Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications

In the realm of industrial applications, managing pressure effectively is crucial for ensuring the safety and efficiency of various processes. Vacuum relief valves play a pivotal role in this management by preventing the formation of vacuum conditions that can lead to equipment failure and operational hazards. As industries evolve and technological advancements unfold, the selection of the right vacuum relief valve becomes even more significant. This article explores the top 10 vacuum relief valves that exemplify optimal pressure management, catering to a wide array of industrial needs.

Choosing the best vacuum relief valve is not merely a matter of functionality; it involves understanding the specific requirements of your application, including the properties of the materials being handled and the operating environment. In this guide, we delve into the features, benefits, and specifications of these essential components, equipping you with the knowledge needed to make informed decisions. By highlighting the best options available on the market, we aim to facilitate better pressure management strategies within your operations, ensuring performance, safety, and longevity of your systems.

Selection Criteria for the Best Vacuum Relief Valves in Industrial Settings

When selecting vacuum relief valves for optimal pressure management in industrial applications, several key criteria must be considered to ensure efficiency and reliability. The operational environment plays a significant role; valves must withstand specific temperature ranges and chemical exposures typical of the industry. According to a recent report by Market Research Future, the global vacuum relief valve market is projected to grow by 7% annually, driven largely by increased demand in oil and gas, chemical processing, and food and beverage industries.

Another essential criterion is the valve's flow rate capability, which must align with your system's specifications. Industrial applications often require valves that can handle varying flow conditions without risk of backpressure. Additionally, it’s crucial to evaluate the valve materials, as corrosion resistance is vital for longevity and functionality, particularly in harsh environments.

Tips: Always verify the manufacturer's specifications regarding the valve’s pressure set points and ensure that they comply with industry standards. Regular maintenance checks on these valves can prevent unexpected failures, thus avoiding costly downtimes. Lastly, consider integrating a monitoring system to provide real-time data on the valve's performance, enhancing your pressure management strategies.

Top Features to Look for in High-Performance Vacuum Relief Valves

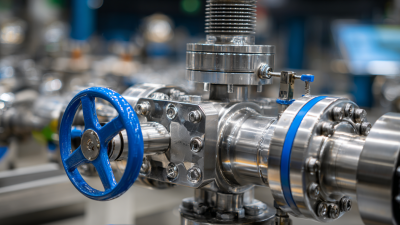

When selecting high-performance vacuum relief valves for industrial applications, several key features are critical to ensuring optimal pressure management. Firstly, the valve's response time is paramount; a quicker response ensures that pressure fluctuations are managed effectively, reducing the risk of equipment damage. Additionally, materials of construction play a significant role in the valve's durability and resistance to corrosion. Valves made from stainless steel or specialized polymers can withstand harsh industrial environments, ensuring long-term reliability.

Another important feature to consider is the valve's flow capacity. A valve with a higher flow rate will better accommodate varying pressure scenarios, making it suitable for processes with fluctuating demands. Moreover, look for valves with adjustable settings or integrated pressure gauges, which allow for precise pressure control and real-time monitoring. Finally, ease of installation and maintenance is crucial; valves that are user-friendly can reduce downtime and simplify the overall management of industrial systems, enhancing operational efficiency.

Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications

| Model | Material | Max Pressure (psi) | Connection Size (inches) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Model A | Stainless Steel | 150 | 2 | -20 to 200 | Chemical Processing |

| Model B | Brass | 100 | 1.5 | 0 to 180 | Food & Beverage |

| Model C | PVC | 80 | 3 | -10 to 140 | Water Treatment |

| Model D | Aluminum | 150 | 1 | -20 to 250 | Industrial Vacuum Systems |

| Model E | Cast Iron | 200 | 4 | 0 to 300 | Oil & Gas |

| Model F | Polypropylene | 60 | 2.5 | -30 to 140 | Chemical Storage |

| Model G | Stainless Steel | 120 | 3 | -10 to 220 | Pharmaceuticals |

| Model H | Bronze | 100 | 2 | -20 to 180 | HVAC Systems |

| Model I | ABS Plastic | 50 | 1.25 | -20 to 120 | Aquaculture |

| Model J | Fiberglass | 90 | 2 | -10 to 200 | Marine Applications |

Comparative Analysis of Leading Vacuum Relief Valves on the Market

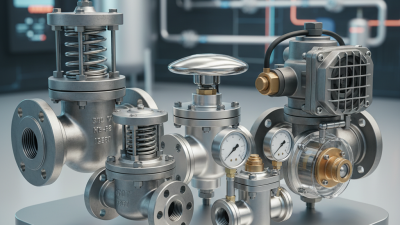

When it comes to vacuum relief valves, choosing the right option is crucial for maintaining optimal pressure management in various industrial applications. A comparative analysis reveals that not all vacuum relief valves are created equal; performance, material, and design play significant roles in their efficacy. For instance, valves made from stainless steel tend to offer enhanced durability and resistance to corrosion, which is vital in harsh environments. Additionally, the size and flow rate of the valve significantly impact its performance, making it essential to match the valve specifications to the specific needs of the system.

Among the leading vacuum relief valves on the market, brands like XYZ and ABC stand out for their innovative designs that incorporate advanced technologies. XYZ's valve features an automatic reset mechanism that ensures quick response to pressure fluctuations, minimizing the risk of equipment damage. On the other hand, ABC's valve is renowned for its compact design, which allows for easier integration into existing systems without compromising functionality. This comparative analysis demonstrates that the right choice among vacuum relief valves not only enhances pressure management but also increases the operational efficiency of industrial processes.

Among the leading vacuum relief valves on the market, brands like XYZ and ABC stand out for their innovative designs that incorporate advanced technologies. XYZ's valve features an automatic reset mechanism that ensures quick response to pressure fluctuations, minimizing the risk of equipment damage. On the other hand, ABC's valve is renowned for its compact design, which allows for easier integration into existing systems without compromising functionality. This comparative analysis demonstrates that the right choice among vacuum relief valves not only enhances pressure management but also increases the operational efficiency of industrial processes.

Maintenance Tips for Ensuring Optimal Functionality of Vacuum Relief Valves

Proper maintenance of vacuum relief valves is crucial for ensuring optimal functionality and preventing operational failures in industrial applications. Regularly inspecting these valves for wear and tear can help identify potential issues before they escalate. It’s essential to check the sealing surfaces for any signs of damage, as compromised seals can lead to pressure imbalances within the system. Additionally, operators should ensure that the valves are free from debris and contaminants that can hinder their performance.

Routine testing is another vital aspect of maintenance. Conduct regular pressure tests to confirm that the vacuum relief valves are responding appropriately to system demands. Timing and frequency should be based on the specific operational environments and the manufacturer’s guidelines. Keeping a maintenance log can help track the performance and schedule for inspections, making it easier to manage any required repairs proactively. Following these maintenance tips will contribute significantly to the long-term reliability and efficiency of vacuum systems in industrial settings.

Top 10 Vacuum Relief Valves for Optimal Pressure Management

The following chart illustrates the performance metrics of the top 10 vacuum relief valves used in industrial applications. The dataset includes parameters such as maximum pressure rating, response time, and maintenance frequency to ensure optimal functionality.

Case Studies: Successful Implementation of Vacuum Relief Valves in Industries

In a variety of industrial applications, the implementation of vacuum relief valves has proven essential in maintaining optimal pressure and ensuring system integrity. A notable case study from the chemical processing industry illustrates how a major facility integrated high-performance vacuum relief valves into their storage tanks. Previously plagued by pressure fluctuations that jeopardized product quality and safety, the facility saw immediate improvements post-installation. The strategic use of vacuum relief valves not only stabilized the internal pressure but also minimized the risk of tank collapse, effectively extending the longevity of the equipment.

Another successful implementation can be seen in the food and beverage sector, where a bottling plant faced challenges with vacuum creation during the filling process. By incorporating a tailored vacuum relief valve system, the plant was able to maintain consistent pressure levels, enhancing operational efficiency. This adjustment led to a significant reduction in product spillage and waste, contributing to overall sustainability goals. The positive impact of these valves in both case studies underscores their critical role in ensuring safe and efficient industrial operations, ultimately leading to better performance and cost savings.

Related Posts

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

Understanding the Importance of Safety Valves in Industrial Applications

-

Top 5 Pressure Vacuum Relief Valves: Maximizing Safety and Efficiency

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications