The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

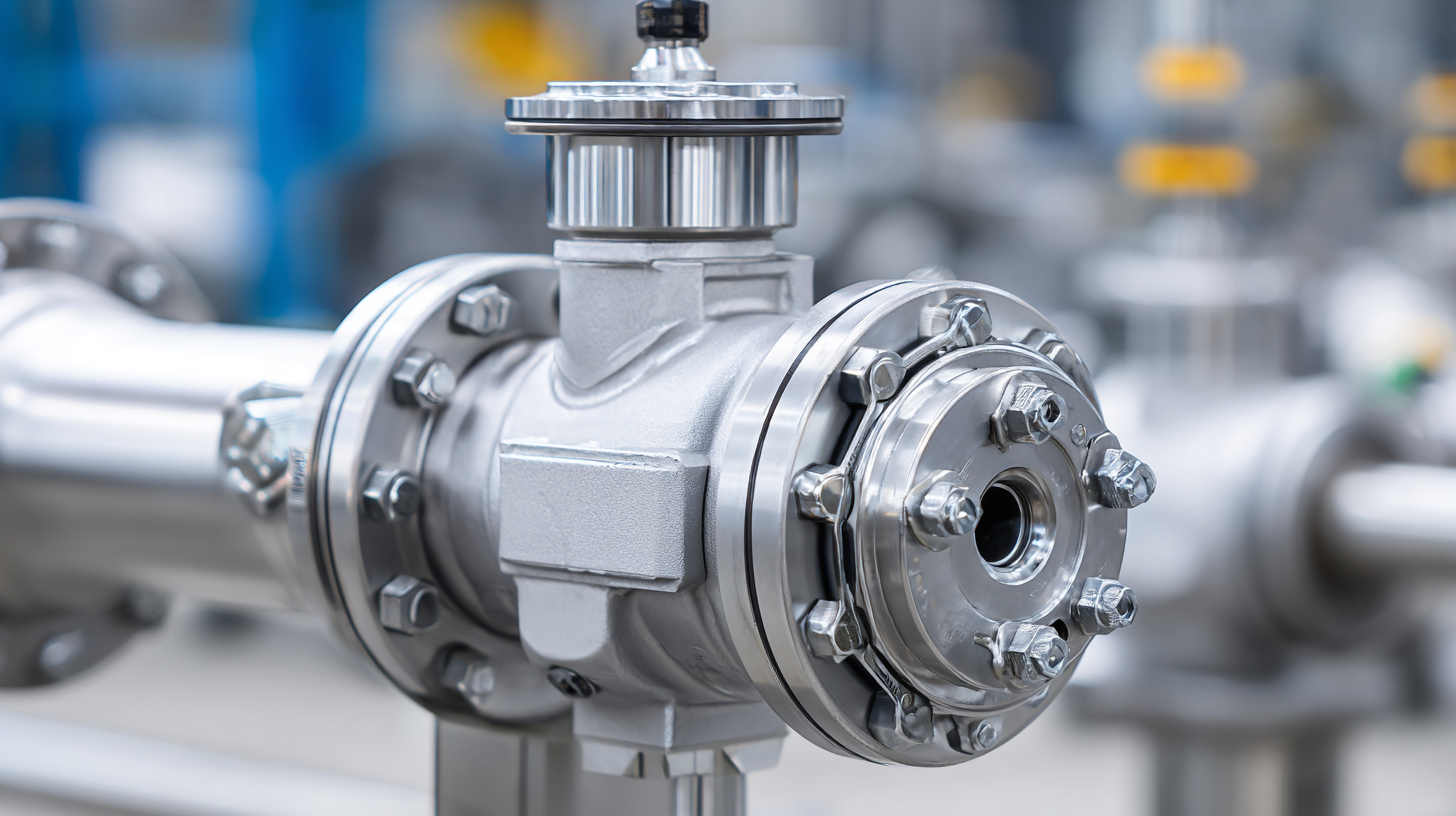

In industrial systems, ensuring safety and efficiency is paramount, and one critical component that plays a vital role in achieving these objectives is the vacuum relief valve. This essential device serves to regulate pressure fluctuations within equipment and pipelines, preventing catastrophic failures caused by vacuum conditions. As industries operate under varying temperatures and pressures, the risk of internal vacuum formation can compromise system integrity.

Vacuum relief valves act as a safety safeguard, allowing air to enter the system when negative pressure is detected, thus averting potential hazards such as implosions or equipment damage. In this article, we will explore the indispensable functions of vacuum relief valves, provide practical tips for their selection and maintenance, and highlight their importance in industrial applications.

Understanding the operational significance of vacuum relief valves is crucial for professionals seeking to enhance system reliability while prioritizing safety measures in their operations.

The Critical Importance of Vacuum Relief Valves in Industrial Operations

Vacuum relief valves (VRVs) play a critical role in industrial operations by preventing the formation of vacuum conditions that can lead to catastrophic failures. According to a report by the American Society of Mechanical Engineers (ASME), nearly 20% of industrial accidents stem from inadequate pressure control in piping systems. When a vacuum condition arises, it can cause structural damage, equipment failure, or even leaks of hazardous materials. This illustrates the pressing need for effective vacuum relief mechanisms in industrial environments.

Vacuum relief valves (VRVs) play a critical role in industrial operations by preventing the formation of vacuum conditions that can lead to catastrophic failures. According to a report by the American Society of Mechanical Engineers (ASME), nearly 20% of industrial accidents stem from inadequate pressure control in piping systems. When a vacuum condition arises, it can cause structural damage, equipment failure, or even leaks of hazardous materials. This illustrates the pressing need for effective vacuum relief mechanisms in industrial environments.

Furthermore, the U.S. Department of Energy highlights that proper implementation of VRVs can enhance system efficiency by maintaining optimal pressure levels during various operations. For instance, in the chemical processing sector, utilizing vacuum relief valves effectively can help minimize energy consumption by preventing excessive strain on pumps and compressors. Studies indicate that industries that incorporate VRVs effectively can achieve up to a 30% reduction in operational costs associated with equipment malfunction and maintenance. Ensuring the presence of these vital components not only enhances safety but also promotes overall efficiency in complex industrial systems.

Top 5 Benefits of Installing Vacuum Relief Valves in Industrial Systems

Vacuum relief valves (VRVs) are critical components in maintaining safety and efficiency across various industrial systems. One of the primary benefits of installing VRVs is their ability to prevent vacuum conditions which can lead to equipment damage or system failure. According to a report by the Chemical Engineering Journal, systems without proper vacuum relief can experience catastrophic failures that result in over $20 million in damages annually. By ensuring that the pressure within a system remains stable, VRVs help prevent such costly breakdowns and enhance the operational life of essential infrastructure.

Moreover, VRVs contribute significantly to energy efficiency in industrial processes. A study by the American Society of Mechanical Engineers highlights that systems equipped with vacuum relief technology can improve energy efficiency by up to 15%, as they reduce the energy consumed by pumps and other equipment trying to compensate for negative pressure. Additionally, by allowing for the controlled release of vacuum pressure, these valves help in maintaining the integrity of materials and prevent contamination, which is particularly crucial in sectors such as pharmaceuticals and food processing where standards are stringent. Thus, the strategic installation of vacuum relief valves is not only a safety measure but also a step towards increased operational efficiency and sustainability in industrial frameworks.

How Vacuum Relief Valves Prevent Equipment Damage and Ensure Safety

Vacuum relief valves (VRVs) play a critical role in maintaining safety and efficiency within industrial systems by preventing harmful equipment damages that may occur due to pressure variations. By allowing air or other gases to enter a vacuum system when pressure drops, these valves help avoid potential scenarios where the vacuum becomes too strong, leading to vessel collapse or other catastrophic failures. The tragic Byford Dolphin accident serves as a stark reminder of the lethal consequences that can arise from inadequate pressure management in high-risk environments. Ensuring the proper functioning of VRVs can significantly mitigate such risks and enhance overall operational safety.

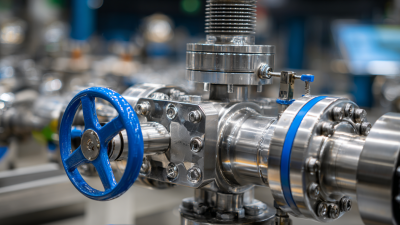

Additionally, recent advancements in valve technology further underline the importance of safety features in industrial applications. For instance, the introduction of automatic safety valves in chlorine gas handling improves the operational safety of hazardous materials, showcasing the influence of modern engineering in enhancing system reliability. By integrating sophisticated designs like these into industrial processes, companies can effectively reduce the likelihood of equipment failure, thus safeguarding both personnel and infrastructure from unforeseen accidents, reinforcing the essential role that vacuum relief valves play in creating a secure operational environment.

Key Factors to Consider When Choosing Vacuum Relief Valves

When considering vacuum relief valves for industrial systems, several key factors play a crucial role in ensuring both safety and efficiency. The demand for these components is projected to surge, with the global vacuum valve market estimated to reach USD 1.8 billion by 2026, up from USD 1.2 billion in 2021. This significant growth underscores the increasing recognition of the importance of properly functioning vacuum relief valves in protecting systems from potential damage due to vacuum conditions.

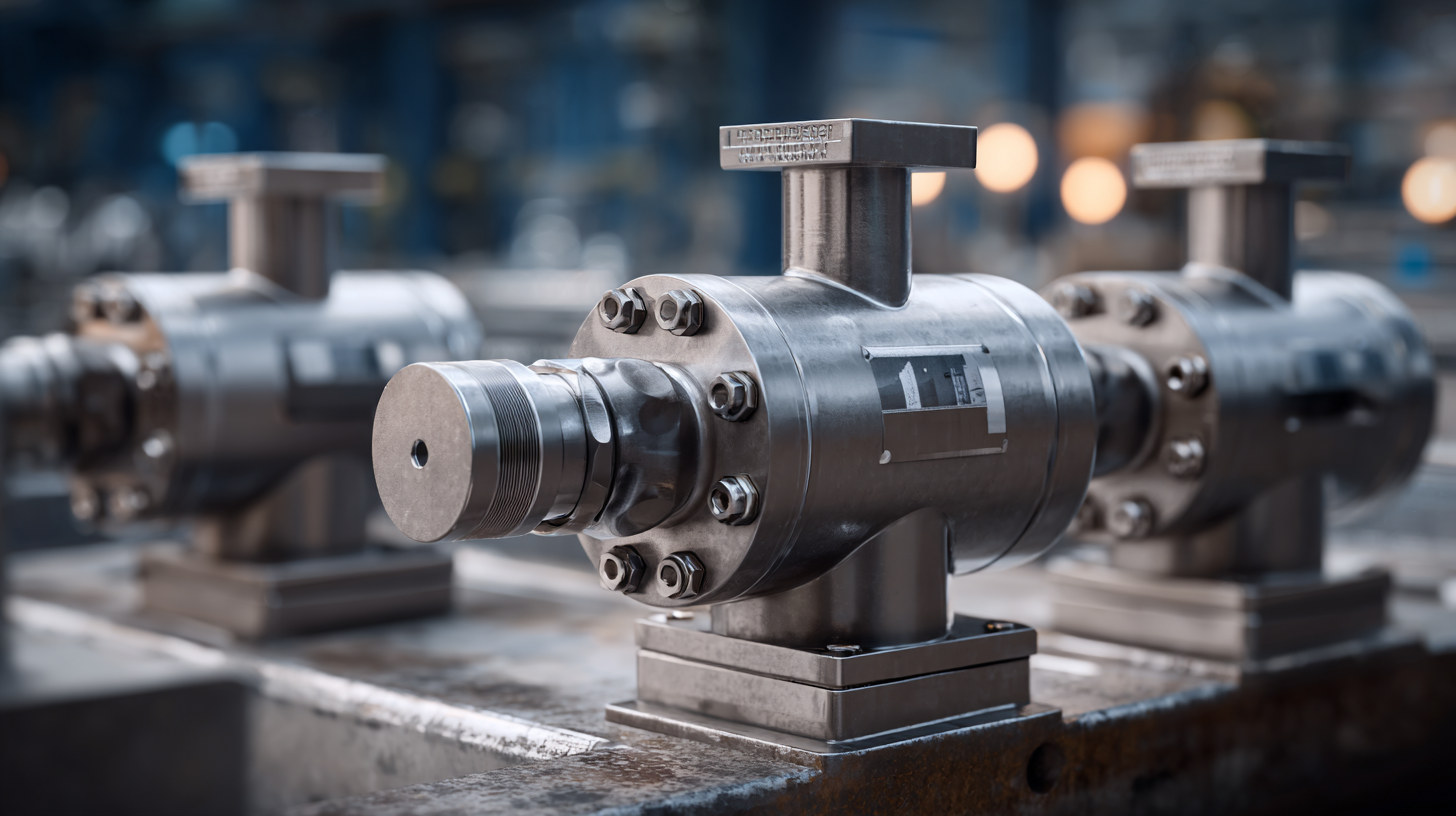

One of the primary factors to consider is the valve's pressure and temperature ratings. Selecting a valve that can withstand the operational conditions of your specific application is critical in preventing failures. Additionally, the material composition of the valve should align with the substances being processed, as compatibility can significantly affect durability and performance.

Furthermore, potential users should evaluate the maintenance requirements of the valves, as ease of service can impact overall operational efficiency. Investing in quality vacuum relief valves tailored to specific industrial needs is essential for advancing safety protocols and optimizing system performance.

Best Practices for Maintaining and Testing Vacuum Relief Valve Systems

Proper maintenance and testing of vacuum relief valve systems are critical for ensuring their effectiveness in industrial applications. Regular inspection should be a scheduled task, where the valves are examined for signs of wear and damage. Operators should check for any build-up of debris or corrosion that could impede the valve's function. It is also crucial to verify that the valve opens at the designated pressure to prevent vacuum-related failures. Any discrepancies must be addressed immediately to ensure optimal performance.

In addition to routine inspections, testing the vacuum relief valves under controlled conditions is essential. This can involve simulating various operational scenarios to confirm that the valves respond appropriately to changes in pressure. Documenting these tests provides a reliable record of the valve's performance over time. Furthermore, training personnel on the importance of these systems and how to conduct tests correctly ensures that safety protocols are followed diligently. By prioritizing maintenance and testing, organizations can enhance safety and efficiency in their industrial processes.

Related Posts

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications