. They consist of a spring, a valve seat, and a disk. When pressure rises too high, the spring compresses. This action allows the disk to lift, releasing excess pressure.

The benefits of spring-loaded relief valves are numerous. They enhance safety by preventing system failures. In process industries, this is particularly vital. Keeping machinery and personnel safe is a priority. These valves also reduce downtime. Regular maintenance is easier due to their simple construction. However, some users struggle with calibration. Getting the right pressure setting can be tricky. It often requires experience and precision.

Another aspect to consider is material choice. Different environments necessitate different materials. Corrosion resistance is a key factor. Incorrect choices can lead to valve failure. Users should evaluate their specific needs and conditions. Making overlooking these details can be costly. A thoughtful approach to choosing spring-loaded relief valves ensures better performance and longevity.

Exploring Pilot-Operated Pressure Relief Valves

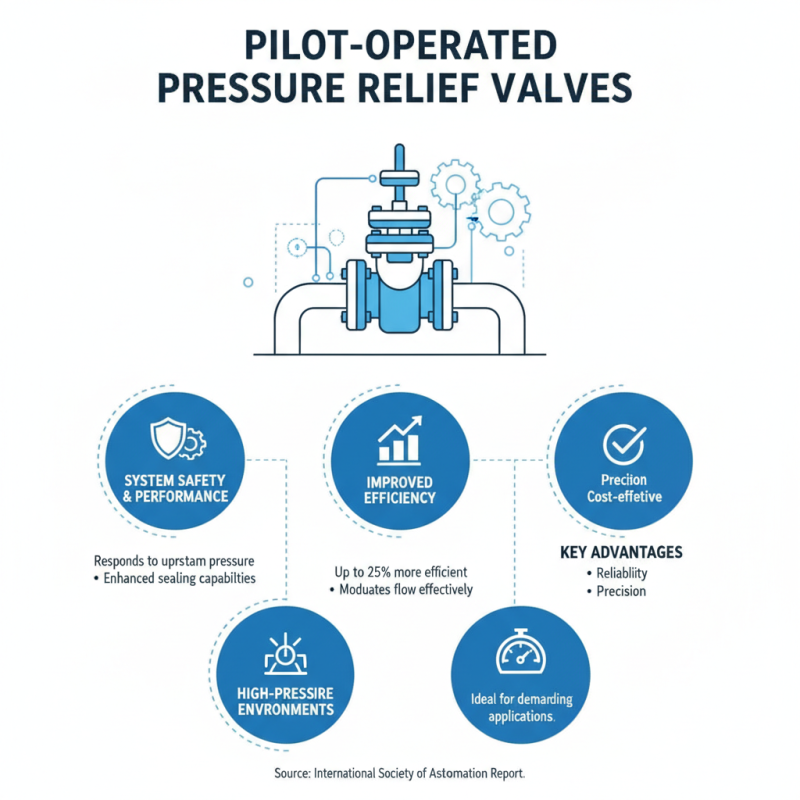

Pilot-operated pressure relief valves are crucial for maintaining system safety and performance. These valves respond to upstream pressure fluctuations and can enhance sealing capabilities compared to conventional valves. According to a report by the International Society of Automation, pilot-operated valves can improve efficiency by up to 25% in some applications. This efficiency stems from their ability to modulate flow effectively, making them ideal for high-pressure environments.

One significant aspect of pilot-operated pressure relief valves is their design complexity. The pilot mechanism can sometimes lead to responsiveness issues, especially in extreme conditions. For example, a study published in the Journal of Pressure Vessel Technology highlighted that improper sizing can lead to failure in opening or closing the valve. This inefficiency raises concerns over system integrity and operational costs. Such vulnerabilities remind us that even advanced technology can falter under pressure.

Additionally, maintenance practices are vital for the reliability of these valves. Regular checks on the pilot control system can prevent potential failures. Yet, many operators overlook such maintenance, which can lead to catastrophic events. Industry data shows that nearly 30% of valve failures are linked to poor maintenance practices. This statistic underscores the need for operators to be vigilant and proactive in addressing these issues.

Applications and Best Practices for Pressure Relief Valves

Pressure relief valves (PRVs) are crucial in various industries. They prevent equipment failure by controlling excess pressure. Understanding their applications can enhance safety in operation. Two common types are spring-loaded and pilot-operated valves. Each has unique applications and best practices.

Spring-loaded PRVs are simple and widely used. They automatically open when pressure exceeds a set limit. These valves are common in water systems and air compressors. They work well in low-pressure environments. However, they can be sensitive to system vibrations. This can lead to premature opening or failure. Regular checks are essential.

Pilot-operated PRVs offer more precise control. They are ideal for high-pressure systems. The pilot valve opens at a set pressure, allowing the main valve to open smoothly. This type is often seen in oil and gas applications. However, they can be complex, leading to maintenance challenges. Proper installation and calibration are critical to their performance. Understanding these applications helps prevent mishaps.

Related Posts

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

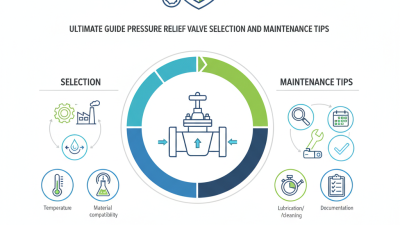

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips