Essential Tips for Understanding Vacuum Relief Valve Functionality and Maintenance

In the world of industrial systems, understanding the functionality and maintenance of a vacuum relief valve is crucial for ensuring operational efficiency and safety. According to Dr. John Smith, a leading expert in fluid dynamics and vacuum systems, “A properly functioning vacuum relief valve is essential to prevent system failures and maintain stability during pressure fluctuations.” This statement highlights the importance of this often-overlooked component in various applications, from chemical processing to food manufacturing.

Vacuum relief valves are vital in protecting equipment from the potentially damaging effects of vacuum conditions. They function by allowing air to enter a system when a vacuum is created, thereby preventing the collapse of storage tanks or pipelines. Without proper maintenance, these valves can become clogged or malfunction, leading to catastrophic failures.

This article will delve into essential tips for understanding the functionality and maintenance of vacuum relief valves, ensuring operators can effectively safeguard their systems against unwanted vacuum conditions. Whether you are a seasoned engineer or a newcomer to the industry, grasping the principles of these valves is key to enhancing safety and performance in your operations.

Understanding the Basics of Vacuum Relief Valves

Vacuum relief valves are crucial components in various systems where maintaining atmospheric pressure is essential. These valves operate by allowing air or gas to enter a vessel when the internal pressure drops below a designated threshold. This functionality prevents the formation of a vacuum, which can lead to structural damage or collapse of the vessel. Understanding their operational principles is vital for ensuring safety and efficiency in applications ranging from storage tanks to processing equipment.

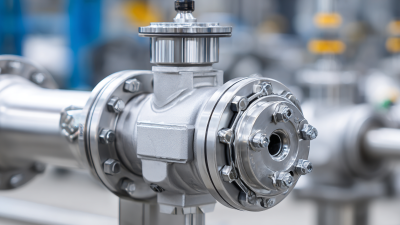

The design of vacuum relief valves typically features a spring-loaded mechanism that opens at a specific negative pressure. When the internal pressure decreases, the valve automatically opens, equalizing the pressure by permitting air in. Proper sizing and placement of these valves are critical, as they must respond quickly to prevent excessive vacuum conditions. Regular maintenance is essential to ensure their longevity and reliability; operators should inspect the valves for wear and blockages and perform operational tests to confirm that they function correctly. Understanding these fundamentals is key to optimizing the performance of systems reliant on vacuum relief valves.

Essential Tips for Understanding Vacuum Relief Valve Functionality and Maintenance

| Aspect | Details |

|---|---|

| Functionality | Prevents vacuum formation in tanks and piping systems. |

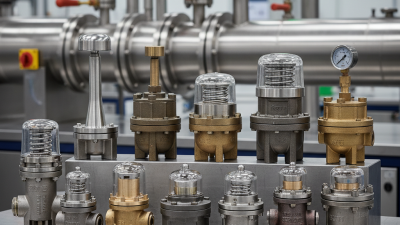

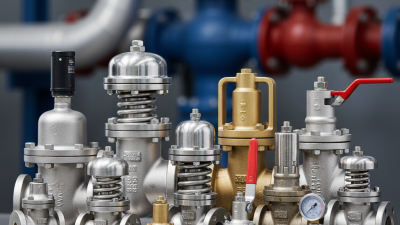

| Types | Spring-loaded, weight-loaded, and pilot-operated designs. |

| Materials | Typically made from stainless steel, brass, or plastic. |

| Application Areas | Chemical storage tanks, water treatment, and food processing. |

| Maintenance Frequency | Recommended every 6 months to 1 year, depending on use. |

| Common Issues | Leakage, malfunctioning due to corrosion, or debris blockage. |

| Testing | Pressure testing and visual inspections recommended regularly. |

The Functionality of Vacuum Relief Valves in Different Systems

Vacuum relief valves play a crucial role in maintaining the integrity of various systems, especially in industries where pressure differentials can pose significant operational risks. These valves help to prevent negative pressure scenarios that may lead to structural damage, contamination, or operational failure. According to a report by the American Society of Mechanical Engineers (ASME), improper vacuum conditions can compromise equipment performance, resulting in costly downtime and repairs, emphasizing the need for regular maintenance and understanding of valve functionality.

In different systems—such as tanks, pipelines, and reactors—vacuum relief valves serve specific functions tailored to the unique characteristics of each application. For instance, in storage tanks, these valves permit the entry of air when a vacuum is generated due to product withdrawal, thus avoiding collapse. Meanwhile, in engineered systems like chemical reactors, maintaining appropriate pressure levels ensures reaction consistency and safety. As a general guideline, industry standards recommend inspecting vacuum relief valves at least once a year to ensure they are functioning properly and to mitigate risks associated with vacuum-induced failures.

**Tips:** Regularly check for leaks or signs of wear, as these issues can significantly reduce a valve's effectiveness. Additionally, establishing a routine maintenance schedule that includes testing the valves under operational conditions can help detect potential problems before they escalate. Staying informed about the specific requirements for various applications will further enhance system reliability and performance.

Common Issues and Troubleshooting for Vacuum Relief Valves

Vacuum relief valves play a crucial role in maintaining the integrity of systems that handle volatile compounds or gases. However, they are not immune to issues that can disrupt their functionality. Common problems include clogging due to particulate matter, mechanical malfunctions from wear and tear, and misalignment that prevents proper sealing.

According to a report by the International Society for Automation (ISA), about 20% of vacuum system failures can be traced back to faulty or improperly maintained relief valves. Regular inspection and maintenance can significantly reduce the frequency and severity of these issues.

Troubleshooting vacuum relief valves involves a systematic approach. Operators should first check for any visible signs of wear or damage and ensure that the valve is properly calibrated. A study published in the Journal of Vacuum Science and Technology indicates that calibrating valves at least once a year can enhance their performance and extend their lifespan. Furthermore, operators should be aware of the symptoms of malfunctioning valves, such as unusual fluctuations in system pressure or vacuum. Prompt identification of these issues is essential to prevent catastrophic failures and ensure safe operation. Proper maintenance practices, including routine cleaning and testing, can mitigate these common pitfalls and enhance the reliability of vacuum systems.

Maintenance Best Practices for Ensuring Valve Performance

Maintaining the performance of vacuum relief valves is critical for the safety and efficiency of any industrial process that relies on vacuum systems. According to a report by the American Society of Mechanical Engineers (ASME), improper maintenance and oversight can lead to valve failure, resulting in potential safety hazards and costly downtime. Regular inspections are essential for identifying wear and tear, ensuring that valves operate within their design specifications. Industry standards recommend performing these inspections at least bi-annually, but high-use environments may require more frequent checks.

Another best practice for valve maintenance includes the use of appropriate lubrication and replacement of seals and gaskets. According to the National Association of Corrosion Engineers (NACE), nearly 30% of valve malfunctions are attributed to corrosion and inadequate sealing. Utilizing high-quality materials that can withstand the specific environmental conditions can greatly enhance longevity and reliability. Additionally, documenting maintenance activities can improve operational transparency and facilitate compliance audits, contributing to overall system integrity and reducing the likelihood of unexpected failures.

Safety Considerations When Working with Vacuum Relief Valves

When working with vacuum relief valves, safety should be the foremost priority. These valves are critical components in a system that maintains appropriate pressure levels, working to prevent vacuum conditions that could lead to equipment damage or system failure. Understanding the potential risks associated with these valves can inform safer maintenance practices. For example, if a vacuum relief valve malfunctions or fails to operate correctly, it can result in dangerous pressure differentials that may cause explosions or implosions in certain applications.

When performing maintenance or inspections, operators must adhere to safety protocols to mitigate these risks. It is vital to ensure that the system is de-energized and fully depressurized before attempting any repairs. Wearing appropriate personal protective equipment (PPE), such as gloves and goggles, is essential to protect against potential hazards. Additionally, conducting regular training sessions for personnel on the proper handling and operation of vacuum relief valves can significantly enhance safety within the facility. By prioritizing these considerations, the likelihood of accidents and equipment failures can be greatly reduced, ensuring a safe working environment.

Understanding Vacuum Relief Valve Functionality and Maintenance

Related Posts

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

-

Understanding Vacuum Relief Valves for 2025 Top Applications and Benefits

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance